HISAR

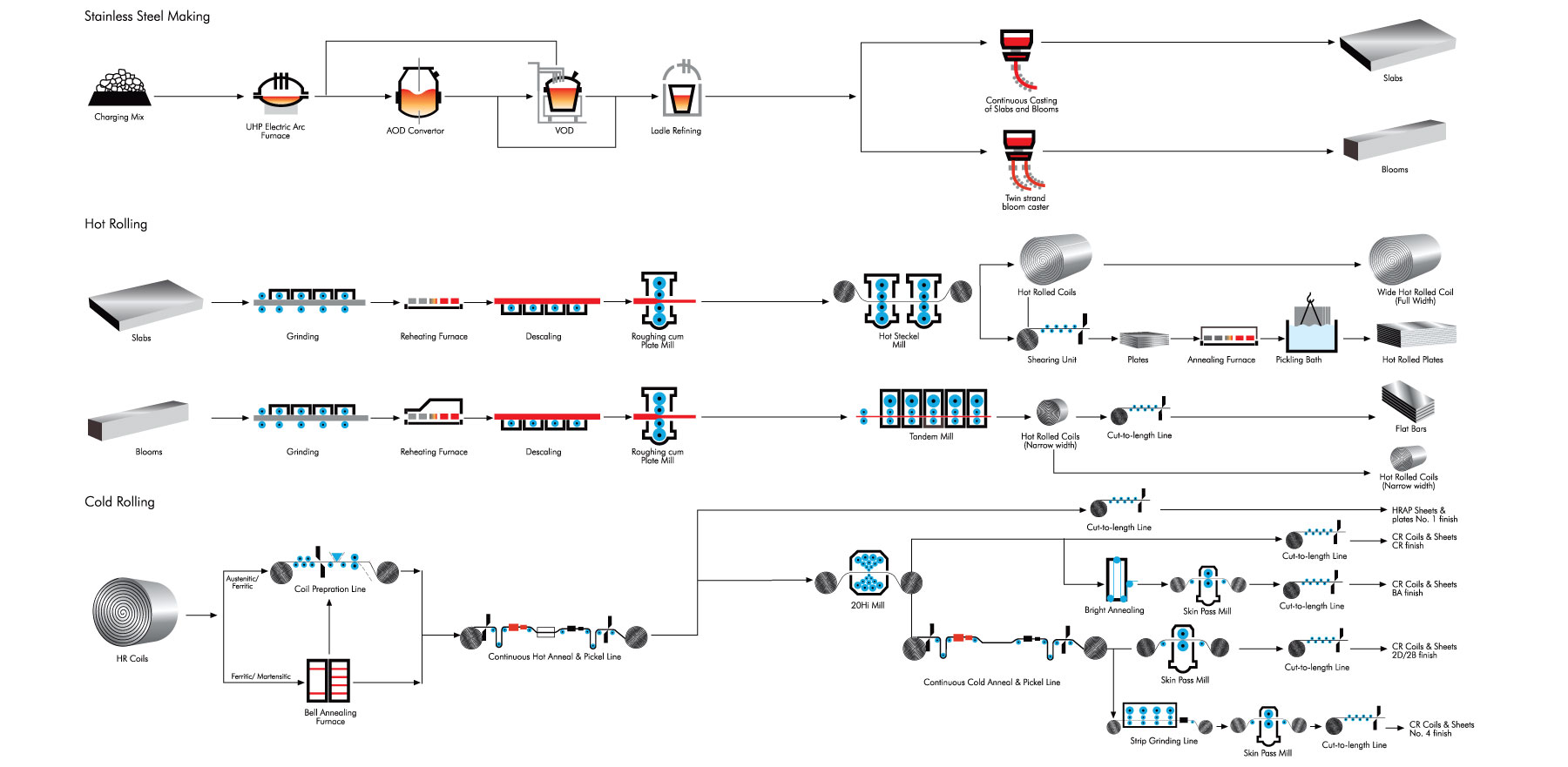

STAINLESS STEEL MAKING

The state-of-art Melt & Casting Shops have an installed capacity of 800,000 tons per annum

