A Complete Guide to Stainless Steel Chequered Sheets and Their Uses

July 11, 2025

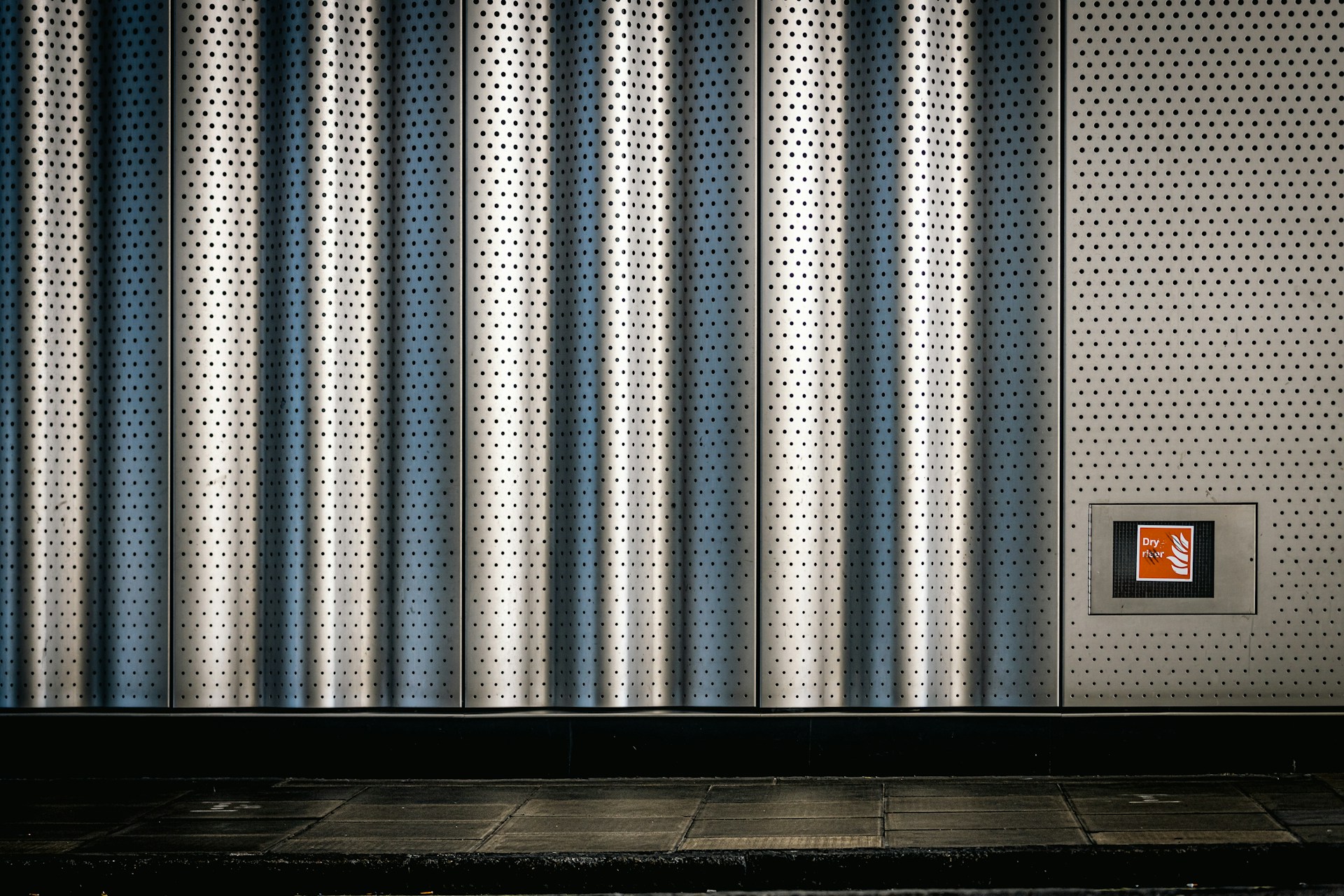

Modern construction and industrial applications demand materials that combine durability, safety, and low maintenance more than ever. Among these, stainless steel chequered sheets have emerged as a leading choice. Known for their excellent structural properties and superior performance in demanding environments, these chequered sheets are widely used in various sectors, including transportation and food processing. Their unique combination of features not only enhances operational safety but also significantly reduces lifecycle costs.

At Jindal Stainless, our chequered sheets are built to handle heavy loads while maintaining strength and stability. Their strong resistance to corrosion, wear, and environmental stress makes them well-suited for a wide range of applications, from industrial flooring to structural support.

