The Manufacturing of Hot Rolled Stainless Steel Clad Plates for High-Performance Industries

July 9, 2025

Hot Roll Bonded Clad Plates are specially engineered bimetallic materials created by bonding two different metals under high temperature and pressure. This strong metallurgical bond combines the key benefits of both metals in a single plate, ensuring lasting performance. The smart design makes the most of each metal’s strength where it is needed most, offering a reliable, durable, and cost-effective solution. Due to this balance between strength and economy, clad plates are widely chosen across industries that demand high standards in safety, efficiency, and long-term reliability.

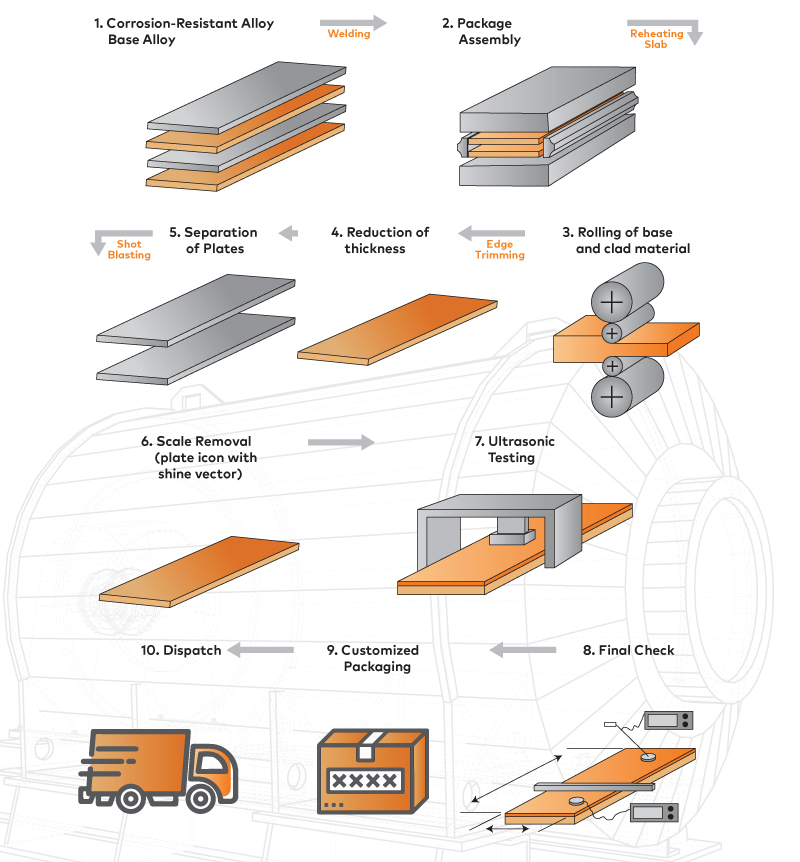

Manufacturing Process of HR Stainless Steel Clad Plates

The hot roll bonding technique is a widely adopted method for producing stainless steel clad plates, which combines the strength of carbon steel with the corrosion resistance of stainless steel. Below is a step-by-step outline of the process used in manufacturing this high-performance material:

Stainless Steel Clad Plate Specifications and Standards

Cladding alloys are designed to offer exceptional corrosion resistance and long-term durability, making them ideal for high-performance environments. The minimum thickness of the cladding alloy is 2.0 mm, with manufacturing tolerances conforming to ASTM A264 and A265 standards.

Available Grades

The available material combinations include stainless steel, nickel alloys, and carbon or alloy steels. Some typical grades used in cladding applications are:

- Stainless Steel and Carbon Steel / Alloy Steel

- Nickel Alloy and Carbon Steel / Alloy Steel

- Nickel Alloy and Stainless Steel

Base materials include IS 2062 (grades E250 to E450), EN 10025 (grades S235 to S450), ASTM A36, A283/284/285, A588, and ASTM A516 (Grades 55 (380), 60 (410), 65 (450), 70 (485)). API 5L grades from Grade B through X-70 are also available.

Dimensional Range:

| Thickness(mm) | Width (mm) | Length (mm) |

| 8.0 – 20.0 | 1000 – 1200 | Up to 8000 mm |

Testings that Enhance the Quality of Stainless Steel Clad Plates

Clad plates undergo rigorous testing and inspection procedures to ensure exceptional quality and long-term performance.

1. Tensile Test

To evaluate the material’s strength, a tensile test is carried out either on the composite plate or the base plate.

2. Bend Test

A bend test is conducted with the cladding metal on the outside. This test is specifically designed to assess the bonding strength between the cladding layer and the base material.

3. Shear Strength

The shear strength of the bonded layers is tested to confirm structural reliability. As per the ASTM specifications, the minimum required shear strength for clad plates is 140 MPa.

4. Ultrasonic Test

Ultrasonic testing is performed to detect any internal discontinuities. It is performed as per ASTM A264/A265.

5. Corrosion Test

To guarantee the corrosion resistance of the cladding material, specific corrosion tests are conducted. For stainless steel cladding, testing is done in accordance with ASTM A262 Practice E. In the case of nickel alloy cladding, the procedure follows ASTM G48 Method A.

Typical Fields Of Application

- Chemicals & Pharmaceutical:

- Reactors

- Process columns

- Vessels

- Pipings

- Oil & Gas:

- Vessels

- Clad pipelines

- Coke drums

- Heat exchangers

- Power:

- Flue stack

- Heat exchanger

- Flue gas desulphurisation

- Renewables:

- Penstock pipes

- Radial & vertical gates

Hot-rolled Clad Plates for Strength and Resilience

Hot-rolled stainless steel clad plates are a versatile and durable solution for industries requiring both the strength of carbon steel and the corrosion resistance of stainless steel. With rigorous testing procedures, these plates meet strict quality requirements for mechanical performance, corrosion resistance, and structural integrity, making them a reliable choice for applications where both performance and longevity are key.

For detailed specifications, grade options, and application insights, download the full PDF.