How Indian Railways Took a Step Towards a Stronger, Safer Future with Jindal Infinity Stainless Steel Chequered Plates

Railway bridges are vital arteries of transportation. Not only do they carry millions of passengers but also

tonnes of freight across long distances. However, history has witnessed unfortunate incidents where unsafe

infrastructure has led to accidents and tragic loss of lives.

Ever wondered how to ensure their safety and longevity? It takes thorough inspection and maintenance of

every single component, including non-structural elements and effective inspections are only possible when

inspectors have reliable support systems to access every part of a bridge. One such element is a well-laid

set of chequered plates, which form the foundation of safe

walkways, gangways, and

trolley refuges.

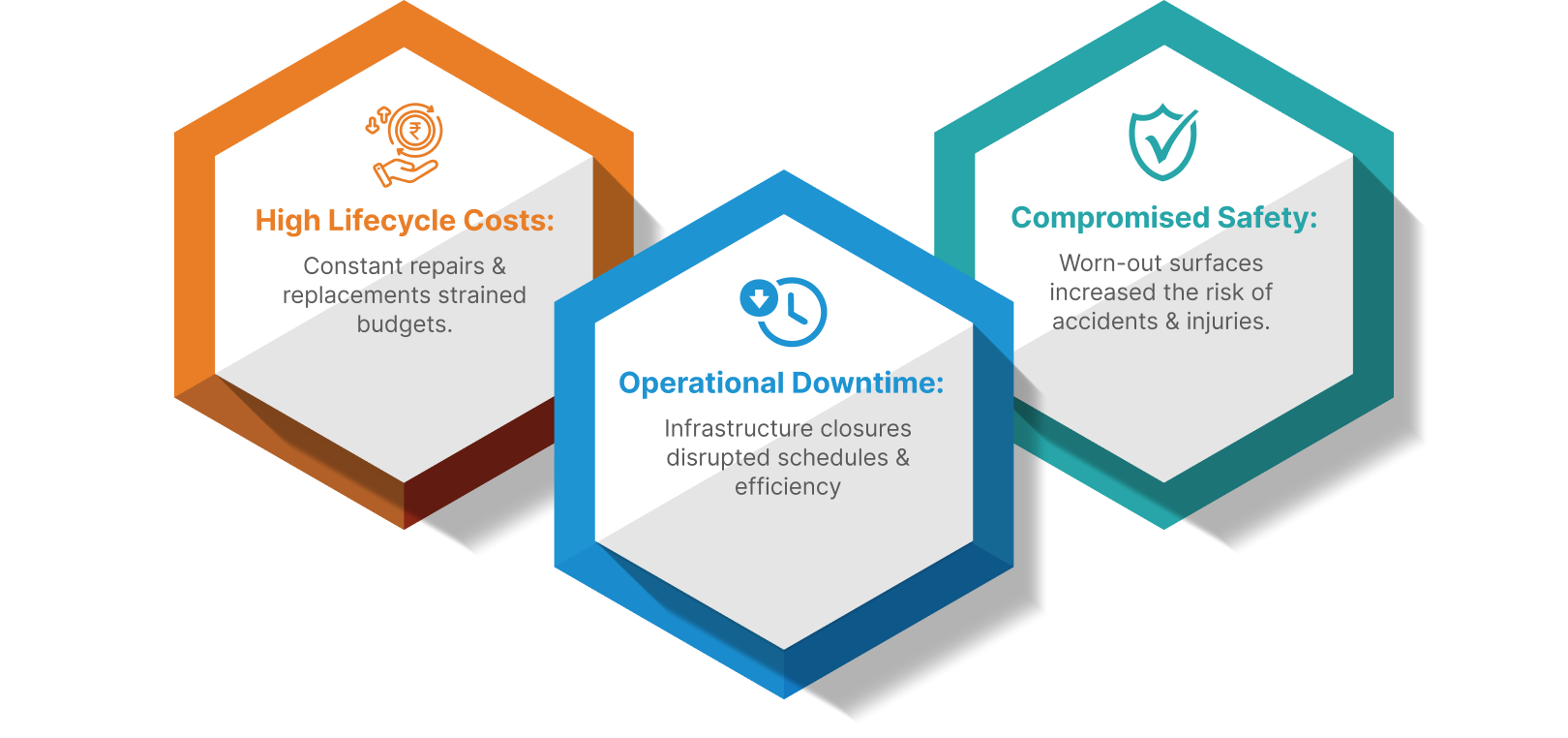

The Challenge

For years, Indian Railways faced a persistent challenge of maintaining its bridge flooring safe and durable. The traditional mild steel (MS) chequered plates used on railway bridges were highly prone to corrosion, leading to frequent replacements, high maintenance costs, and safety risks. The need for a more resilient solution was pressing. Their existing flooring solutions led to:

