Monthly

Stainless Trivia

Fill in your answer below

READY-TO-STRIKE COIN BLANKS

A coin blank is a metal disc ready for striking. The blank is punched in its round form from a metal strip, and then processed through a rimming machine, which raises the edge rims on the blank and turns it into a coin blank.

Mono Metal Blanks

These are punched out from a solid metal strip of copper, copper alloy or stainless steel.

Copper Based Alloys

These are made from metal alloys based on copper. Alloying elements can be nickel, tin, aluminium, etc. Alloying means mixing two or more metals. Base metals are over 50% of the alloy.

Bi-Metal Blanks

These are produced from two different metals that normally have different colours. Bi-metal blanks can be produced from steel blanks and copper alloy blanks as well as from two different colour copper alloys.

OFFERED SERVICES

Jindal Stainless Limited offers technical assistance to mints for them achieve an excellent end-product.

Advice on design to complement existing series, alterations, and renewals along with the introduction of new coins and coin series.

Development of ideas in the form of new coin denominations.

Sampling of coinage alloys.

INFRASTRUCTURAL EXCELLENCE

Testing Equipment

- Optical Emission

- Spectrometer

- XRF machines

- Electron microscopes

- Tensile & hardness tester

- Surface roughness tester

- Profile Projectors

Mechanical Testing

- Preparing samples

- Tensile tests

- Elasticity tests

- Elongation tests

- Hardness tests

- Bending yield limit

Chemical Laboratory

- Chemical composition of raw material

- Controlling production processes (casting, rolling, annealing, cleaning, finishing, etc.)

