Before the desalination plant tackles water scarcity, it must survive the salt.

January 22, 2026

Desalination plants are only as efficient as the materials inside them.

Here’s how Duplex Stainless Steel can change the game.

Introduction – A Global Water Crisis

Water scarcity is a growing issue worldwide. According to the United Nations, by 2030 the global freshwater demand will exceed supply by 40%. Coastal cities, especially those in India, the Middle East, and Southeast Asia, are constantly seeking sustainable solutions to increase their freshwater supply. Desalination is expected to play a critical role in meeting the demands of such water-scarce regions.

However, desalination plants face significant challenges. The high salinity and pressurised conditions of seawater expose plants to issues like corrosion and early wear. This makes material selection crucial to ensure the long-term performance of desalination plants. Duplex Stainless Steel (DSS), offers the corrosion resistance and strength needed to meet these challenges. Let’s understand how.

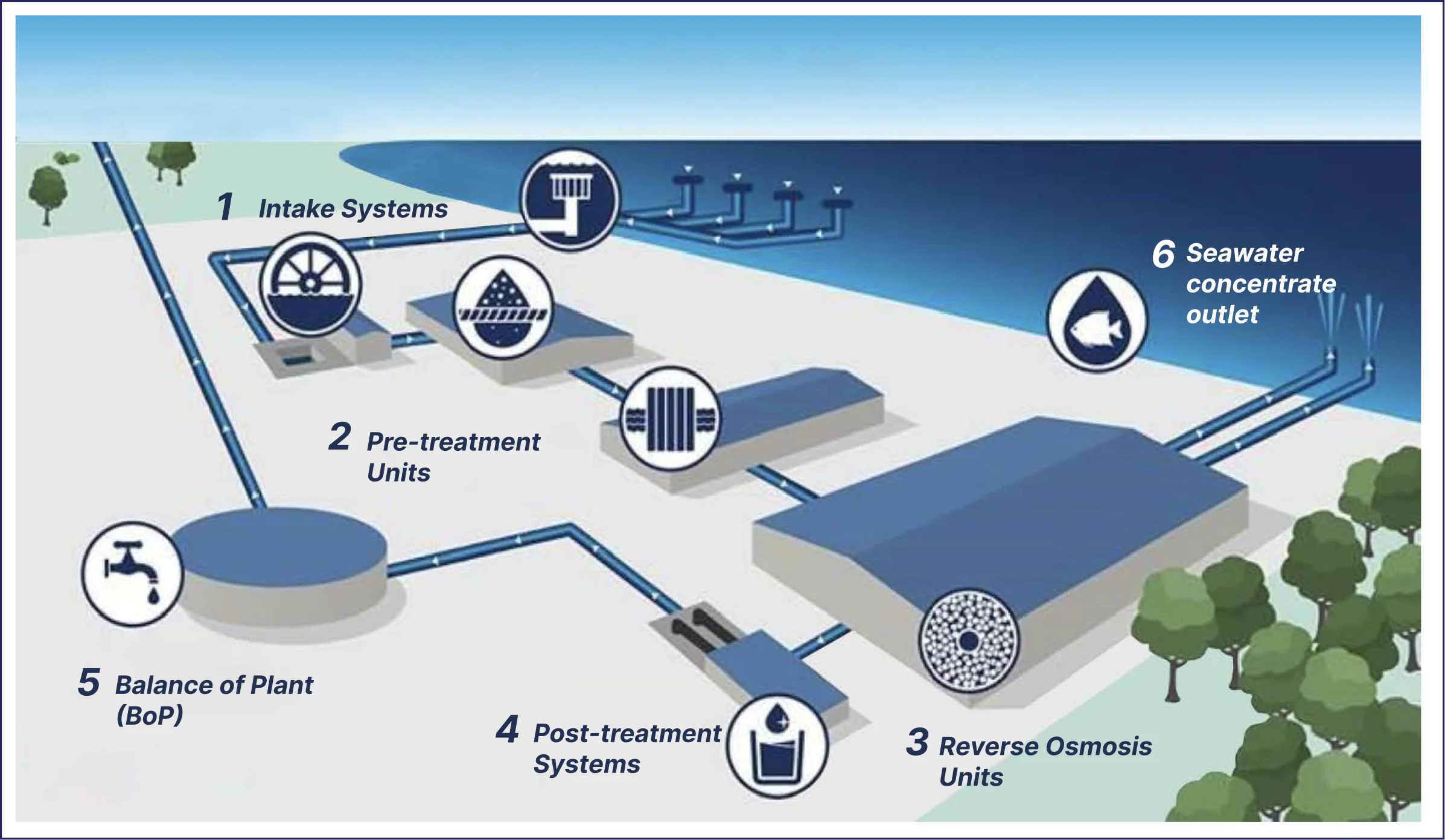

What is a Desalination Plant?

A desalination plant is a specialised facility designed to convert seawater into freshwater by removing salt and other impurities. With increasing water scarcity in coastal regions, desalination has become a vital solution for ensuring a reliable and sustainable source of clean drinking water and water for industrial or agricultural purposes.

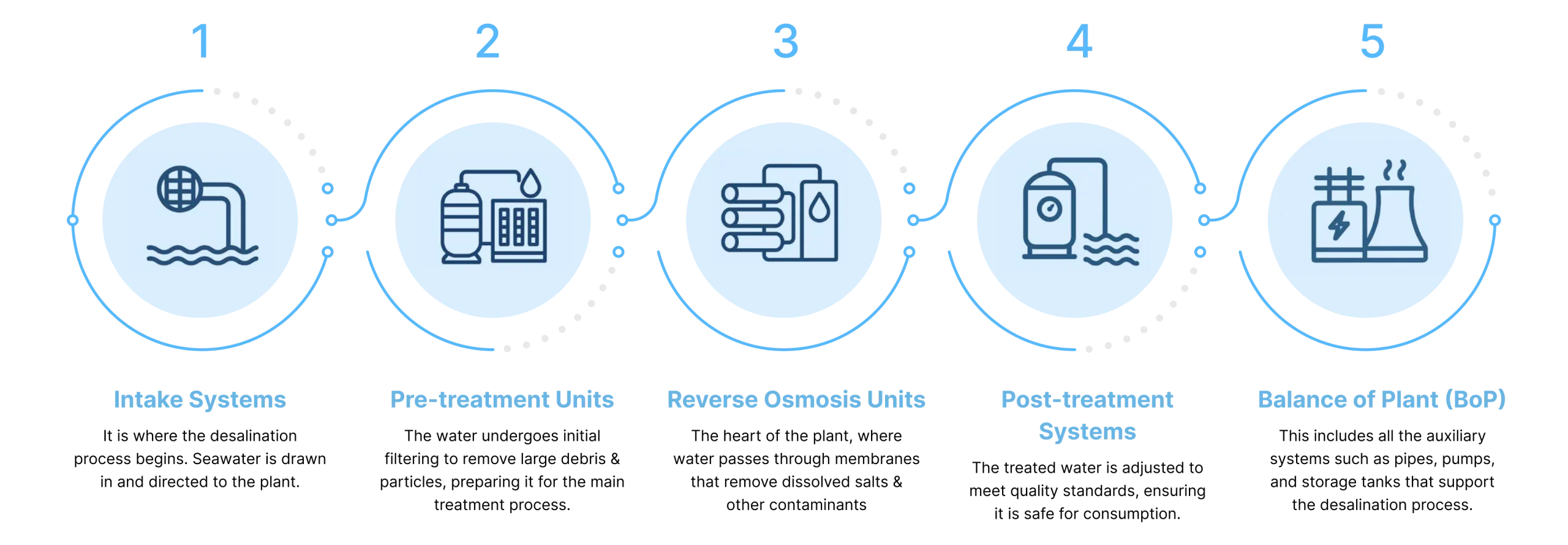

Key Areas Within a Desalination Plant

The Constant Threat

Desalination plants are exposed to some of the harshest operational environments in industrial engineering. Following tests the limits of construction materials.