Properties of Stainless Steel Chequered Sheets

Stainless steel chequered sheets possess a number of properties that set them apart from traditional materials:

Superior Grip and Safety:

The raised diamond or patterned surface of stainless steel chequered sheets provides excellent grip, which is important for flooring applications in both industrial and public environments.

Low Maintenance:

These chequered sheets do not require regular painting or coatings, which significantly cuts down on maintenance, labour, and material costs over time.

Extreme Durability:

Stainless steel exhibits a much lower wear rate, providing longer life and fewer replacements. It also provides heat, chemical, moisture, and corrosion resistance for tough environments like chemical plants, wastewater treatment facilities, and offshore oil platforms.

High Strength and Reliability:

These chequered sheets can withstand immense loads and pressure for long-term stability in various conditions.

Stylish and Versatile:

Chequered sheets help enhance the aesthetics of interiors, furniture, elevators, ceilings, and tiles.

Stainless Steel vs Mild Steel Chequered Sheets

Stainless steel offers significantly better corrosion resistance, providing a lifespan over 100 times longer, while mild steel requires regular painting to maintain its integrity. Its wear resistance is five times better than mild steel, reducing maintenance needs. Overall, stainless steel provides cost-effective, low-maintenance benefits with superior durability.

| Parameter | Mild Steel (IS2062) | Stainless Steel (SS 409M) | Stainless Steel Benefits |

| Corrosion resistance | Low | High | Offers over 100 times longer life in corrosive environments. |

| Yield strength | 250 MPa | 350 MPa | Enables up to 30% weight reduction using thinner yet stronger chequered sheets. |

| Wear rate | 62 | 13 | Provides 5 times better resistance to wear and abrasion. |

| Maintenance | Requires painting | No painting required | Easier upkeep with lower long-term maintenance costs. |

These characteristics reinforce the suitability of these chequered sheets for use in high-performance environments, ensuring a combination of strength, safety, and longevity.

Wide Range of Applications

Due to their combination of corrosion resistance, safety features, and aesthetic appeal, stainless steel chequered sheets are widely used in:

1. Pharmaceutical Sector

In pharmaceutical settings, chequered sheets are used in sterile and controlled environments, resisting corrosion from pharmaceutical chemicals. They also prevent damage from these chemicals and inhibit bacterial growth, making them suitable for drug production and hospital equipment.

2. Automotive Sector:

These chequered sheets provide durable and superior vehicle flooring, especially in buses, trucks, and trailers. They are designed to withstand heavy loads and constant usage, offering materials engineered for long-term durability. In high-end applications, they enhance aesthetic appeal while maintaining robustness.

3. Logistics and Transportation

Used to strengthen cargo floors, truck beds, and shipping containers, chequered sheets offer excellent load-bearing capacity and slip resistance. Their corrosion-resistant nature suits humid environments, while the anti-slip surface helps prevent goods from shifting during transport.

4. Construction

Chequered sheets transform flooring, staircases, and walkways in bridges, airports, and high-rise buildings with solutions that balance structural integrity with aesthetics. They serve as long-lasting, wear-resistant alternatives to wooden structures, ensuring safety in high-traffic areas with their anti-slip properties.

5. Manufacturing

Chequered sheets help prevent workplace accidents and contamination in chemical plants and factories, guaranteeing workplace safety. Their high resistance to chemical corrosion makes them ideal for handling hazardous fluids and extreme temperatures. They are commonly used in reactors, heat exchangers, and distillation units due to their durability under extreme conditions.

6. Food and Beverage

Chequered sheets prevent contamination through their non-reactive properties that help maintain product purity. They are ideal for use in easy-to-clean, sterile environments, such as food processing plants, breweries, and dairy facilities.

Building for the Future with Stainless Steel

With their superior performance across a range of parameters, stainless steel chequered sheets provide a practical and profitable alternative to conventional materials, such as mild steel. Their ability to combine safety, efficiency, and longevity makes them the preferred choice for industries seeking to build infrastructure that lasts, both in terms of performance and value. As the focus on lifecycle cost and sustainable solutions continues to grow, stainless steel remains the material of the future.

| Jindal Infinity’s chequered sheets don’t just comply with industry standards, they redefine them.

Jindal Stainless delivers solutions beyond the reach of conventional materials, unlocking limitless possibilities for manufacturers, suppliers, and businesses across the globe. |

For more detailed insights and specifications, download the full PDF now.