Monthly

Stainless Trivia

Fill in your answer below

Company to support kitchenware industry’s growth in Eastern India; pegged at around 7%

Kolkata, January 5, 2019: Jindal Stainless, India’s largest stainless steel manufacturing group, has expanded its stainless steel footprint in the kitchenware segment to cater to the demand from eastern India. Considering the current high growth rate and immense diversification potential of this metal in the country, Jindal Stainless is taking bold measures to expand its presence in this segment, and increase its supply to small and medium‐sized enterprises in eastern India. As kitchenware segment is adopting a more organized format after the introduction of GST, the opportunities in this segment have grown manifold. Speaking to the media on the sidelines of the 9th Indian Stainless Steel Houseware Show organized in Kolkata, Head, Sales, Jindal Stainless, Mr Vijay Sharma said, “We pioneered extensive growth of this segment by introducing the 200 series (Chrome Manganese) of utensil‐grade stainless steel for domestic consumption and exports. Now, we are making deeper inroads in eastern India by adopting a three‐pronged approach; capitalizing the coil route in manufacturing, increased, dedicated capacities at our associate facility, and facilitating growth for downstream industries in eastern India. With this, we will raise the overall quality standards in the industry, and thereby grow the contribution to state exchequer through greater GST compliance.”

In line with the ‘Make in India’ mission of the Government of India, Jindal Stainless, with its associate company, has planned installation of additional 2 lakh tonnes/annum cold rolled production capacity at its Jajpur facility, which will greatly contribute to this segment. This development is further motivated by the aim to minimize transport costs for eastern India’s demand, thereby increasing cost competitiveness of stainless steel over its sub‐optimal alternatives. Of the major application segments of stainless steel in India, the kitchenware industry takes a lion’s share of 40‐45%. The end‐products comprise tableware, cookware, cutlery, gas stoves, sinks, and similar applications. While the national annual growth rate for this segment is pegged at 7%, it has grown at about 4% in eastern India, namely, West Bengal, Odisha, Bihar, Jharkhand, and the eight north‐eastern states.

Considering that eastern India has not witnessed downstream expansion of stainless steel, availability of the metal remains a challenge. The region therefore continues to use alternatives to stainless steel such as aluminium and plastics, reflecting the immense growth potential for stainless steel. With the onset of enhanced capacities, downstream industries in this region are expected to flourish. Jindal Stainless is set to replicate this phenomenon in the kitchenware segment, as it did in the case of the pipe and tube industry when its Jajpur facility became operational. As Jindal Stainless’ Jajpur plant increases its coil production for kitchenware segment, associated downstream processing units are expected to emerge in eastern and north‐eastern India with an expected additional consumption of 1 lakh tonne per annum in next 2‐3 years. Jindal Stainless will extend support to these industries by way of special incentives & schemes, and guided handholding.

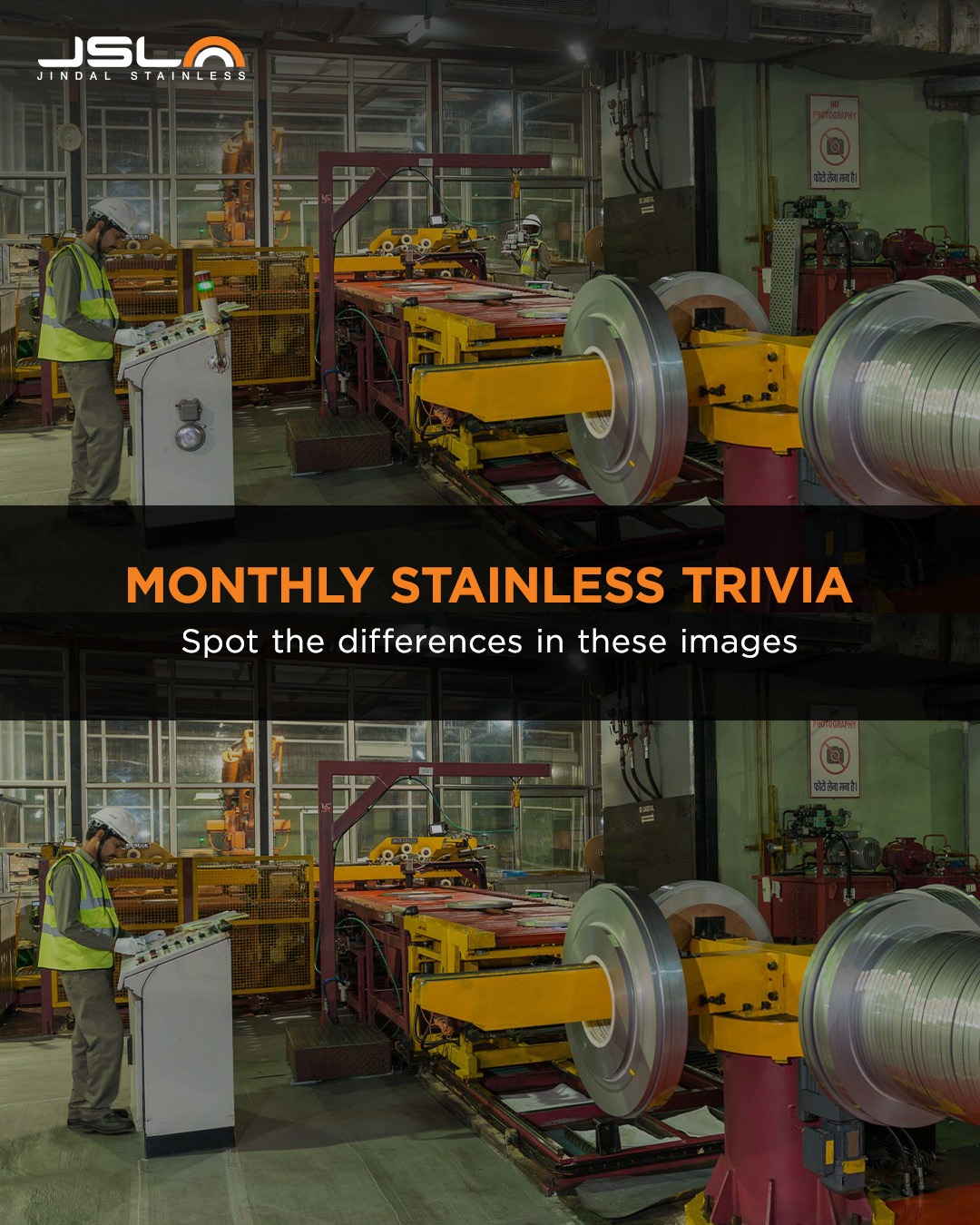

Jindal Stainless will reinforce automation of processes in this segment for manufacturing utensil‐ grade stainless steel coils. As compared to the traditional and manual patta route, coils allow for better yield efficiency and high productivity through reduced wastage. Adopting this route eventually translates into cost reduction and improved product consistency, both of which are hard to attain manually. Globally, stainless steel is preferred over its major competitor, aluminium, for the kitchenware industry, as stainless steel is inherently hygienic, durable, corrosion‐resistant, and is certified for food safety. In India, This industry has grown to be at par with other industries in the post‐GST era. The finished products in this segment continue to earn large export capital for India. As per the current market trend, stainless steel’s competitiveness in this segment is impaired by a glut of cheaper imports from China and ASEAN countries.