The Solution

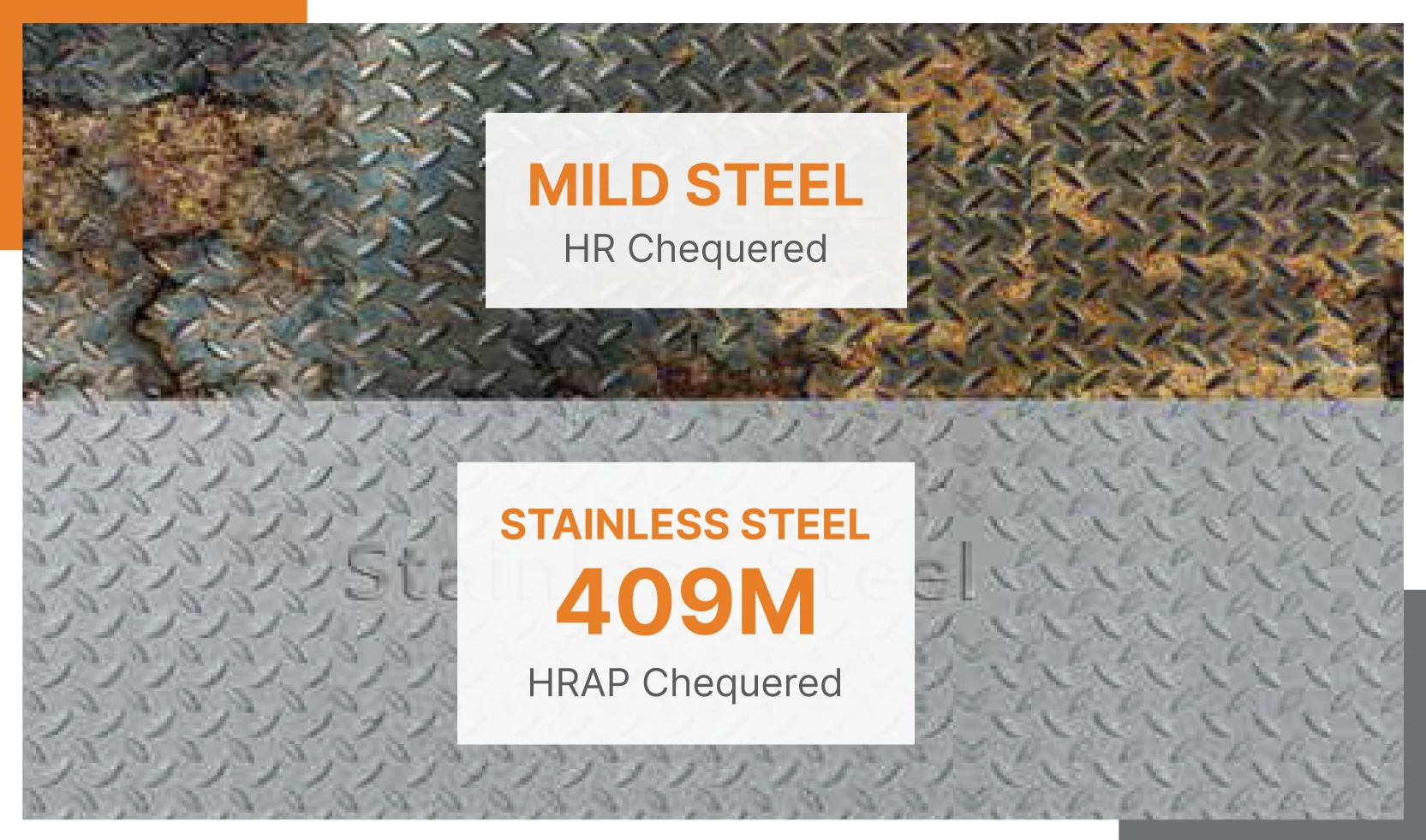

Recognizing this critical issue, Jindal Stainless introduced an innovative solution: Jindal Infinity Chequered Plates (409M), a high-performing alternative to traditional Mild Steel chequered plates over a 25-year life cycle. Designed to withstand harsh conditions with minimal upkeep, these plates promised enhanced durability, safety, and cost savings—transforming the way Indian Railways approached bridge maintenance.

