How Do We Build Stronger Hydro-Structures And A Safer Future

A closer look at what's weakening our water lifelines and the breakthrough materials that promise strength, longevity, and safety.

Introduction To India’s Silent Force

What powers our cities, tames our rivers and quenches our thirst? What lies behind the towering walls of our dams and the roaring turbines of our hydropower plants? And what happens when these silent pillars of progress face an invisible, relentless enemy? In this blog, lets uncover answers to these questions.

India’s Hydro-Structures: Strong On The Surface, Vulnerable Within

India stands as the world's third-largest dam builder, with an impressive number of 5,300 functional large dams. Among these, more than 1,100 have crossed 50 years in age, and some surpassing 120 years. While these structures are celebrated as engineering marvels, their ageing is not the only concern. Beneath their solid exteriors lies a growing danger, one that doesn't discriminate between old and new projects: corrosion.

Corrosion: A Threat To India’s Hydro-Structures

Corrosion poses a serious threat to both decades-old structures and newly built projects across India.

The cost of corrosion is estimated at a staggering $137.9 billion, accounting for nearly 4% of the GDP.

ITO Barrage, Delhi

ITO Barrage, Delhi

Issue: 5/32 Gates Jammed

Impact: Delhi faced Flood

Reason: Corrosion, Irregular Maintenance

Farakka Barrage, West Bengal

Farakka Barrage, West Bengal

Issue: All Gates Corroded

Impact: Repair & Rehabilitation

Reason: Corrosion, Irregular Maintenance

Kopili Dam, Assam

Kopili Dam, Assam

Issue: Penstock Burst

Impact: 4 persons went missing

Reason: High Sulphur content in water leading to corrosion

Why Corrosion Needs Immediate Action

Structural Integrity at Risk

Corrosion weakens metal and concrete components, turning sturdy structures into fragile liabilities.

Operational Disruptions

Corroded equipment leads to breakdowns, delays, and costly repairs.

Economic Consequences

Maintenance and unplanned repairs drain financial resources.

Environmental Hazards

Leaks, failures, and potential flooding pose serious risks to ecosystems and nearby communities.

This photograph, taken at a dam in Gujarat, shows the stark difference between mild steel and stainless steel in identical environmental conditions. The SS electrical box, installed in 2013, remains intact, while the recently painted MS chequered plate from 2019 is corroded. A clear evidence of stainless steel’s superior longevity and corrosion resistance in hydro environments.

What Makes Hydro-Structures Last

As India continues its journey of hydro-infrastructure development, both for upgrading existing structures and constructing new ones, it becomes critical to understand what really makes a dam resilient. Is it the concrete that holds back the river's currents, or the gates that control its flow? The answer lies in the materials that stand against nature's tests.

This is where stainless steel emerges as an indispensable material in modern dam construction. From gates to spillways, stainless steel has been proven to enhance the overall durability of hydro-structures.

This photograph, taken at a dam in Gujarat, shows the stark difference between mild steel and stainless steel in identical environmental conditions. The SS electrical box, installed in 2013, remains intact, while the recently painted MS chequered plate from 2019 is corroded. A clear evidence of stainless steel’s superior longevity and corrosion resistance in hydro environments.

Stainless Steel Solutions And Where They Matter

Jindal Stainless offers a diverse range of products, from LDSS to high-strength rebars and chequered plates, tailored to meet modern infrastructural needs. These products not only provide longevity but transform the way construction and maintenance of critical infrastructure is approached.

| Sr No. | SS Products | Application in Dam Structures |

|---|---|---|

| 1 | Lean Duplex Stainless Steel (LDSS) | Dam gates, spillways, hydro-mechanical structures |

| 2 | Stainless Steel Rebars | Structural reinforcements, flood barriers, concrete supports |

| 3 | Stainless Steel Chequered Plates | Walkways, platforms, staircases, maintenance pathways |

-

The Strength Of Lean Duplex Stainless Steel (LDSS) For Mighty Dam Gates

Dam gates are constantly exposed to high water pressure, sediment erosion, and corrosive environments. For such critical structures, longevity and reliability are paramount. Lean Duplex Stainless Steel (LDSS) delivers both. With its unique combination of austenite and ferrite structures, it ensures a balanced combination of strength and corrosion resistance. Unlike conventional carbon steel, LDSS withstands extreme hydraulic forces without jamming or failure, ensuring smooth water regulation and a significantly longer service life.

