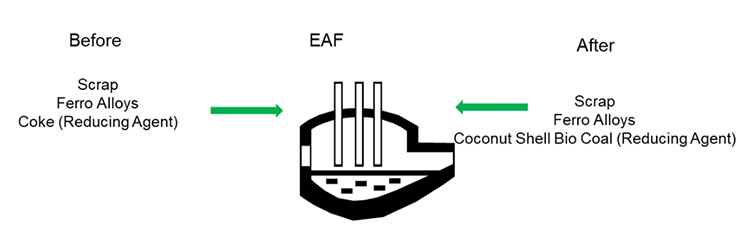

Characteristics Comparison Between Bio-Coal and Coke in Steel Industry

The following table shows how Bio-Coal simply outperforms coke from coal.

| Chemistry Compare | |||

|---|---|---|---|

| Characteristics | UOM | Bio Coal | Coke |

| Moisture | % | 5.5 | 15 |

| VM | % | 15.16 | 2.3 |

| Ash | % | 2.33 | 16 |

| Fixed Carbon | % | 82.51 | 81.3 |

| GCV | Kcal/Kg | 7000 | 6800 |

| Sulphur Content | % | 0.1 | 0.66 - 0.81 |

*Bio-Coal has higher calorific value comparing to regular coke from coal. Calorific value is the most important characteristics of a good fuel

Examining the data, bio-coal demonstrates a lower moisture content (5.5% vs. 15%) and significantly higher volatile matter (15.16% vs. 2.3%) compared to coke. Moreover, bio-coal exhibits lower ash content (2.33% vs. 16%) and a slightly higher fixed carbon composition (82.51% vs. 81.3%). Notably, the calorific value (GCV) of bio-coal surpasses that of coke (7000 Kcal/Kg vs. 6800 Kcal/Kg), suggesting enhanced energy potential. Furthermore, the negligible sulphur content in bio-coal (0.1%) aligns with environmental considerations.

Calorific Value

Bio-coal presents a promising alternative to traditional metallurgical coke due to its competitive calorific value. The calorific value of bio-coal, expressed in kilocalories per kilogram (KCal/kg), is a crucial parameter influencing the energy efficiency of metallurgical processes. In comparison to metallurgical coke, bio-coal exhibits 7000 Kcal/kg, indicating its potential as an energy-rich substitute which is comparable to Metallurgical Coke being used in the process with energy value of 6800 Kcal/kg.

Reactivity and Combustion Characteristics

The reactivity of bio-coal during combustion significantly impacts temperature profiles and overall combustion efficiency in metallurgical processes. The average tapping temperature during the trail was remained at around 1560 degree Celsius using bio-coal which was in accordance with the desired outcome.

High Fixed Carbon Content

The fixed carbon content in bio-coal contributes significantly to its energy content. Comparative analysis with metallurgical coke fixed carbon composition (81.3%) & Bio-Coal fixed carbon composition (82.51%) provides insights into the potential of bio-coal as an energy source in metallurgical applications. The fixed carbon content is integral to understanding the combustion efficiency and energy release during the process, carburizing effect, better Slag Foaming: protect Lining & better Reducing property.

Low Sulfur Content

Lower sulfur content translates to reduced sulfur dioxide (SO2) emissions during combustion, lower sulfur content supports improved air quality and human health. Sulfur content in bio-coal is a critical parameter with environmental implications. Comparative studies indicate Bio-Coal with sulfur content less than 0.12% of bio-coal and its potential impact on emissions. Low sulfur content aligns with sustainable and green initiatives, making bio-coal an attractive option for industries aiming to reduce their environmental impact and promote corporate social responsibility.

Low Carbon Footprint

Bio-coal is derived from biomass sources, which absorb carbon dioxide (CO2) during their growth. As a result, the combustion of bio-coal releases CO2 that was recently captured, making it a carbon-neutral or even a carbon-negative fuel source. The substitution of bio-coal for coke in metallurgical processes can directly contribute to reducing the greenhouse gas intensity of these operations..