Sustainable Engineering from principles to practise with Jindal Stainless

September 19, 2023

In a world facing unprecedented environmental challenges, the role of engineers has evolved beyond conventional problem-solving. Enter sustainable engineering: a dynamic field that not only seeks to innovate but also to harmonise human progress with the planet’s well-being. What can be a better way to celebrate Engineer’s Day than talking about what is sustainable engineering, famous global case studies, and what sustainable engineering looks like in Jindal Stainless?

What is Sustainable Engineering?

Sustainability has become increasingly important, with the demand for environmentally friendly solutions at an all-time high. As a result, businesses and innovators from across the world are coming together to develop sustainable engineering solutions that do not compromise our natural environment. It’s a movement that champions design with minimal environmental footprints, facilitates resource efficiency, and mitigates harm through holistic problem-solving. It’s about engineering structures that endure without causing harm, systems that function efficiently without wasting resources, and innovations that enrich human lives without compromising future generations. In essence, understanding sustainable engineering means acknowledging that every engineering decision has far-reaching implications. It’s engineering with a conscience, engineering for a world where the symphony of human achievement harmonises with the chorus of nature.

Masdar City UAE: A Mirage Turned Rality

In the heart of the desert of UAE, Masdar City defied nature’s constraints, rising as a beacon of sustainable urban planning. Driven by sustainable engineering principles, it boasts smart systems that meticulously monitor and optimise energy usage, while innovative technologies recycle water and manage waste. The result? A city that consumes 40% less water than its peers and proudly sends no waste to landfills.

Smog Vacuum cleaner creates jewellery

Dutch designer, Daan Roosegaarde, built and developed the world’s first smog-free tower in Rotterdam in 2015 after being shocked at the levels of air pollution in big cities. The award-winning tower acts as a giant vacuum cleaner, sucking in polluted air, cleaning it through a process of ionisation, before releasing it back into the atmosphere. At peak performance, the tower can clean around 30,000 m3 of air every hour! More recently, Roosegaarde developed a technique that takes carbon-filled smog particles produced by the tower and compresses them to create jewellery such as rings and cufflinks. Each piece of jewellery contains smog dust from 1,000 m3 of polluted air.

Scrap Metal reduction through electrodialysis

British Engines Group Company, CMP Products has installed EDEN® electrodialysis technology at its nickel processing plant to extend the life of its nickel plating baths. Electroless nickel (EN) plating is a process that uses a chemical reaction to create a nickel deposit on a component. During the plating process, by-products of the chemical reaction build up and decrease the performance of the metal baths where the plating takes place. The EDEN® electrodialysis unit selectively removes contaminants to regenerate the metal baths, allowing them to be used again. This has resulted in a substantial decrease in the number of EN baths being scrapped, significantly reducing the environmental impact of CMP’s nickel plating process.

Innovations and Technologies: Transforming Manufacturing for Sustainability

Within the manufacturing industry, sustainable engineering innovations and technologies are revolutionising processes, products, and the entire supply chain. These advancements do not just drive sustainability but also enhance efficiency, reducing costs and ensuring compliance with evolving environmental regulations. Lean manufacturing and industrial automation streamline processes, reducing waste and energy consumption. The adoption of eco-friendly materials, closed-loop systems, and circular economy practices is minimising environmental footprints and fostering responsible resource use. Integration of renewable energy sources and energy-efficient machinery is decreasing carbon emissions while cutting operational costs. Additionally, transparent supply chains and green logistics practices enhance sustainability from sourcing to delivery. The adoption of all these innovations will lead to environmental responsibility, cost efficiency, and the creation of durable, eco-conscious products.

Engineering a greater tomorrow: Jindal Stainless Sustainable Initiatives

At Jindal Stainless, our commitment to sustainability is resolute, beginning right from the design phase and extending through every step of our operations. We prioritise the efficient utilisation of resources and have implemented various eco-friendly measures, including the utilisation of Waste Heat Recovery Boilers for energy conservation, the establishment of a Phenolic Effluent Treatment plant to achieve Zero Liquid Discharge, the implementation of an INBA slag granulation and dewatering system to promote the reuse of slag, optimisation and vigilant management of water resources, and the implementation of effective waste management practices to name a few. These initiatives collectively reflect our resolute commitment to sustainability and our endeavour to green our operations for a more eco-conscious future.

