Smart Infrastructure Starts with Stainless Steel

May 15, 2025

With its excellent corrosion resistance, strength, and long-term sustainability, Stainless steel (SS) is emerging as a material of choice in modern infrastructure projects. Its low maintenance needs and high durability make it an ideal solution for demanding environments, especially in coastal, polluted, or high-humidity areas.

In infrastructure, the importance of stainless steel is no longer limited to its aesthetic appeal. It plays a structural role in the construction of bridges, buildings, transportation systems, and public utility projects. With growing concerns over the lifecycle cost of traditional and other materials, stainless steel is steadily being recognised not only for its premium quality but also for its long-term cost efficiency.

Benefits of Stainless Steel in Infrastructure Development

Stainless steel brings together durability, sustainability, and functionality, making it a perfect fit. Here is why Stainless Steel is the preferred choice of material in infrastructural projects, ranging from highways to port structures and even dams.

- Corrosion Resistance: Stainless steel is highly resistant to corrosion, making it a durable choice for infrastructure components exposed to harsh environmental conditions, such as bridges, coastal structures, and buildings in corrosive environments.

- High Strength to Weight Ratio: Stainless steel’s high tensile strength allows for optimised structural design. It helps attain optimised structural design using the least of material and without compromising on the strength criterion. It provides flexibility to the designers in being innovative while being simplistic in detailing connections, spans, and assemblies.

- Low Maintenance: Due to its resistance to corrosion, stainless steel requires minimal maintenance, reducing long-term costs and the need for frequent inspections and repairs.

- Longevity: Stainless steel has a long service life, which is essential for critical infrastructure components like bridges and structural elements. It can withstand exposure to weather, moisture, and other environmental factors for many years without significant degradation or sectional loss.

- High Strength: Stainless steel has excellent mechanical properties, including high tensile strength and the ability to withstand heavy loads. This makes it suitable for structural applications, such as supporting beams, columns, long-span girders, and shear connections.

- Aesthetic Appeal: Stainless steel’s sleek and modern appearance can enhance the visual appeal of infrastructure projects. It is often used in architectural elements, railings, facades, and decorative features to create an attractive and contemporary look.

- Fire Resistance: Certain grades of stainless steel have good fire-resistant properties, making them suitable for fire safety applications, including fire escapes and fire protection systems.

- Durability in Extreme Temperatures: Stainless steel can maintain its structural integrity in a wide range of temperatures, making it suitable for infrastructure projects in both hot and cold climates.

- Resistance to Chemical Exposure: Stainless steel is usually inert and definitely more resistant to varied chemical exposure conditions, making it an obvious choice for structures exposed to extreme chemical environments.

- Hygiene Properties: Stainless steel is easy to clean and maintains a hygienic surface, which is important in infrastructure components like public restrooms, transportation hubs, and healthcare facilities.

- Sustainability: Stainless steel is recyclable, which aligns with sustainable building practices and green infrastructure initiatives. Its long life span and the ability to reuse and recycle it reduce the environmental impact of infrastructure projects.

Grades & Types of SS Used in Infrastructure

The stainless steel grades are categorised into different categories on the basis of their chemical compositions. Each grade varies in its mechanical properties and corrosion resistance, making them suitable for a variety of applications and environments.

- Austentic Stainless Steel – The most common type of stainless steel, austenitic stainless steel contains nickel, manganese, nitrogen & sometimes molybdenum in addition to iron & chromium. These alloys cannot be hardened through heat treatment, but can be work-hardened.

- Martensitic Stainless Steel – This type of stainless steel contains carbon levels as high as 1%, allowing it to be hardened and tempered, similar to carbon and low-alloy stainless steels.

- Ferritic Stainless Steel – Ferritic stainless steel is characterised by high chromium content and low carbon content (typically less than 0.10%). They cannot be work hardened and demonstrate less formability than austenitic stainless steel. However, they offer magnetic properties, high corrosion resistance, and resistance to cracking due to corrosion.

- Duplex Stainless Steel – Duplex stainless steel features a material structure that is a combination of austenitic and ferritic phases. This quality provides them with superior strength and corrosion resistance.

- Precipitation Hardening (PH) – PH stainless steels contain additional elements, such as aluminium, copper, or niobium, and undergo heat treatments, both of which enhance their material strength. As they are less likely to experience thermal distortion, they are suitable for the manufacturing of parts with intricate designs orthose that require tight tolerances.

- Ferritic + Martensitic – There are stainless steel grades that exhibit a dual-phase microstructure containing both ferritic and martensitic characteristics. This quality provides them with superior strength, high corrosion resistance, and also offers magnetic properties.

