Sudhir Kumar

April 9, 2019

‘You can’t eliminate every hazard, but the closer you get to that goal, the safer you make the environment for your people.’ – Safety team of Jindal Stainless

If you reach home safely at the end of your workday, Congratulations! You made it through yet another day; a lot of people don’t get this lucky. The credit for keeping you safe and sound of course goes to you but it wouldn’t be possible without the incessant efforts of our Safety Stalwarts. Most of us have no clue about what goes on in the safety department; a department which has complete authority to shut down operations if a hazardous situation exist. But, such great power comes with great responsibility. They are responsible for the health and safety of everyone who works in and visits our plant premises – be it employees, visitors or customers.

The Safety and Fire Department comprises of safety officers, fire officers, plant specific safety champions and safety stewards. An area-wise safety responsibility matrix and world class systems and procedures are at play to make the work place safe for us. Get a glimpse of what it’s like to be a safety officer below!

In Conversation with Hisar’s Head, Environment, Health and Safety, Mr Sudhir Kumar; DGM, Safety – HR, Mr Narendra Gupta; DGM, Safety – CR, Mr Amulya Biswas, and Jajpur’s Head Safety and Fire, Mr M L Panda

1) What Does An Average Day Look Like For A Safety Officer?

Hisar Team: We never know what the day will bring. The first drill of the day is to examine the daily reports which indicate if anything is out of order or potentially hazardous. These observations are made by the safety officer and night duty officer for the necessary action to be taken. There are certain high-risk jobs (hot work, working at a height or in a confined space) other than routine jobs which require a work permit, and on an average day we usually receive 50 work permits for consideration. We have to identify all the possible hazards and risks before and during the execution of any activity and control them. Only after all risks are mitigated, we issue permits for work to begin. For sensitising employees and preparing them for emergency situations, we conduct at least 4 mock drills per month. It is mandatory that every department should be covered once in six month.

Jajpur Team: Our day also involves routine inspections, dealing with complaints and incident reports from employees, compiling reports, and putting together health and safety programmes for the employees. We monitor our employees’ adherence to Standard Operating Procedures (SOPs) and Personal Protective Equipments (PPEs) on a daily basis, in every nook and corner of our plant. Another thing that takes significant mindshare is conducting trainings for induction or specific job requirements, and constantly updating and reinventing these training programmes for our employees.

2) Tell Us About The Some Key Initiatives And Activities Started By The Safety Department For Accident Prevention At Jindal Stainless.

Jajpur Team: A dedicated Safety Training Centre (STC) well equipped with multimedia facilities has been established to impart audio-visual aided induction and job specific safety trainings daily.

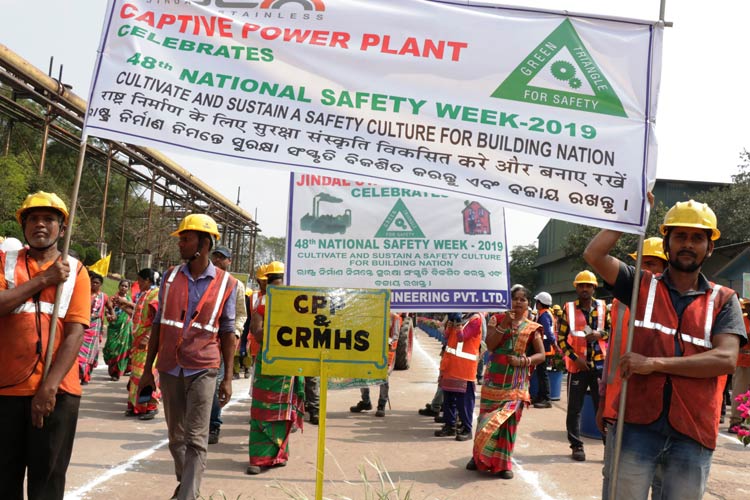

Various safety promotion campaigns and awareness drives are undertaken at regular intervals to instil a culture of safety. These include daily safety messages through Pulse, plant-wide displays of slogans and safe work instructions, quizzes, essays and poster competitions, observing National Safety Day etc.

Regular demonstrations of usage of PPEs like full body harness, life line, fall arrestor, rescue operations also take place.

Weekly open house safety meetings at different shop floors are chaired by the plant head.

An Emergency Control Room (ECR) has been earmarked near Main Fire Station. It is also worth mentioning that through our employees’ dedicated effort through the years, ‘zero fatality’ target has been achieved at Jajpur.

To further digitise the Safety Management System, we are planning to install several CCTV surveillance cameras and a ‘Smart Fencing System’. An online monitoring system of all toxic gases for the entire complex is also in the pipeline.

Hisar Team: We have developed an EHS Calendar where every month will be dedicated to a particular theme of safety. Throughout the year, we run various safety promotion campaigns and awareness drives to strengthen our safety orientation. We have also on-boarded a high quality public address system for dealing with safety and security challenges.

Safety skill enhancement of employees is a key priority for us; at least 14 hours per year per person are dedicated to safety training.

We have started monitoring jobs at heights using a drone camera. We also have in place a fall-arrestor system for ensuring the safety of those working at heights.

We have initiated safety messaging through reflective and digital boards, standardization of fencing and guarding machinery as per Indian Standards and upgrading the Fire and Emergency system of our buildings in accordance with Building code 2016.

Development of Authorized Operating License for driving inside the plant premises, upgradation of our online safety portal, revamp of our CO2 flooding system and marking and fencing of walkways and gangways along the roads are some other major initiatives.

3) What Are The Major Challenges That You Face In Your Professional Life?

Hisar Team: Most of the workmen are technically sound but sometimes violate safety regulations. The earlier reaction to violating safety rules used to be, “Chalta hai sahab!” (This is okay too, Sir!) Overcoming this mentality was our biggest challenge every day. Nobody ever enjoys having their work interrupted or to be called out for their mistakes, even though everyone makes mistakes. Hence, people usually don’t like safety officers. But like they say, “You can like us or you can despise us, but you cannot avoid us”. We have to be patient and take a more personal and motivational approach with every individual when it comes to ingraining the fundamentals of safety.

Jajpur Team: The major challenge of any safety department is moulding the behaviour of employees towards safety. Though it will take time to change people’s behaviour, we are trying our best to catalyse this change at the grass root level. The safety and protection of people, equipment and the environment is a serious concern in the industrial setup. For this reason, the Safety Management system should act as a proactive and systematic way for identification, evaluation, mitigation, prevention and control of hazards to ensure safety and risk management. Therefore, we urge everyone to come together and contribute to meet the objectives of safety standards.

4) Any Advice To Budding Engineers And Members Of Our Stainless Family?

Jajpur Team: I urge all our employees to make the safety drive a successful movement and hope that its benefit reaches every individual. I pray that Jindal Stainless remains as a ‘zero-accident’ company for times to come.

Hisar Team: It is the responsibility of the engineers to look after the safety of the workers and that of the environment around them. You’ll be under a lot of pressure to complete the work on time and you might be tempted to skip some safety measures to complete the task. But, safety always comes first. If a human being has an accident and loses a body part or worst, their life, you can never bring them back! After all, precaution is always better than cure.