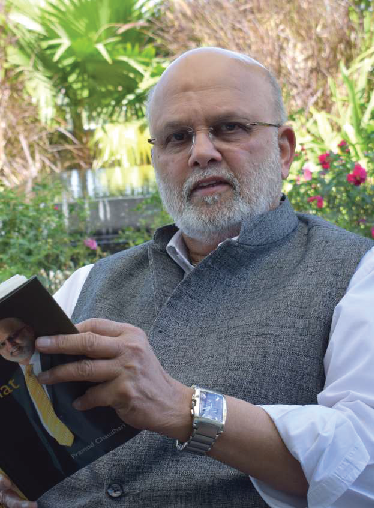

Mr Pramod Chaudhari

April 16, 2018

He is a nationalist in an influencing entrepreneur, a dreamer who dreamt with open eyes and went full throttle to make his dreams come true: and a leader who inspired many with his compelling life-story. Read how an IITian lad emerged to have become one of the leading entrepreneurs in Engineering sector.

I thought I should jump the ladder and start my own firm

Tell us something about your background.

Executive Chairman, Praj Industries

I hail from an interior part of Phaltan in Satara, Ahmednagar district of Maharashtra. My father worked in a sugar mill and my mother was a teacher. We are three siblings, with two sisters, and belonged to a typical middle class family. After I completed my schooling from Pune, my excellent academic record secured me a seat in IIT-Mumbai and I graduated as a mechanical engineer. During that time IITians were famous for becoming expatriates, and 80% students from my batch did move abroad. However, the roots to which I belonged kept me grounded, and I took up a job in Pune in an automobile company, then called Bajaj Tempo. After a five year stint in my first job, I moved on to join a German company, now known as Kennametal, which was involved in tooling and industrial materials. I worked for almost 12 years with these two firms, however, the dream of becoming an entrepreneur still tugged at my heart. I thought I should jump the ladder and start my firm. I always had an inclination to do something for the environment, agri processing and energy conservation. Remember, India was under a license Raj in the mid 80s and it was not easy to start a business. While ruminating once, I went back to my native land, where I studied and watched sugar mills very closely. My passion to do something for our agriculture sector and the love towards my nation was strong enough to provide me the trigger and I decided to do something of my own in agricultural processing. In 1983-84, I finally realised my dream by setting up my own company.

From a dreamer to an entrepreneur, what was this journey like?

It was taxing but an enlightening journey. In the early phase, we were able to collaborate with an Austrian company for advance technology. We were the first Indian engineering company to raise venture capital from ICICI way back in 1987 when venture capital was totally a new concept in India. We got a support of mere 45 lakh rupees, but it was a major shot in the arm for us to initiate the commercialisation of our technology. We were aiming at ethanol technology as our specialisation in the agri processing segment. It is a bio-chemical process and we were introducing continuous fermentation technology, first of its kind, in the early 90s. We could see the positive results in just 3-4 years, as the industry was yielding well in terms of productivity and energy saving. In 1991-92 we emerged as the leader in this space and this gave us more confidence. In the meanwhile, our venture capital team advised us to plan an IPO and luckily our fund raising exercise coincided with liberalisation of the Indian economy. It was a great moment for all of us. We were confident that our funding issue will get resolved after the IPO and we can easily expand our business. Now it was then that we added a few other business lines including brewery. We expanded our footprint overseas for the first time in the South-East Asian region with an office in Singapore, and subsequently started looking for opportunities in the Philippines, Indonesia and Thailand region. We got recognised for our niche technology and responses from the customers were encouraging. It was a notable achievement for an Indian company like ours.

What are some notable trends and changes in your industry?

When I started my business, high quality beverages were in demand in the market. Alcohol got the second important chance in our industry when it was declared bio additive to petrol. This was a major transformation for the brewery industry. We were quick to catch the change. Alcohol was blended with petrol and this happened because of a few reasons. Firstly, it was a replacement to crude oil as it depletes forex reserves of a country, and secondly alcohol provides a renewable fuel source. Thirdly, addition of alcohol in petrol makes the fuel cleaner as the exhaust from the petrol is much cleaner without any particulate matter. Pollution in cities like Mumbai and Delhi can be controlled by this. Ethanol blended petrol changed our fortunes, and because of our leadership in this segment we were ahead of the rest. We expanded our product range to South America, Europe and US, after our successful South East Asia experience.

How do you foresee the future panning out for your industry?

There is new advent in last 4-5 years which is taking shape as a second generation technology. Now, there is an emerging trend to use agri waste in the form of left overs in the field to produce ethanol. This is a major development in our sector and Praj has been in the forefront. Delhi gets brown clouds in Nov-Dec because of Paddy burning in Haryana and Punjab fields. Praj has successfully developed a technology to use this left over to produce ethanol. Two projects have been initiated using this technology. It is a major breakthrough, which is developed in-house at our R&D centre in Pune. This technology is now drawing attention of our foreign customers who are interested to explore this further. We plan to go global with this technology soon.

What sets Jindal Stainless apart?

Our huge agri processing equipments are prone to corrosion. Therefore, we need an anti corrosive material like stainless steel, and require high quality stainless steel for our equipment. Timely delivery and competitive prices make Jindal Stainless our first choice. Moreover, Jindal Stainless provides customisation as per our requirements. Mostly, we require plates and sheets in specific size, thickness and width. Jindal Stainless has always responded and understood our needs. We have technical experts of Jindal Stainless visiting us once in a while to discuss product specifications with our in-house designers. Customer-oriented service keeps Jindal Stainless ahead of others.

What is your message to future generations?

I will share my personal experience that has helped me a lot. Apart from hard work, individual curiosity is equally important and one should know why and how things are happening around you. Having this trait of inquisitiveness is vital to make it big in life. The way technology is advancing, this trait will help us question and challenge new developments, thereby making us aware and prepared for the future. My second message is about the consciousness towards environment. I personally want our young managers to have a responsible attitude towards our depleting natural resources. Let’s remember that we don’t inherit the world from our parents, we borrow it from our children. At Praj, I try to walk this talk every day, so that our life becomes our message.