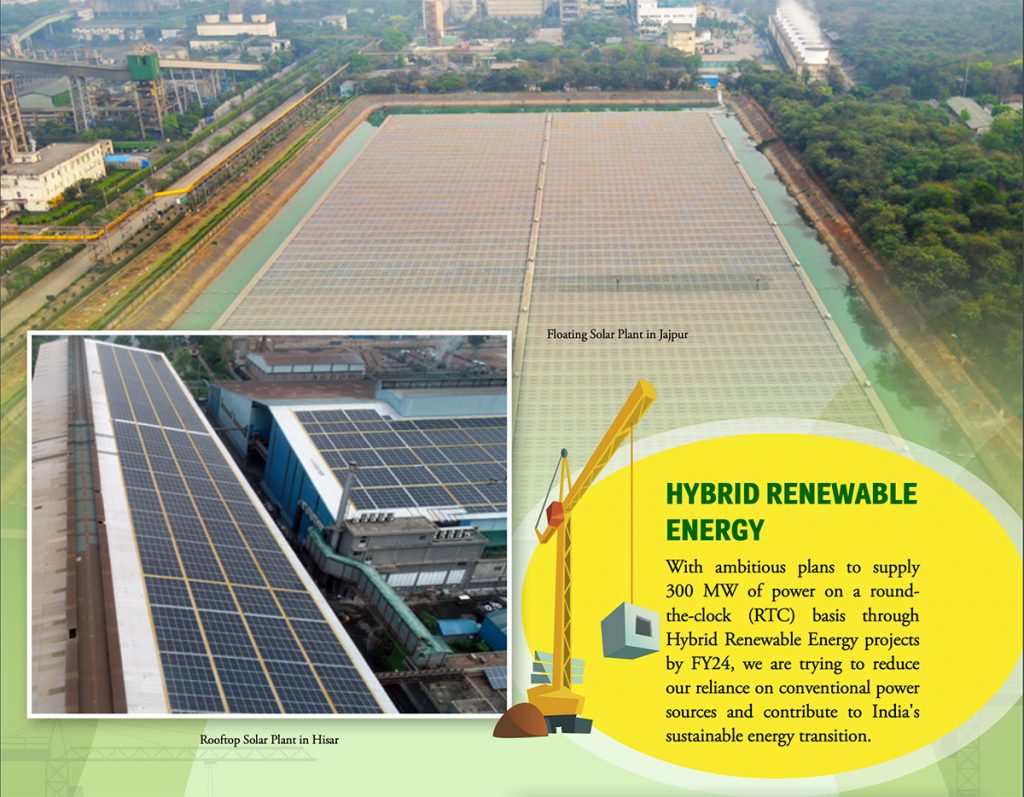

Solar Power Innovation

The installation of Odisha’s first fully captive floating solar plant in Jajpur, boasting a substantial 7.3 MWp capacity, exemplifies our commitment to sustainable power generation. We have successfully installed 13.86 MWp Rooftop Solar plants, further reducing our carbon footprint. Plans are underway for rooftop solar installations of 21 MWp in Jajpur and 6 MWp in Hisar.

Green Hydrogen Revolution

Jindal Stainless stands as India’s first stainless steel manufacturer to establish a Green Hydrogen Plant, producing 90 Nm3/hr of this eco-friendly fuel at Hisar. Furthermore, plans are underway for another Green Hydrogen Plant, with a capacity of 700 Nm3/hr, to be installed in Jajpur.

Exploring CCUS

We are actively exploring Carbon Capture Utilisation and Storage (CCUS) systems, acknowledging the importance of capturing and managing carbon emissions as part of its sustainable engineering approach.

Sustainable Sourcing

With a focus on responsible sourcing, Jindal Stainless domestically procures 65-70% of its stainless steel scrap and 100% of other raw materials. This strategy not only promotes local economies but also reduces the environmental impact of global transportation.

Community Impact

Beyond its environmental efforts, Jindal Stainless is also dedicated to societal impact. The company aspires to touch the lives of one million people through its Corporate Social Responsibility (CSR) initiatives by the end of the decade.

While we celebrate the milestones we’ve achieved in sustainable engineering, we must also acknowledge that our journey is far from over. The challenges posed by climate change and environmental sustainability remain formidable, and there is much more work to be done. As we move forward, our commitment to reducing our carbon footprint, expanding our use of renewable energy, and exploring new frontiers in sustainability remains resolute. With each step, we contribute to a better, more sustainable future for all.