Stainless Steel Angle Sizes: Standard Dimensions, Grades & Applications

September 15, 2025

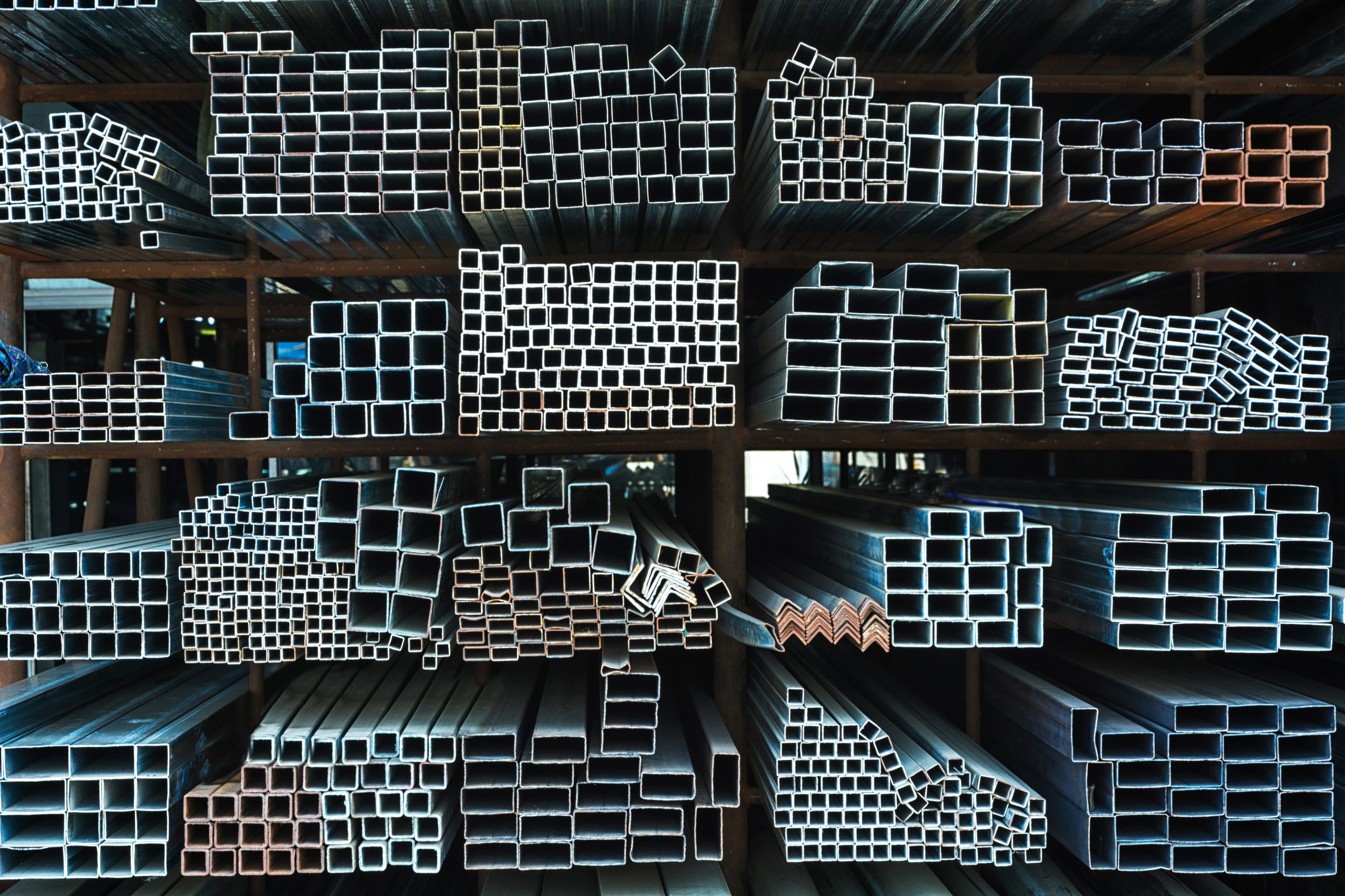

Stainless steel angles, also known as SS angles, are one of the most widely used stainless steel profiles. With their characteristic L-shaped cross-section, these angles are valued for their strength, corrosion resistance, and versatility.

Their ability to balance durability, design flexibility, and low maintenance makes them an irreplaceable material choice in modern engineering and construction. But with so many sizes and grades available, how do you choose the right one? Let’s break it down one by one.