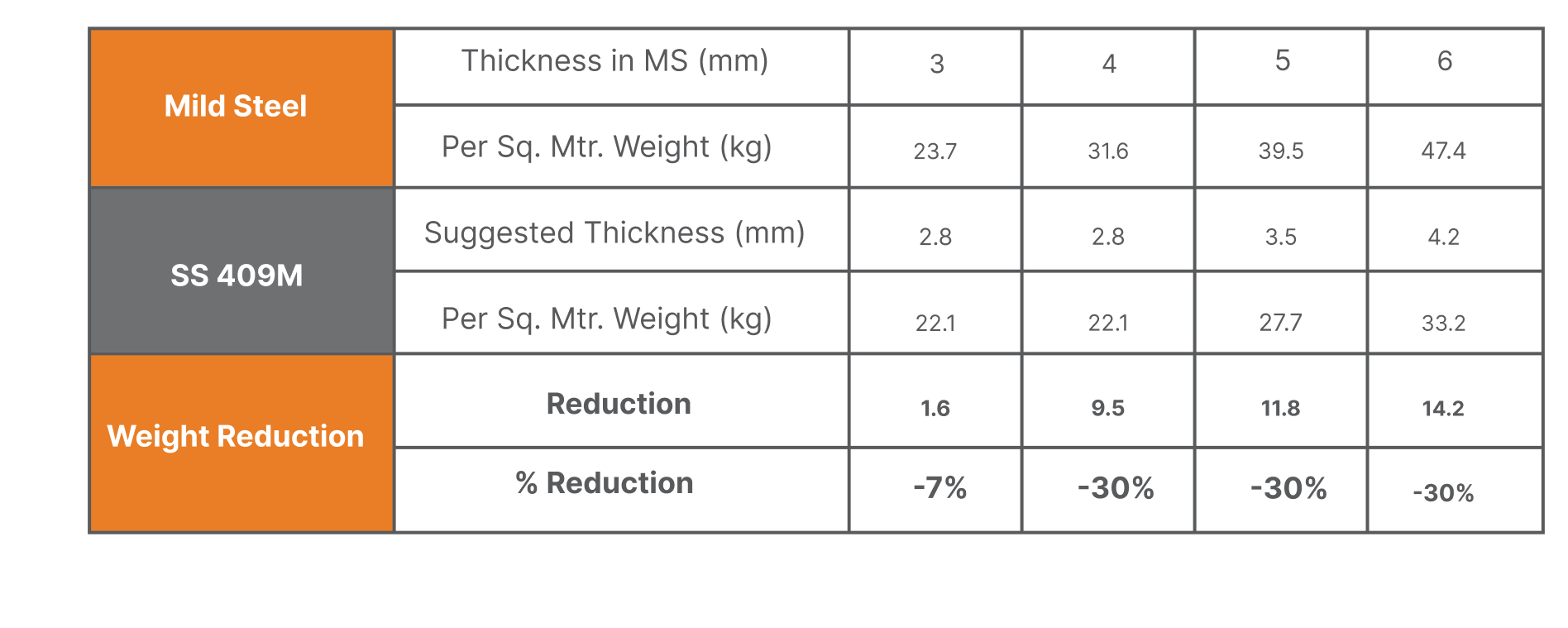

30% Lighter Weight With Higher Durability

.png)

The Key Advantages

The Key Advantages

.png)

Jindal Infinity Chequered Plates: Product Specifications and Features

Pattern Specifications:

Jindal Infinity Chequered Plates have been expertly engineered from 409M grade stainless steel to tackle the key issues of corrosion, sustainability, and operational efficiency. Designed to resemble IS 3502 Pattern 1A standards, they feature dimensions of 27 mm in length, 8 mm in width, and a bead height varying between 0.70 mm and 1.10 mm.