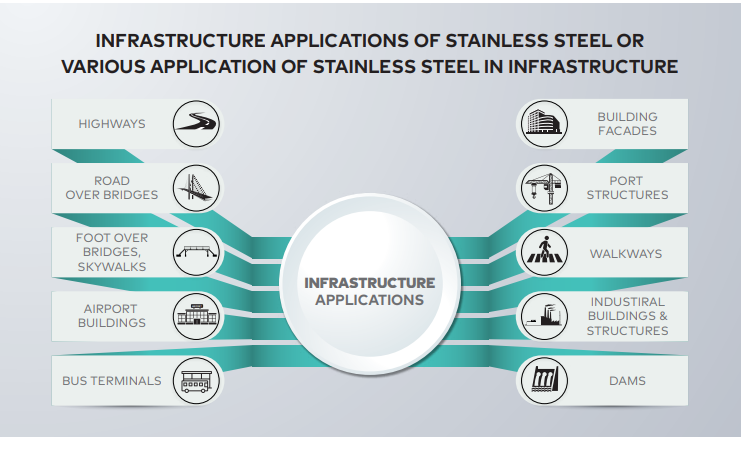

Various Applications of Stainless Steel in Infrastructure

Stainless steel has a diverse range of applications across infrastructure segments. Its usage spans from structural components to exposed architectural elements, offering both functionality and visual appeal.

1. Bridges and Flyovers

Stainless steel is used in load-bearing elements and reinforcement, such as stainless steel rebars, expansion joints, crash barriers, handrails, and claddings. In marine or saline environments, stainless steel’s resistance to corrosion makes it Ideal for bridge reinforcement, reducing the risk of premature failure.

2. Railways and Metro Infrastructure

From foot overbridges to station roofing and escalator components, stainless steel provides longevity and strength. Its use in metro rail systems helps lower maintenance costs while ensuring passenger safety and aesthetics. SS Grade IRS350CR was used in the construction of the Bhayandar FOB.

3. Water Infrastructure

Due to its corrosion resistance and hygiene, stainless steel is widely used in potable water storage tanks, pipelines, treatment plants, and drainage systems.

4. Coastal Infrastructure

In coastal regions, stainless steel proves vital in areas prone to salt spray, such as promenade railings, lighting poles, and fencing.

5. Public Furniture and Urban Architecture

From benches and bins to bus shelters and signage, stainless steel offers a modern look along with weather resistance, making it perfect for cityscapes.

Lifecycle Cost of Stainless Steel Infrastructure Solution

When it comes to large-scale infrastructure such as bridges, it is important to evaluate not just the initial construction cost but the total cost over the structure’s entire service life. This is where Life Cycle Costing (LCC) becomes a valuable tool. It offers a systematic way to assess long-term costs, including maintenance, repairs, and eventual rehabilitation.

Although stainless steel involves a higher upfront investment, typically 20 to 25 percent more than carbon steel, it offers significant savings in the long run. Its superior corrosion resistance reduces maintenance needs, fewer repairs, and extended service life.

Key benefits of stainless steel in the context of lifecycle cost include:

- Extended durability: Stainless steel structures often last twice as long as those made from carbon steel.

- Lower maintenance requirements: Minimal upkeep is required over the years, making it a practical choice for high-use infrastructure.

- Optimized weight: The high yield strength allows for a lighter design, with weight reductions of up to 30 per cent.

- Sustainability: Stainless steel is fully recyclable and supports environmentally responsible construction practices.

Key Stainless Steel Components in Infrastructure

Various stainless steel products are used in infrastructure projects depending on the function and environmental conditions. Each of these products contributes to the strength, safety, and design integrity of public infrastructure. These include:

- Stainless Steel Rebars: Used for concrete reinforcement in bridges, flyovers, coastal infrastructure, and high-load structures. They provide exceptional corrosion resistance in aggressive environments, increasing the lifespan of concrete structures. Rebars also reduce repair costs due to needing minimal maintenance.

- Plates: Employed in structural panels, load-bearing surfaces, roofing elements, and claddings. Their strength and durability make them ideal for components that demand support and resilience.

- Fabricated Structural Sections: Utilised in water transport, drainage systems, and handrail frameworks. They offer a hygienic, corrosion-resistant solution, especially crucial in water infrastructure and public safety elements.

- Fabricated Structural Sections: Used in interior paneling, roofing, signage, and aesthetic coverings.

- Welded Hollow Sections: They serve as support elements in modular and prefabricated structures. Their load-bearing capabilities and ease of fabrication make them essential in the construction of frameworks.

- Stainless Steel Chequered Plates: Ideal for anti-slip flooring, ramps, and industrial surfaces. Known for their textured finish, these plates enhance safety while maintaining durability in high-traffic environments.

Building a Resilient Future with Stainless Steel

Stainless steel is proving to be more than just a material; it’s a smart choice for lasting, low-maintenance infrastructure. Whether it’s stainless steel rebars or stainless steel plates holding up bridges or plates strengthening structural panels, its value is clear. Thinking long-term? Start with stainless steel.

Read more to know the applications of stainless steel in various infrastructural projects to make a wise decision for your next project.