Monthly

Stainless Trivia

Fill in your answer below

A LEGACY BUILT ON SAFETY & TRUST

Founded by Shri OP Jindal in 1970, Jindal Stainless (comprising Jindal Stainless Limited and Jindal Stainless (Hisar) Limited) has an annual melt capacity of 1.9 MT and an annual turnover of US $4.20 billion (as of March'22). Already in its expansion phase, the Company’s annual melt capacity will reach 2.9 MT by the end of FY23. Integrated operations, from mining to manufacturing of finished products, have given Jindal Stainless the edge of cost competitiveness and operational efficiency, making it one of the best stainless steel producers in the world.

Jindal Stainless continues to be inspired by a vision for innovation and enriching lives. The magnitude of its operations determines its brand credibility. The Company boasts of an excellent workforce, value-driven business operations, customer centricity, adoption of one of the best safety practices in the stainless steel industry, and a commitment for social responsibility.

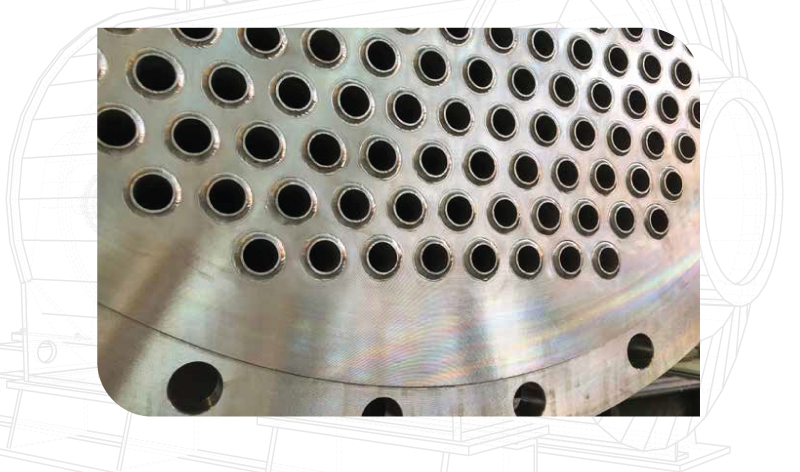

HOT ROLL BONDED CLAD PLATES

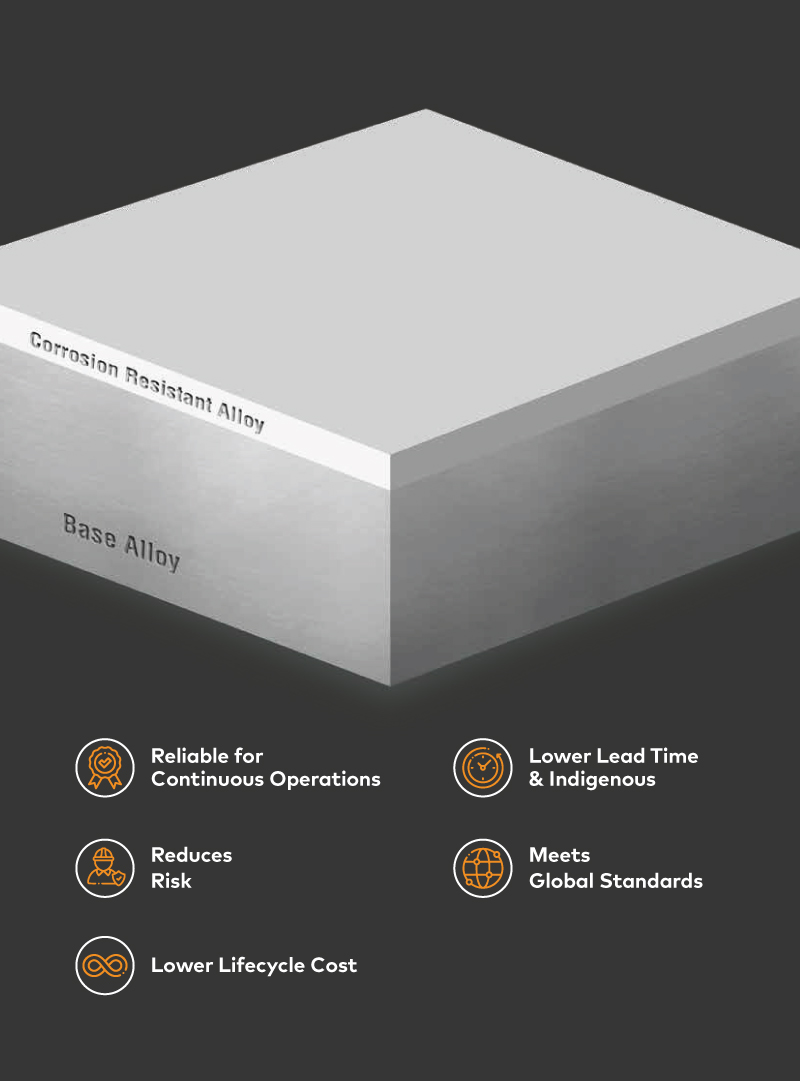

Hot Rolled Clad Plates are metallurgically bonded composite of two layers produced through roll bonding which is done by hot rolling a welded composite assembly of steel clad plates.