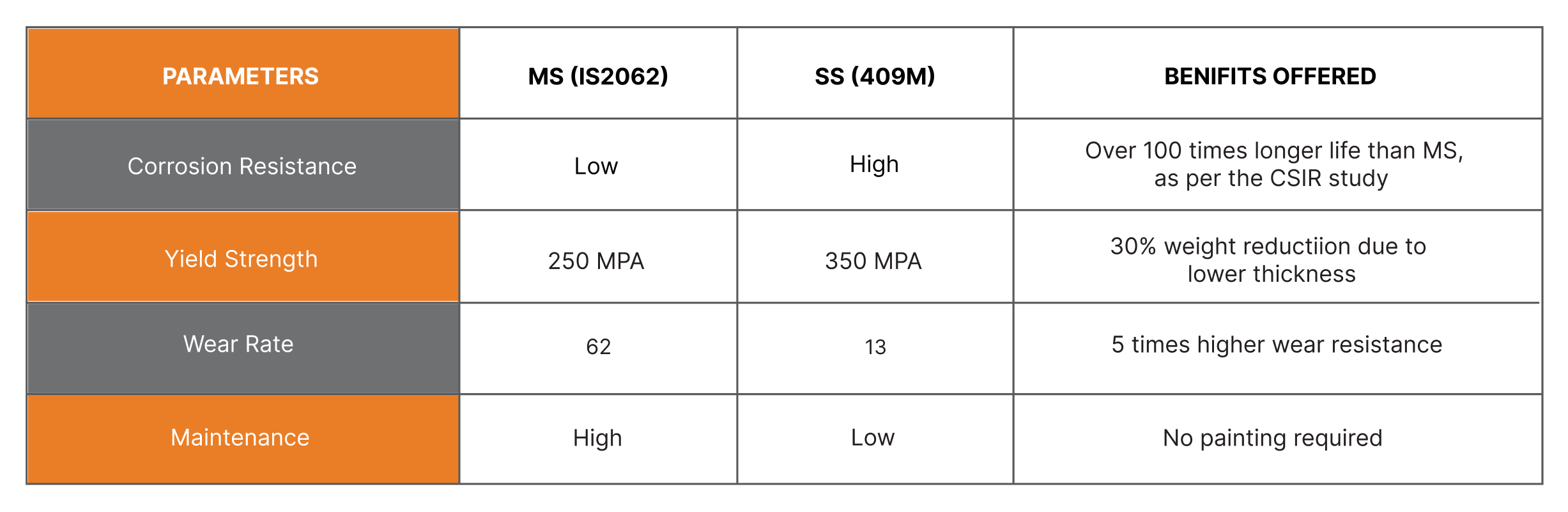

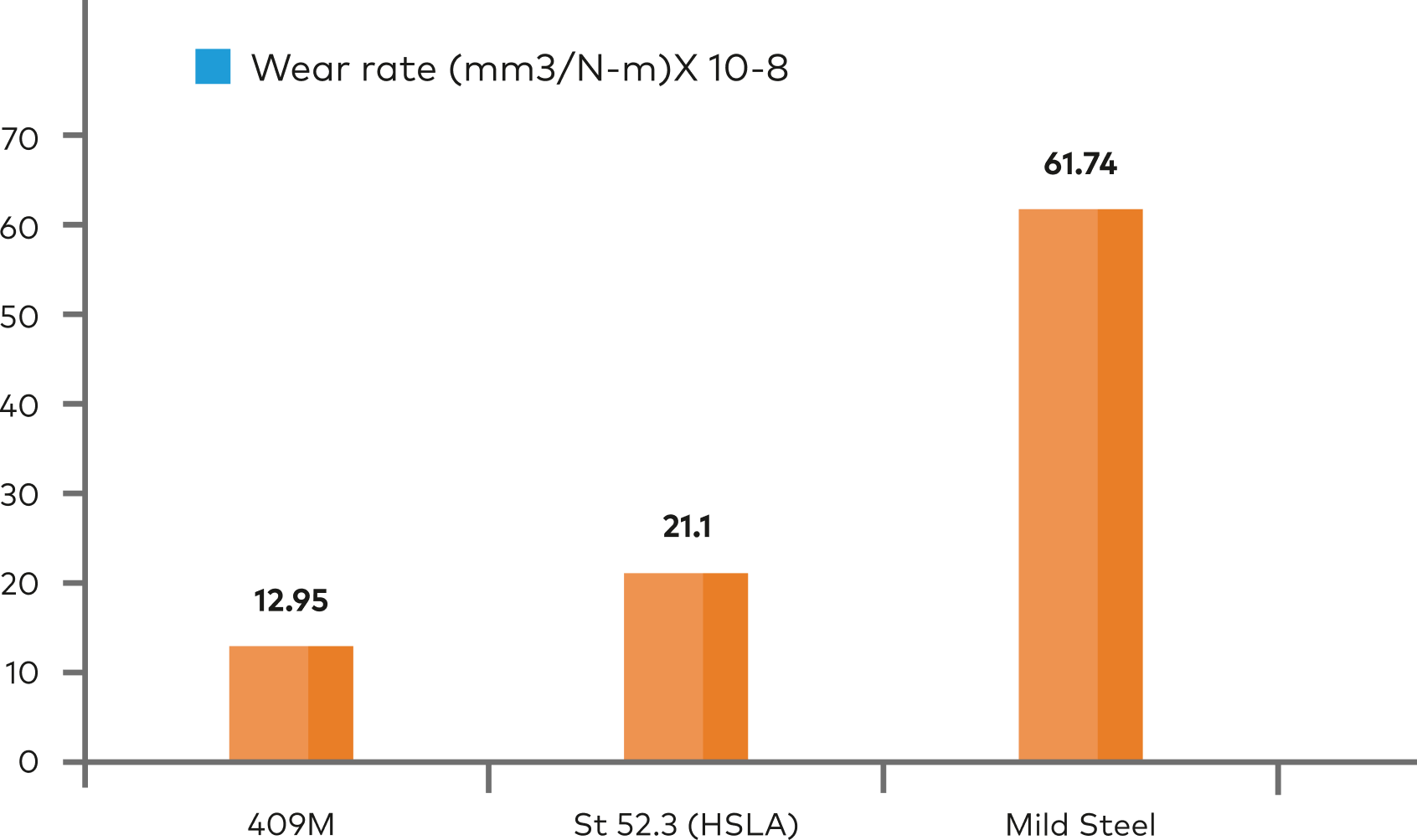

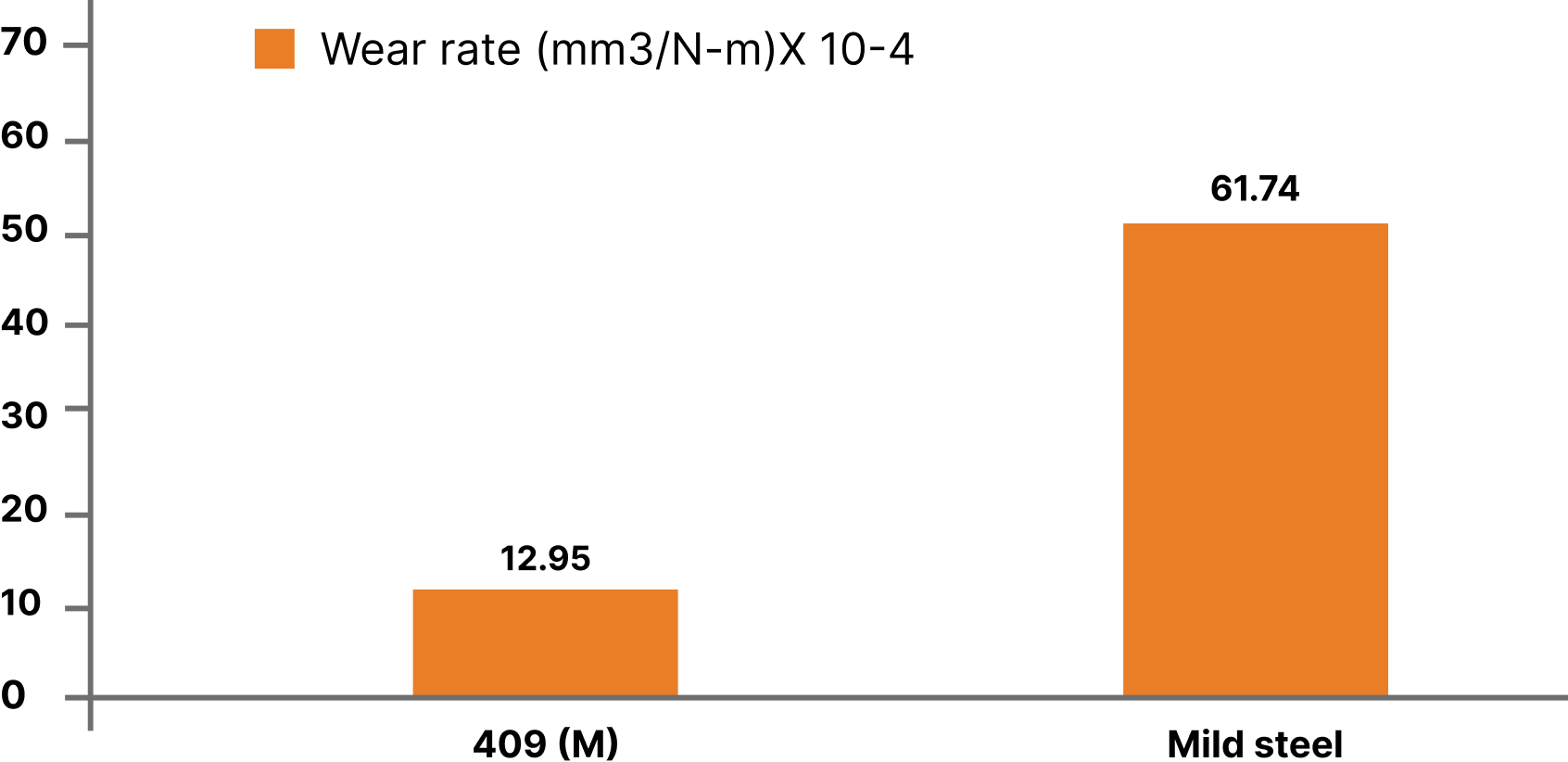

Wear Resistance

4.7X

With 4.7 times better wear resistance as compared to traditional mild steel, 409M stainless steel offers extended lifespan and substantial reductions in maintenance costs.