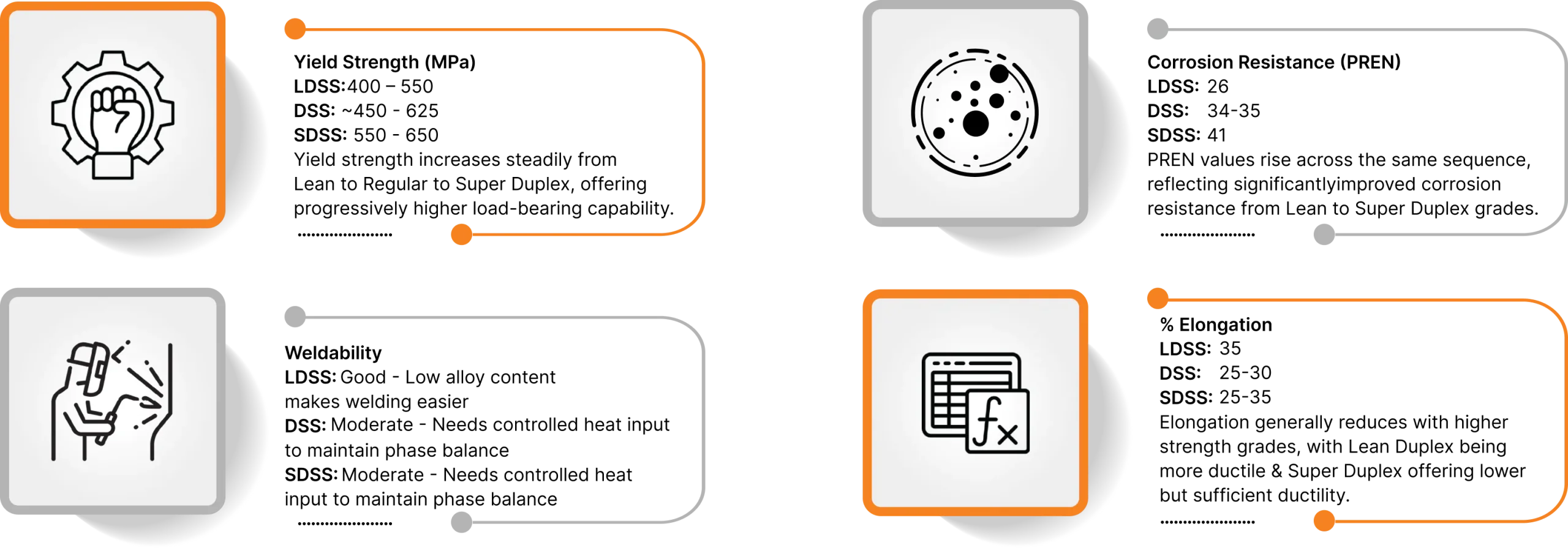

Bridging the Performance Gap in Desalination Materials

While 304-L and 316-L stainless steel is widely used in desalination plants, it struggles in highly corrosive zones such as RO reject or brine discharge lines, where pitting and crevice corrosion can appear within 6–12 months. In C5/CX corrosion environments, its service life can fall from over 15 years to just 8–10 years, undermining reliability and driving up maintenance costs.

Duplex stainless steel grades are extensively applied in corrosive environments, offering longer service life and better resilience under moderate chloride exposure. These grades are reliable for pre & post-treatment, as well as the Balance of Plant (BoP) sections.

Advantages & Value Proposition

Lean Duplex Stainless Steel (LDSS), such as S32101, bridges that gap offering high strength and corrosion resistance. For desalination operators, LDSS represents a balanced, long-term solution for sustainable and efficient water infrastructure.