- The bond is created by high temperature and high pressure during hot rolling

- A typical combination is a thin corrosion-resistant alloy (CRA) as clad material and a thick carbon steel as base material

Clad stainless steel plate is used in a variety of industrial fields like Oil & Gas production & refining construction, and chemical, Pharmaceutical, and Flue gas desulphurization industry for various equipments.

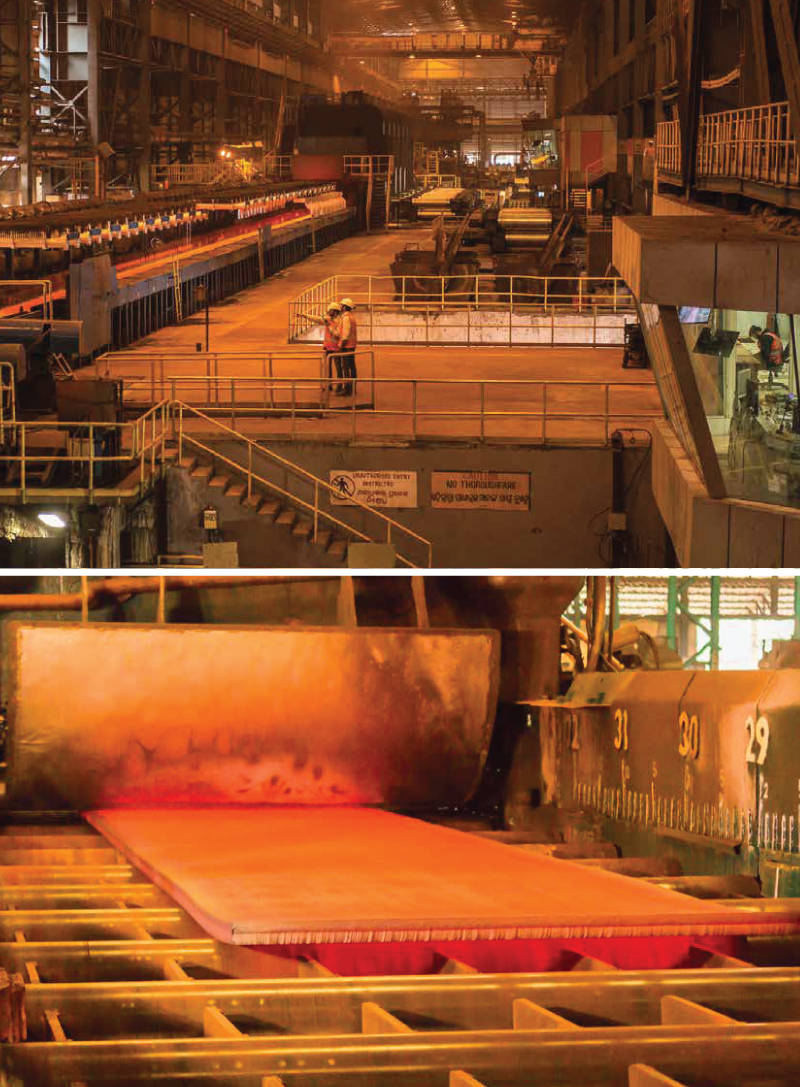

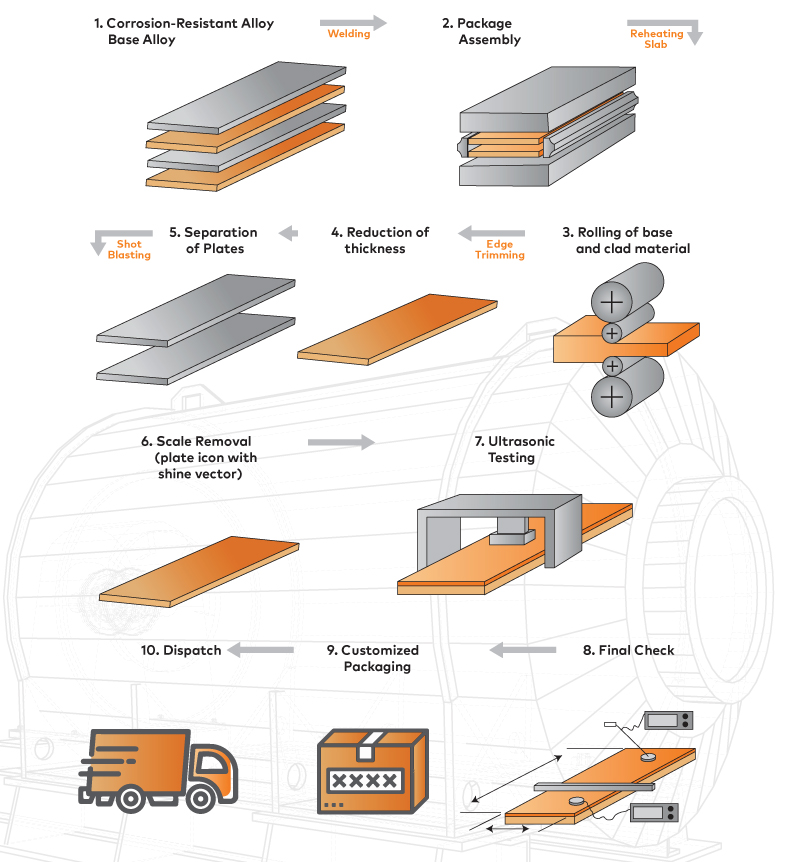

HOT ROLL BONDING PROCESS

Our production equipment is highly automated and provides precise tolerances concerning dimensions, flatness and surface quality & properties

CORROSION RESISTANT ALLOYS FOR UNPARALLELD STAINLESS SECURITY

Corrosion-resistant alloys

Austenitic stainless steel

Grades 304/L,304LN,309S,310S, 316/L,316LN,316Ti,317L,317LN,321/H,347/H

(Standards As per ASTM,ASME, JIS & EN)

Nickel Alloys

Grade: UNS N10276 & Other Nickel alloys

| Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|

| 8.0 - 20.0 | 1000 -1200 | Up to 8000 |

Minimum thickness of cladding alloy is 2.0 mm.

Tolerances as per ASTM A264, A265

Contact our JSL representative for any customized requirement

TYPICAL BACKING STEEL

- IS 2062: E250 to E450

- EN 10025: S235 to S450

- ASTM A36, A283/283/285, A588

- ASTM A516: Grades 55 (380), 60 (410), 65 (450), 70 (485)

- API 5L Grade B, API 5L X-42/X-46/X-52/X-56/X-60/X-65/X-70

TESTING & INSPECTION

MULTIPLE CHECKS FOR ULTRA DURABILITY

Testing and inspection of Clad Plates are performed in accordance with the specification of ASTM A264 and A265.

> Tensile Test:

The tensile properties shall be determined by a tension test of the composite

plate or base plate for evaluation of strength of material.

> Bend Test:

Bend tests with the cladding metal outside indicate the strength of the bond.

> Shear Strength:

The ASTM specification requires minimum shear strength of 140 MPa.

> Ultrasonic Test:

Ultrasonic inspection is performed as per ASTM A264/A265

> Corrosion Test:

ASTM A262 Practice E for Stainless steel cladding material

ASTM G48 method A for nickel alloy

CONTACT DETAILS

Kolkata

3A, Duckback House

41, Shakespeare Sarani,

Kolkata - 700017

Tel : +91 - 9073352568

Fax : +91 33 - 22906203

Mumbai

Jindal Mansion, 1st Floor, 5A,

G. Deshmukh Marg (Pedder Road)

Mumbai- 400026

Tel : +91 - 9561094183

Pune

209, Regent Plaza, 2nd Floor,

Baner - Pashan Link Road,

Baner, Pune - 411045

Tel : +91 - 9811395126

Vadodara

902-903, Samanvay Sliver

Near Sivaji Circle, Mujmahuda,

Vadodara - 390020

Tel : +91 - 9833214396

Fax : +91 - 265 - 2225004

New Delhi

Jindal Centre, 12, Bhikaiji Cama Place,

New Delhi - 110066, India

Tel : +91 - 9099020161

Fax : +91 - 011 41659169

Hisar

OP Jindal Marg, Hisar - 125005,

Haryana, India

Tel : +91 - 9896648952

Fax : +91 1662 220476, 220499

Jaipur

Kalinga Nagar Industrial Complex,

Duburi, Dist. Jaipur - 755 026,

Odisha, India

Tel : +91 - 9971084405

Ahmedabad

Jindal Stainless Ltd.

401 - 402, Florence,

Opposite Ashram Road Post Office,

Ashram Road, Ahmedabad – 380006

Tel: +91 - 8377991647

Bhubneshwar

14, Forest Park, Airport Road,

Bhubneshwar, Khurda - 751009

Tel : +91 - 9971084405

Chennai

“HEVITREE”, 1st Floor, No. 47,

Spurtank Road, Chetpet - 600031

Tel : +91 - 9962297111

Gurugram

Stainless Centre

1st Floor, Plot No. 50, Sector - 32,

Gurugram - 122001

Tel: +91 - 9099020161

Hyderabad

H. No: 1-10-74/C, Flat No: G 201/A,

2nd Floor Technopolis Galada Complex

Begumpet, Hyderabad 500016

Tel : +91 - 9491073529

email: infinity@jindalstainless.com

www.jindalstainless.com

visit www.makestainless.com for suppliers

of consumables, fasteners and fabricated

components.