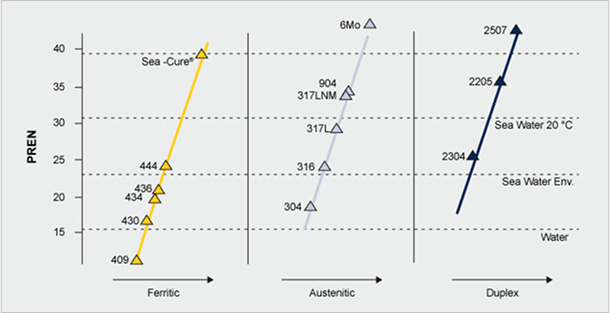

*PREN Chart

Features

- Twice the Yield Strength: With twice yield strength LDSS ensures dam gates withstand immense hydraulic pressures with ease.

- Significant Weight Reduction: Up to 35% reduced weight as per IS4623 and IS4622 which means lighter structures and simpler logistics.

- Superior Corrosion and Erosion Resistance: With a PREN* of 25 or more, LDSS significantly reduces corrosion-related degradation, ensuring longevity in both freshwater and aggressive environments.

- Long-Term Cost Savings: Over a 50-year timeframe, LDSS can provide savings of up to 3 to 3.75 times compared to traditional materials, factoring in costs related to raw material, fabrication, erection, repair, and maintenance.

-

Stainless Steel (SS) Rebars For Long Lasting Dams And Barrages

Concrete may shape a dam, but its true strength comes from within. Traditional carbon steel rebars, though commonly used, corrode in high-moisture environments, causing cracks, structural weakening, and other risks that no hydro project can afford. SS rebars eliminate this vulnerability with superior corrosion resistance and strength retention. They ensure long-term durability and minimal maintenance, even in coastal or chemically aggressive conditions. Given the challenges of repairing submerged structures, investing in SS rebars from the start is a strategic investment in the longevity and safety of hydro projects.

Superior Corrosion Resistance

Highly resistant to corrosion, ideal for harsh environments such as coastal and high-altitude regions.

Higher Strength and Ductility

Withstands high loads and seismic stresses, improving structural resilience.

Crack Prevention

Minimizes the risk of concrete cracking, ensuring long-term integrity.

Reduced Lifecycle Cost

Up to 50% savings by minimizing repairs, downtime, and associated disruption costs.

-

SS Chequered Plates For Safe And Efficient HydroStructures

In dam construction, structural materials take priority, while safety-focused components like flooring are often overlooked. Yet, in hydro environments where water exposure, slippery surfaces pose high risks, the right flooring can mean the difference between seamless operations and hazardous conditions.

Stainless steel (SS) chequered plates outperform mild steel by offering built-in corrosion resistance and lasting durability. Additionally, it eliminates the need for frequent replacements or repainting. Their high wear resistance, lightweight properties, and ability to drain water efficiently make them the ideal flooring solution for walkways, platforms, staircases, and maintenance zones within hydro structures. By cutting maintenance costs, extending service life, and improving worker safety, SS chequered plates turn an overlooked component into a strategic asset in hydro projects.

Slip Resistant Surface

SS Chequered plates provide superior grip, reducing the risk of slips and falls in wet and high-traffic areas.

Exceptional Wear Resistance

These plates exhibit wear resistance up to 5X greater than conventional materials, providing longer service life even under continuous mechanical stress.

Lifecycle Cost Efficiency

Up to 50% lower lifecycle cost than those of traditional materials, thanks to reduced maintenance needs and extended durability.

Lightweight and Malleable

With a weight reduction of 15-20% and improved malleability, these plates are easier to handle and install.

The Ultimate Choice For Resilient And Low Maintenance Infrastructure

The consistent issues and failures of past infrastructure projects have made it clear that compromising on materials comes at a high cost. As our country prepares to meet growing water and energy demands, the materials we choose today will define the resilience of our infrastructure tomorrow.

Therefore, investing in high-performance materials like Stainless Steel is the key to building a smarter, stronger, and safer future. Its superior strength, corrosion resistance, and extended lifespan can significantly reduce maintenance burdens and extend the life of dams, barrages, and pump storage gates.

But time is of the essence. The question is no longer whether we should act, but how soon.