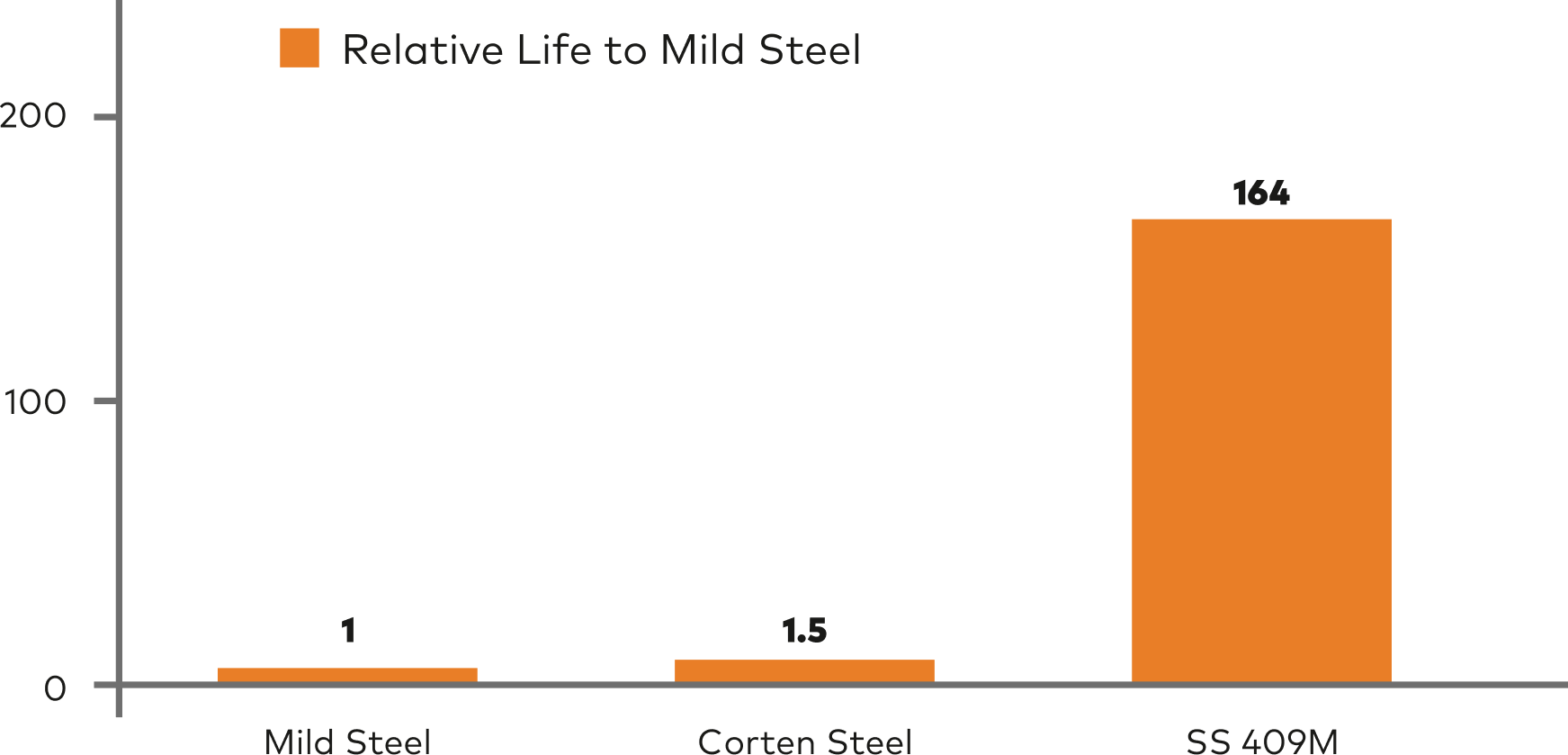

Corrosion Resistance

164X

Better corrosion resistance than mild steel, 409M stainless steel ensures durability in harsh environments while reducing disruptions and enhancing safety.