JSL – India’s Leading Stainless Steel Producer

Jindal Stainless (JSL) is India’s leading producer of Duplex stainless steel, including LDSS. As a key player in the global market, JSL offers the following advantages to international clients:

![]()

Domestic Manufacturing

JSL manufactures LDSS (S32101), Standard Duplex (J2205), and Super Duplex (J2507) grades locally, which helps reduce import reliance, lower costs, and improve lead times.

Global Certifications

Global Certifications

JSL’s LDSS is recognised by international standards like ISO 21457 and ASTM, ensuring compliance with global industry requirements for desalination plants.

Proven Success

Proven Success

LDSS is already in use in desalination plants across the Middle East, Australia, Singapore, and Europe, showing its relable performance in challenging environments.

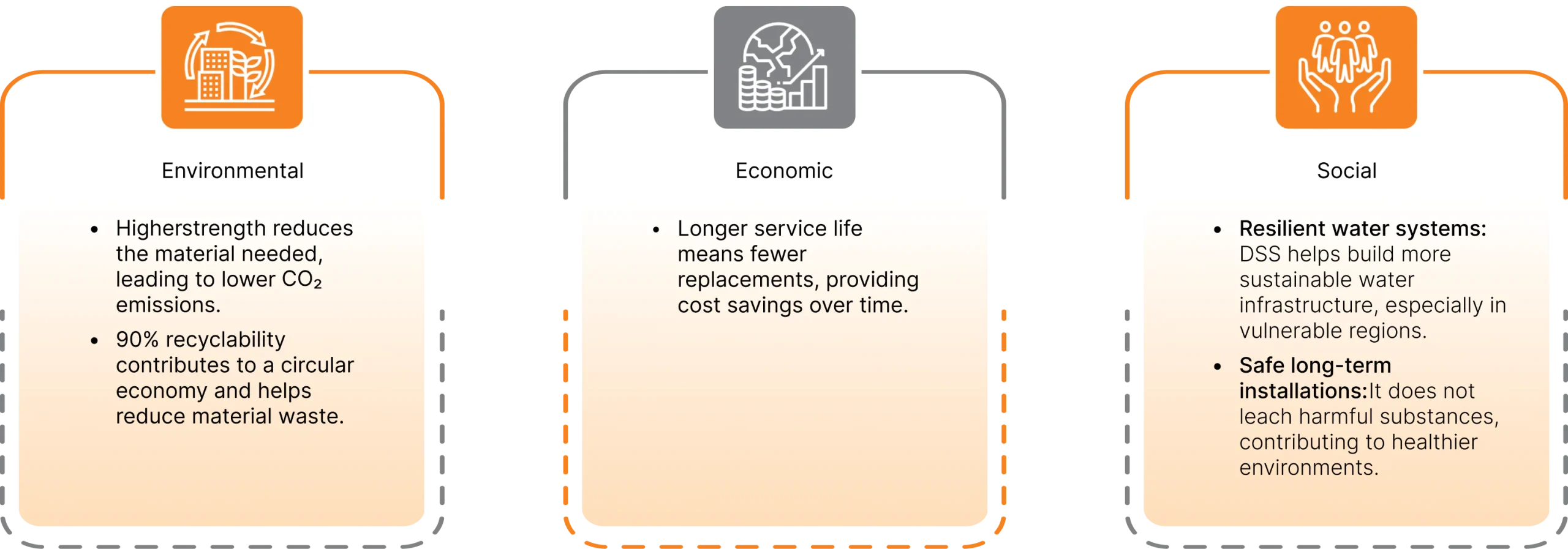

Sustainability Benefits

Smarter Stainless Steel for a Thirstier World

As desalination plant becomes an essential infrastructure for solving global water shortages, the materials used in desalination plants must meet the highest standards for strength, corrosion resistance, and affordability. Duplex stainless steel grades are the unrivalled solution for desalination plants worldwide, offering the perfect balance of performance, cost-efficiency, and long-term reliability. DSS grades developed by JSL provides global clients with a high-performance solution to the challenges of water scarcity. With superior durability, enhanced corrosion resistance, and optimised operational efficiency, JSL is equipped to meet the growing demands of the global desalination market.