Monthly

Stainless Trivia

Fill in your answer below

JINDAL INFINITY INFRASTRUCTURE SOLUTIONS

Advisory

Grade Selection, Approvals, Policy Framework Support, Adhering & Developing Standards, Training, Design and more

Raw Material Supplier

Stainless Steel Plate, Stainless Steel Reinforcement Bars, Stainless Steel Chequered Plate

Customization

Cutting, Slitting, Fabrication, Welding, Drilling

Fabricated Components

Girders, Facade, Railing, Bus Shelter, Built-up Sections, Angle & Channels

RECOMMENDED FASTENERS DETAILS FOR FABRICATION OF JINDAL INFINITY

| Item | Code | Grade |

|---|---|---|

| Bolt | ASTM A193 | GR B8 Class 2 |

| Nut | ASTM A194 | GR 8 |

| Washer | Type 303 |

All types of nuts & bolts domestically available

Visit www.makestainless.com for suppliers of consumables, fasteners and fabricated components.

Weldability of Jindal Infinity

It is recommended to use ER308L, ER309L, ER316L, and their higher silicon content counterparts, however ER309L has by far been the most widely used filler wire for welding of the plate girders fabricated with Jindal Infinity. Suitable flux should be used with filler wires. For FCAW, ER 309L and for GMAW – ER 309L/ER 309LMo with Gas mixture Ar-98% are recommended. However, any other suitable welding consumable permissible by AWS D1.6 may also be used

LCC Analysis

- A. Initial cost increase is 20-25% over existing carbon steel

- B. Low maintenance over carbon steel. For aesthetics purpose, Paint is recommended for utility Ferritic stainless steel. Addresses the current challenges of maintaining bridges like safety, accessability, shutdowns, additional costfor upkeeping and channelizing dedicated resources for the repeat jobs.

- C. Weight Reduction of more than 25-30% achieved due to higher Yield Strength and light weight design

- D. Payback period is less than 20 years

- E. Stainless steel is green material and helps in reducing Carbon Foot Print

- F. Service life of stainless steel is more than 100 years

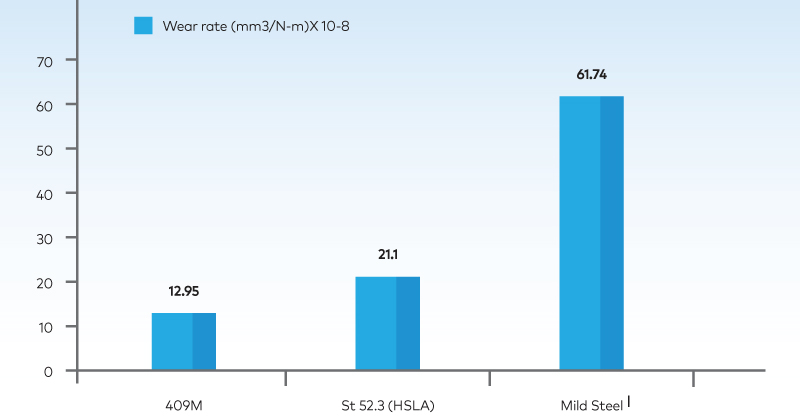

UP TO 5 TIMES HIGHER WEAR RESISTANCE FOR HIGHER COST SAVINGS

Grade 409M is known for its high wear resistance. Under the sliding wear test condition grade 409M is 1.6 times better than HSLA steel and 4.7 times better than normal mild steel.

INNOVATED FOR A STRONG & LONG-LASTING FUTURE

PRODUCT RANGE

THE PROMISE OF PROGRESS

STRENGTHENED BY SAFER AND RELIABLE

Railway Bridge Pathway: Ensuring safety & convenience during maintenance and inspections.

JINDAL STAINLESS CHEQUERED SHEETS

Architectural Stairs & Flooring with a lustrous finish and high aesthetic appeal

THE PERFECT BLEND OF STRENGTH & DURABILITY TO COMPLEMENT PROGRESS

INTRODUCING JINDAL INFITY REBARS

Chemical Composition of SS Rebar Grade G (410 L) as per IS 16651:2017:

| Chemical | C | Ni | Mn | Si | P | S | Cr | N |

|---|---|---|---|---|---|---|---|---|

| Min % | 11 | - | ||||||

| Max % | 0.03 | 0.6 | 1 | 1 | 0.04 | 0.03 | 13.5 | - |

Mechanical Properties of High Strength Deformed Stainless Steel Bars and Wires as per IS 16651:2017:

| S. No. | Properties | SS 500 | SS 550 | SS 600 | SS 650 |

|---|---|---|---|---|---|

| 1 | 0.2 percent proof stress (Rp0.2), Min, N/mm2 | 500 | 550 | 600 | 650 |

| 2 | Percentage elongation after fracture (A5), Min, on gauge length 5.65 √A, where A is the cross-sectional area of the test piece | 16 | 14.5 | 10 | 10 |

Product Offering:

| Diameter (mm) | 8 mm to 32 mm |

|---|---|

| Standard Length | 12 mtrs. |

Policy from Ministry of Road Transport and Highways:

Use of Stainless Steel Rebars in Bridges on National Highways and other centrally sponsored Projects to be constructed in marine Environment Susceptible to Severe Corrosion

STAINLESS STEEL FOOT-OVER BRIDGE

BHAYANDAR RAILWAY STATION, MUMBAI DIVISION, WESTERN RAILWAY

Project Details

| Project | Bhayandar FOB, Western Railway |

|---|---|

| Contrator | Sai Projects Mumbai Pvt Ltd., Mumbai |

| Fabricator | Sai Projects Mumbai Pvt Ltd., Mumbai |

| Stainless Steel Supplier | Jindal Stainless Ltd. |

Stainless Steel used in Project

| Grade | Product | Application | Quantity (MT) |

|---|---|---|---|

| IRS350CR | HRAP Plates/Sheets (6mm to 40mm thickness) | Girders / Columns/ Hollow Sections | 170 |

STAINLESS STEEL FOOT-OVER BRIDGE

SRIKAKULAM ROAD RAILWAY STATION, WALTAIR DIVISION, EAST COAST RAILWAY

Project Details

| Project | Srikakulam FOB, Waltair Division, East Coast Railway |

|---|---|

| Contrator | MD Jahageer, Visakhapatnam |

| Fabricator | Pennar Industries Ltd, Hyderabad |

| Stainless Steel Supplier | Jindal Stainless Ltd. |

Stainless Steel used in Project

| Grade | Product | Application | Quantity (MT) |

|---|---|---|---|

| X2CrNi12 | HRAP Plates/Sheets (6mm to 40mm thickness) | Girders / Columns/ Hollow Sections | 182 |

| X2CrNi12 | HRAP Chequered sheets (3.5mm & 4mm thickness) | Roof deck Sheet | 18 |

| IRS350CR | CRAP Sheets (2mm thickness | Walkway side protective sheeting | 5 |