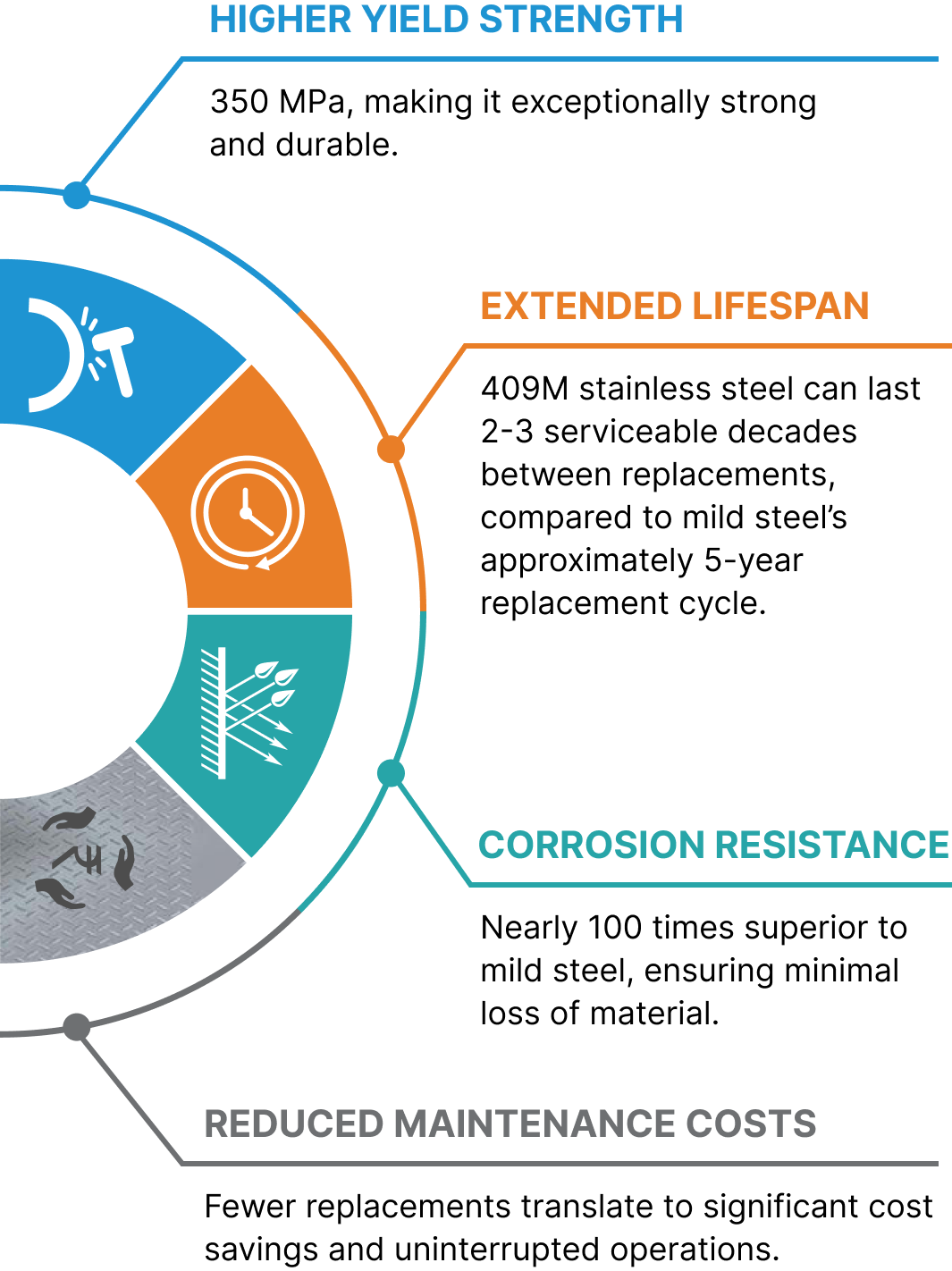

Higher Yield Strength and Skid Resistance

With a higher yield strength of 350 MPa and superior skid resistance, these plates not only protect structural stability but also optimize overall operational efficiency, perfectly meeting the rigorous demands of modern railway systems.

Sliding Wear Resistance Performance

- 409 (M) is 4.76 times better than Mild steel

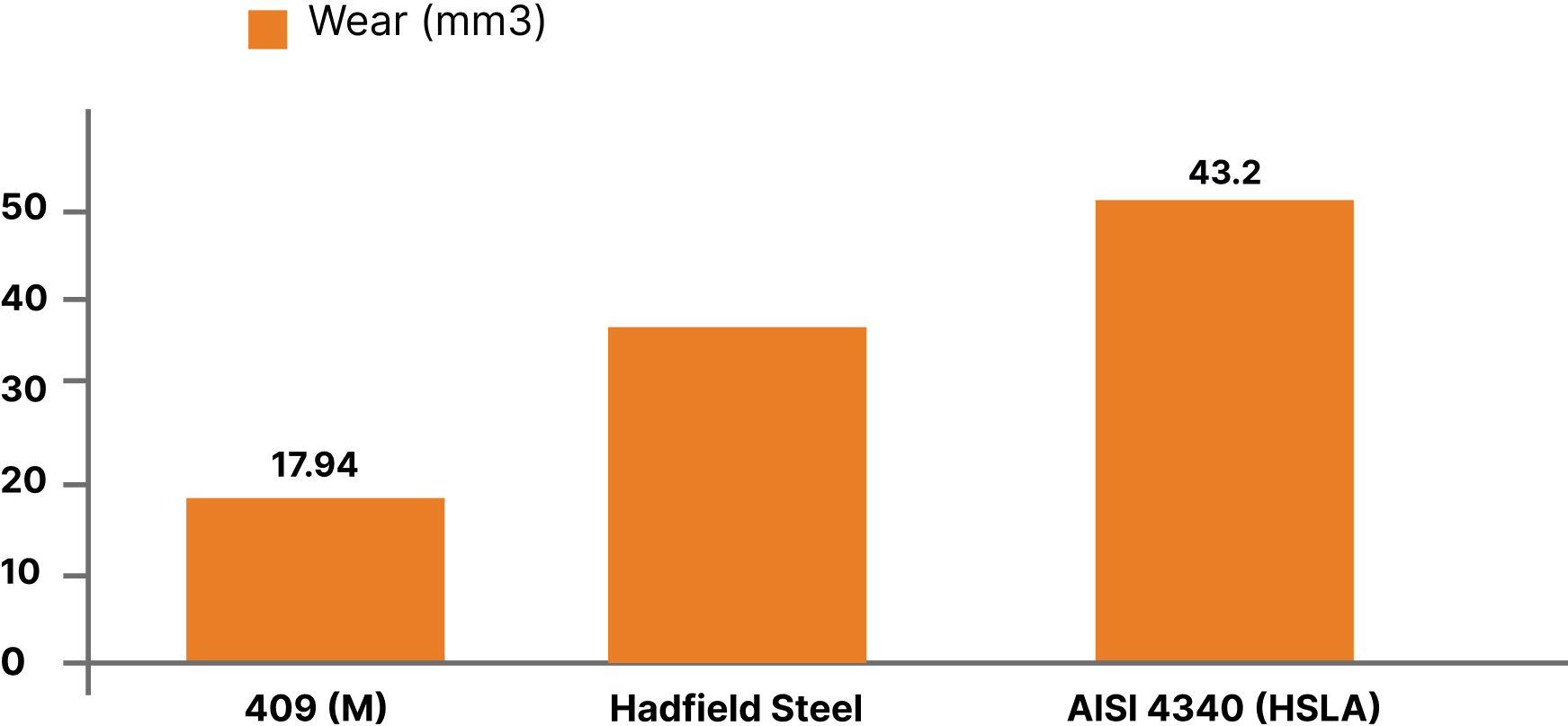

Abrasive Wear Resistance In Wet Condition

- 409 (M) is 2.06 times better than hadfield steel

- 409 (M) is 2.41 times better than HSLA steel

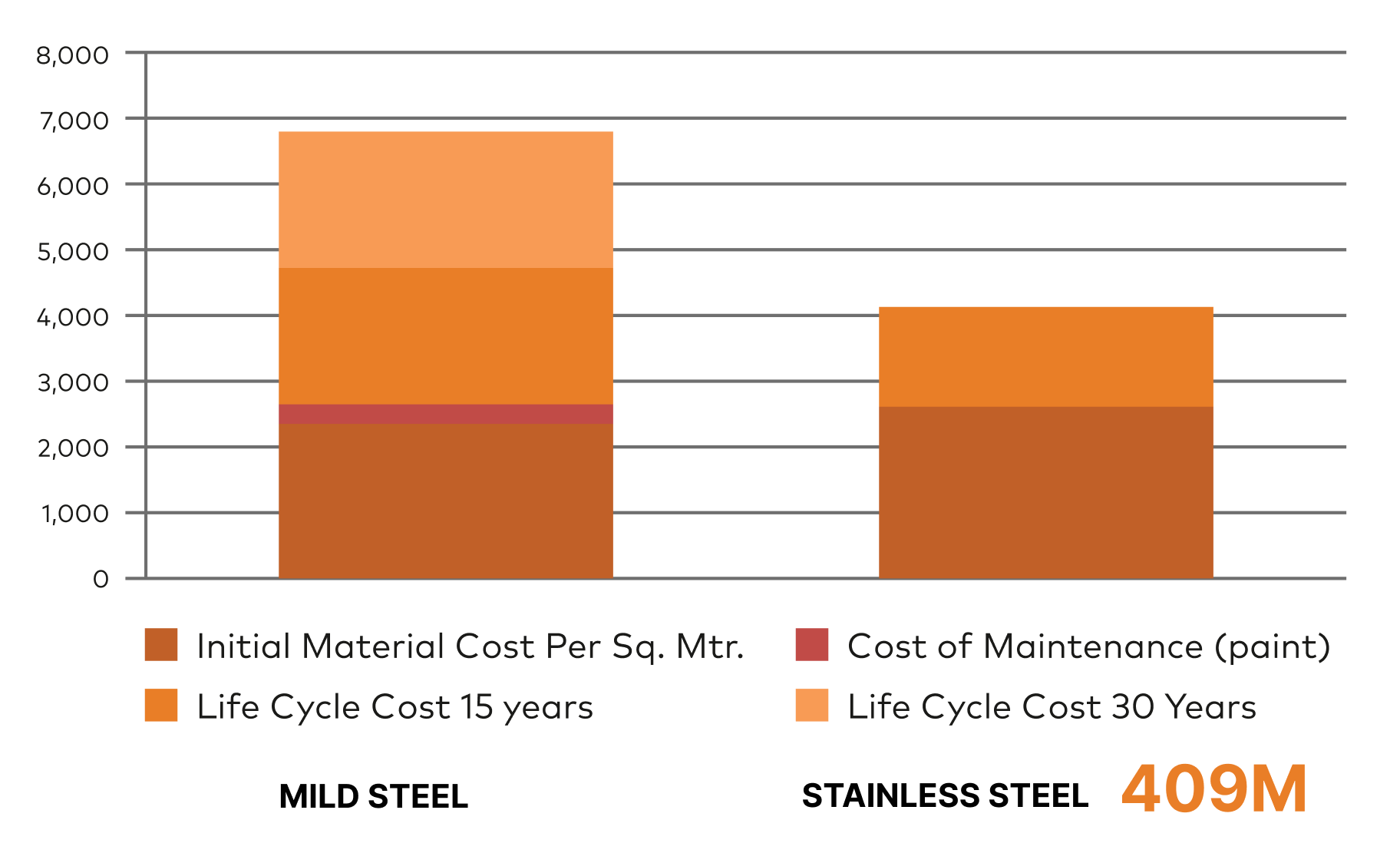

Life Cycle Cost Analysis: Stainless Steel (409M) vs. Mild Steel (Over 30 Years)

While mild steel may need replacement every 5 years, 409M stainless steel lasts 20–30 years, cutting down maintenance costs and minimizing downtime. With 100x better corrosion resistance, 4.7x higher wear resistance, and a 350 MPa yield strength, Jindal Infinity Chequered Plates ensure long-term savings, superior performance, and a future-ready railway system. These are an investment in durability and efficiency.