What is a Stainless Steel Angle

A stainless steel angle (SS angle) is a profile shaped like the letter “L”, designed to give structural support in areas where two surfaces meet. They’re commonly seen in frameworks, reinforcements, and support systems where stability and resistance to environmental damage are needed.

There are two primary types:

- Equal Angle: Both legs are of equal length. These are widely used when balanced strength is required on both sides, such as in beams, frames, and columns.

- Unequal Angle: one leg is longer than the other, making them useful in applications where loads are not evenly distributed or where design constraints require varied support.

SS angles are manufactured in different forms depending on the method of production:

- Hot-rolled angles: Produced at high temperatures, these are stronger and ideal for heavy-duty structural applications, such as bridges and large buildings.

- Cold-formed angles: Manufactured at room temperature, these offer precise dimensions, cleaner finishes, and are popular in fabrication, decorative work, and lighter structures.

Standard Stainless Steel Angle Dimensions

One of the advantages of SS angles is their availability in a wide range of dimensions, making them adaptable to everything from delicate designs to large-scale infrastructure.

Typical size ranges include:

- Thickness: 3mm to 20mm

- Leg Width: 20mm to 200mm

- Length: Standard 6 meters

Equal vs Unequal Sizes – Example

| Type | Common Sizes (mm) | Thickness (mm) | Length (m) |

| Equal Angle | 25 x 25, 50 x 50, 100 x 100 | 3–12 | 6 |

| Unequal Angle | 40 x 20, 100 x 50, 150 x 75 | 3–12 | 6 |

Grades of Stainless Steel Angles

- 304 stainless steel:

This is the most widely used grade of stainless steel. Known for its excellent balance of strength and corrosion resistance, 304 is suitable for both indoor and outdoor use. It is often found in railings, frameworks, and general fabrication work, making it the go-to choice for everyday construction needs.

- 316 stainless steel:

With the addition of molybdenum, 316 stainless steel offers superior resistance to chlorides, chemicals, and acids. This makes it particularly valuable in marine environments, chemical plants, and coastal structures, where exposure to salt and harsh substances is unavoidable.

- 202 stainless steel:

As a more economical alternative to 304 and 316, grade 202 provides good strength and moderate corrosion resistance. While it may not match higher grades in demanding environments, it is well-suited for decorative work, furniture, and indoor applications, where affordability and appearance matter most.

- Duplex stainless steel:

Combining the properties of both austenitic and ferritic stainless steels, duplex grades deliver exceptional strength and resistance to stress corrosion cracking. This makes them ideal for oil & gas, desalination, and offshore projects, where performance under extreme conditions is critical.

Applications of SS Angles

- Construction and infrastructure: Used in bridges, towers, transmission lines, and building frameworks where load-bearing capacity is critical.

- Industrial machinery and equipment: Provide structural stability in machine frames, conveyor supports, and manufacturing setups.

- Shipbuilding and marine uses: Resist saltwater corrosion, making them ideal for docks, ship components, and marine hardware.

- Decorative and architectural purposes: From modern staircases to interior trims, SS angles are valued for strength and polished looks.

Benefits of Using Stainless Steel Angles

High strength-to-weight ratio

Although lightweight compared to bulkier alternatives, stainless steel offers excellent structural support. This makes them ideal for applications that demand stability and efficiency, such as frameworks, bridges, and high-rise buildings.

Superior corrosion resistance

Stainless steel’s natural resistance to corrosion and oxidation is one of its biggest strengths. In coastal areas, chemical plants, or humid climates, stainless steel angles perform consistently without the degradation seen in mild steel. This resistance ensures that structures remain safe and reliable even in harsh conditions.

Long lifespan and low maintenance

Choosing stainless steel angles means reducing the frequency of repairs or replacement. Once installed, they require little maintenance, resulting in significant savings over the project’s life cycle. For industries where downtime is costly, this reliability is a huge advantage.

Design Versatility

Stainless steel angles are highly adaptable. They can be cut, welded, bent, polished, or fabricated to meet specific requirements, whether functional or decorative. This flexibility makes them equally suited to industrial machinery, modern interiors, and architectural detailing.

The Right Angle for Every Application

Stainless steel angles stand out for their strength, corrosion resistance, and adaptability. With a wide range of sizes and grades, they support everything from heavy infrastructure to sleek architectural finishes. Selecting the right grade ensures durability in any environment, making SS angles not just structural components but a dependable investment in long-term performance.