- Checking quality finished products

THE MOST POPULAR ALLOYS

| COINAGE MATERIALS | DIN DESIGNATION | MAIN ELEMENTS | DENSITY Kg/dm 3 |

VICKERS HARDNESS |

|---|---|---|---|---|

| Cupronickel 25 | CuNi 25 | Cu 75%, Ni 25% | 8.9 | 80 |

| Nickel silver 20 | CuNi20Zn15 | Cu 65%, Ni 20%, Zn 15% | 8.7 | 85 |

| Nickel silver 18 | CuNi18Zn20 | Cu 62%, Ni 18%, Zn 20% | 8.7 | 85 |

| Nickel silver 15 | CuNi15Zn25 | Cu 60%, Ni 15%, Zn 25% | 8.7 | 85 |

| Nickel silver 12 | CuNi12Zn24 | Cu 64%, Ni 12%, Zn 24% | 8.7 | 85 |

| Nickel silver 9 | CuNi9Zn10 | Cu 81%, Ni 9%, Zn 10% | 8.75 | 70 |

| Nickel silver 6 | CuNi5.5Zn24.5 | Cu 70%, Ni 5.5%, Zn 24.5% | 8.7 | 85 |

| Brass 70/30 | CuZn30 | Cu 70%, Zn 30% | 8.5 | 75 |

| Brass 64/36 | CuZn36 | Cu 64%, Zn 36% | 8.4 | 85 |

| Nickel-brass -5 | CuZn20Ni | Cu 75%, Zn 20%, Ni 5% | 8.7 | 70 |

| Nickel-brass -1 | CuZn20Ni | Cu 75%, Zn 20%, Ni 5% | 8.7 | 70 |

| Aluminium-Nickel-Bronze 6 | CuA1Ni2 | Cu 92%, A1 6%, Ni 2% | 8.1 | 85 |

| Ferritic SS- AISI430 | X8Cr17 | Fe 83%, Cr 17% | 7.7 | 160 |

BI-METAL BLANKS COMBINATION

| EXTERNAL RINGS | |

|---|---|

| Stainless steel AISI 430 | White |

| Cupronickel type CuNi25 | White |

| Cupronickel type CuNi25 | White |

| Bronze type CuAI6Ni2 | Golden |

| Bronze type CuAI6Ni2 | Golden |

| Bronze type CuZn2.5Sn0.5 | Reddish |

| INSERTS | |

|---|---|

| Bronze type CuAI6Ni2 | Golden |

| Bronze type CuAI6Ni2 | Golden |

| Cupronickel type CuNi25 | White |

| Bronze type CuZn2.5Sn0.5 | Reddish |

| Bronze type CuZn2.5Sn0.5 | Reddish |

| Bronze type CuAI6Ni2 | Golden |

PRODUCT DETAILS: COIN BLANKS

| THICKNESS RANGE | 12 TO 30 MM |

| THICKNESS RANGE | 0.85 TO 2.5 MM |

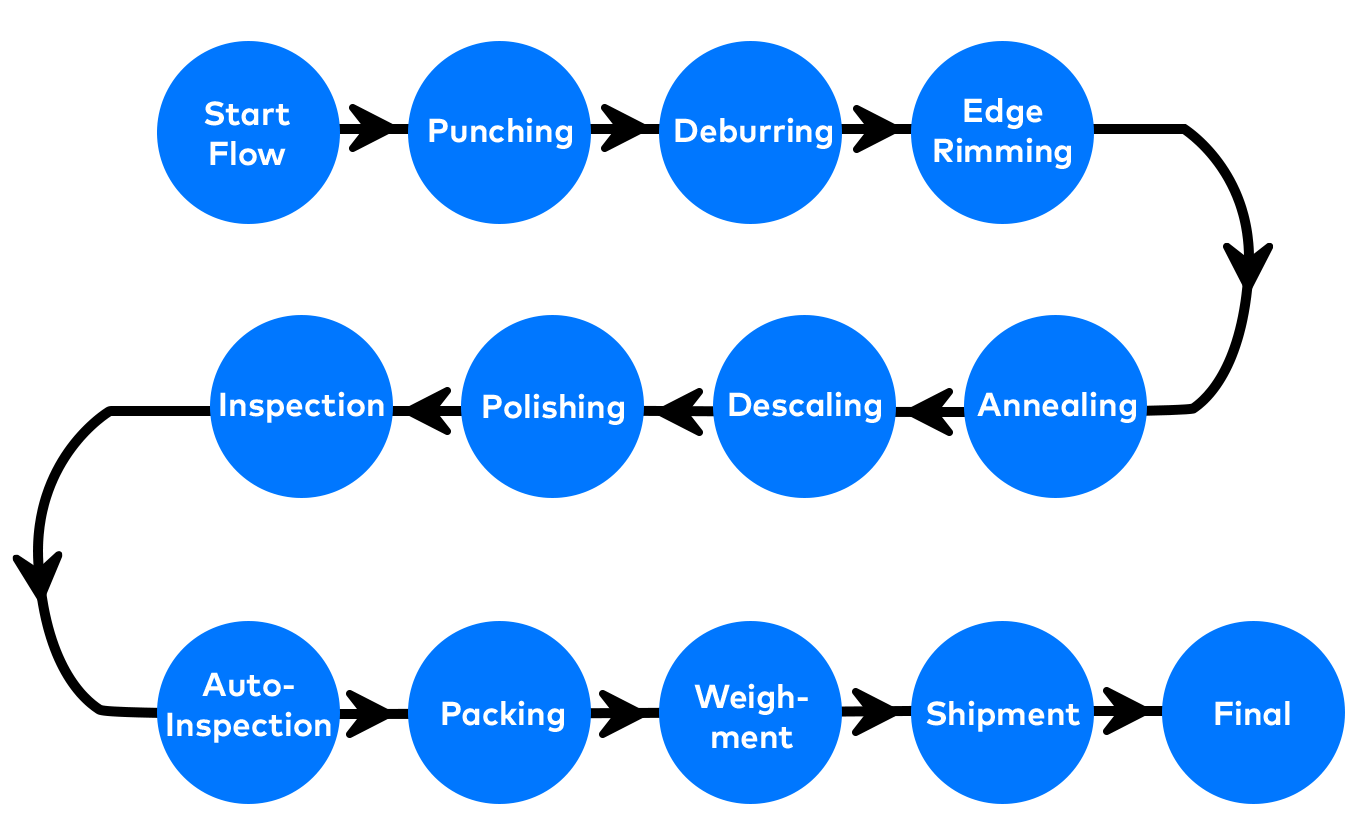

PROCESS FLOW DIAGRAM

FOR COIN BLANKS: