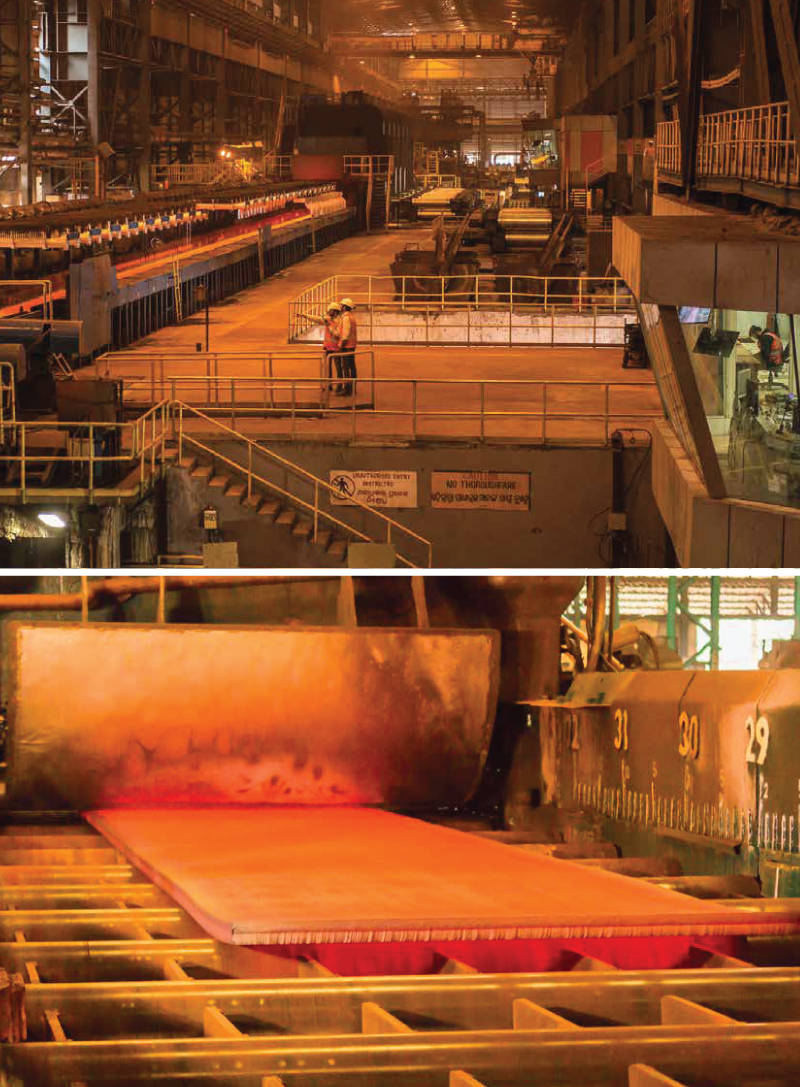

HOT ROLL BONDED CLAD PLATES

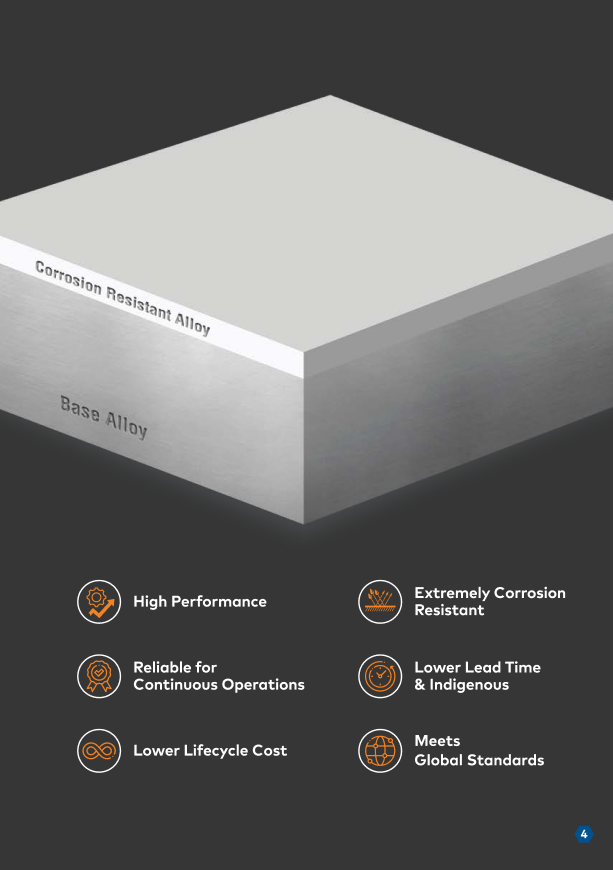

Hot Rolled Clad Plates are metallurgically bonded composite of two layers produced through roll bonding which is done by hot rolling a welded composite assembly of steel clad plates.

- The bond is created by high temperature and high pressure during hot rolling

- A typical combination is a thin corrosion-resistant alloy (CRA) as clad material and a thick carbon steel as base material

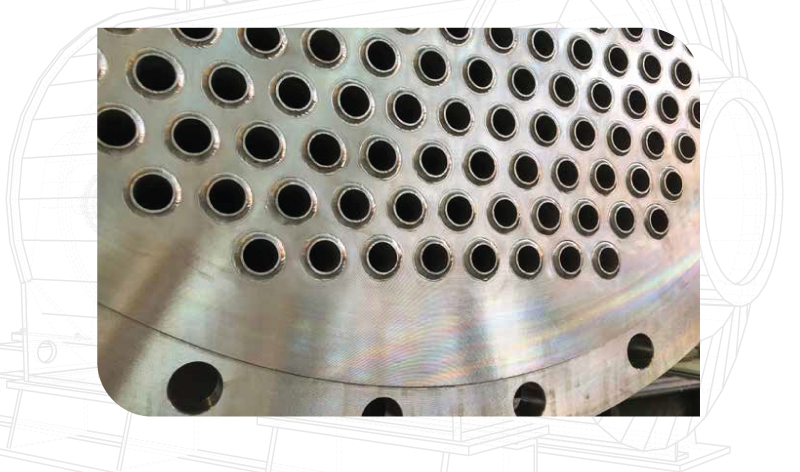

Clad stainless steel plate is used in a variety of industrial fields like Oil & Gas production & refining construction, and chemical, Pharmaceutical, and Flue gas desulphurization industry for various equipments.

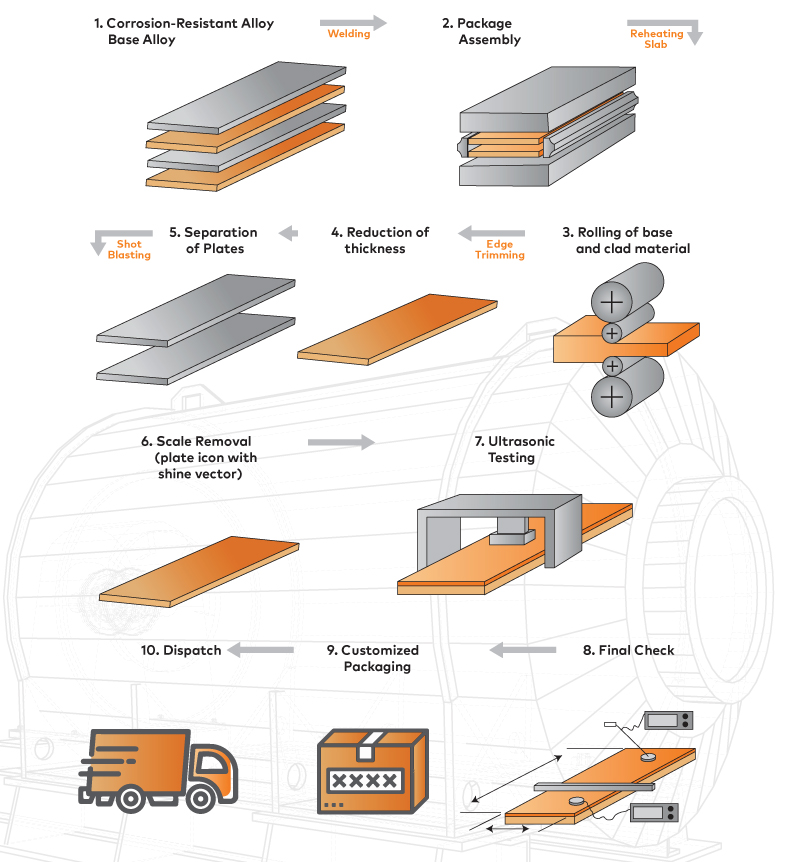

HOT ROLL BONDING PROCESS

Our production equipment is highly automated and provides precise tolerances concerning dimensions, flatness and surface quality & properties

CORROSION RESISTANT ALLOYS FOR UNPARALLELD STAINLESS SECURITY

| Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|

| 8.0 - 20.0 | 1000 -1200 | Up to 8000 |

Minimum thickness of cladding alloy is 2.0 mm.

Tolerances as per ASTM A264, A265

Contact our JSL representative for any customized requirement

TYPICAL BACKING STEEL

- IS 2062: E250 to E450

- EN 10025: S235 to S450

- ASTM A36, A283/283/285, A588

- ASTM A516: Grades 55 (380), 60 (410), 65 (450), 70 (485)

- API 5L Grade B, API 5L X-42/X-46/X-52/X-56/X-60/X-65/X-70

TESTING & INSPECTION

MULTIPLE CHECKS FOR ULTRA DURABILITY

Testing and inspection of Clad Plates are performed in accordance with the specification of ASTM A264 and A265.

> Tensile Test:

The tensile properties shall be determined by a tension test of the composite

plate or base plate for evaluation of strength of material.

> Bend Test:

Bend tests with the cladding metal outside indicate the strength of the bond.

> Shear Strength:

The ASTM specification requires minimum shear strength of 140 MPa.

> Ultrasonic Test:

Ultrasonic inspection is performed as per ASTM A264/A265

> Corrosion Test:

ASTM A262 Practice E for Stainless steel cladding material

ASTM G48 method A for nickel alloy