| Equipment | No. | |

|---|---|---|

| 2 Electric Arc and 1 Induction Furnace | 02 | 45MT & 45MT |

| AOD Convertor | 02 | 50MT each |

| VOD | 01 | 50MT |

HOT ROLLING

Hot Rolling Complex comprises of 4-Hi Twin Stand Hot Steckel Mill and Tandem Strip Mill with a total capacity of 720,000 tons per annum & 300,000 tons per annum respectively. Hot Steckel Mill consists of a Walking Beam Reheating furnace, Roughing Stand, two Finishing Stand and a Walking Beam Slab Reheating Furnace. The Tandem Strip mill comprises of Reheating Furnace, Roughing Stand, five Finishing Stands and Down Coiler.

The complex also consists of Plate Annealing & Pickling facilities along with Shot Blasting,

Straightening & Leveling equipment to produce Stainless Steel Plates of various grades.

COLD ROLLING

Cold Rolling Complex has a capacity to produce 375,000 tons per annum of Cold Rolled Stainless Steel Flat products.

The complex is equipped with four 20 Hi-Sendzimir Cold Rolling Mills, three continuous Anneal and Pickle lines, three of these are equipped with Electrolytic Pickling, one bright Annealing Line, three Coil Preparation Lines, five Slitting Lines, one cut to length Leveling and Sheet Shearing Line with associated facilities.

Jindal Stainless is fully equipped to produce material with No.1, 2D, 2B, BA, N3 and No.4 and customised surface finish. It can also produce other specialized finishes such as moon rock, honey comb, Scotch Bright, embossed, hairline, box and lenin.

SPECIALITY PRODUCTS

Speciality Product Complex has a capacity of 84,000 tons per annum of precision cold rolled strips. This complex processes mainly martensitics Stainless Steel for razor blade manufacturing

The Speciality Product Complex comprises of processing equipment, primarily for annealing, rolling and finishing. There is an option of using either a Bell Annealing or a Bright Annealing or even Pull- through Annealing, depending on the grade and finish, of Stainless Steel being produced.

4-Hi mills and 20-Hi mills are used for reduction rolling to thinner gauges with close thickness tolerances. To impart various finishes in the final products, the complex has Strip Grinding Line, Skin Pass Mill and Tension Leveler. Such product then passes through the Precision Slitters to achieve precise dimensions.

The razor blade cold rolled strips of up to 0.076mm thickness are produced in this complex and supplied to leading Indian and International razor blade manufacturers.

The company also has the capability of producing ferritic Stainless Steel and Non-Ferrous coin blanks. The present installed capacity of coin blank unit is 9,125 tons per annum.

PROCESS FLOW -HISAR

Jajpur, Odisha

FERRO ALLOYS

Mining of ore is key to the integration process. Jindal Stainless has Chrome Ore open cast mines at Sukinda, Odisha to support 250,000 tons per annum capacity Ferro Chrome plant at Jajpur.

In the first phase of the Odisha project, Jindal Stainless has set up Captive Power Plants, Coke Oven Batteries and Submerged Arc Furnaces to produce Ferro Alloys.

As part of this project, 2 x 60 MVA furnaces, largest in India, with capacity of 150,000 tons per annum are already in operation and producing

High Carbon Ferro Chrome (HCFC). These state-of-the-art furnaces and the Briquetting Press have been supplied by SMS DeMAG AG, and Kopern Maco of Germany respectively. The waste heat of these semi closed furnaces are utilized to generate 13MW power

The Ferro Alloys complex also comprises of 1 x 27.6 MVA Ferro Manganese and 2 x 27.6 MVA Silico Manganese Furnaces supplied by Sibeltherm, Russia to produce 100,000 tons per annum. This complex is also equipped with modern de-dusting, pollution control and waste management systems.

| Plant & Facility | Current | Future Expansion | Full Development |

|---|---|---|---|

| Ferro Chrome Plant | 2 x 60 MVA (150,000 tpa) | 4 x 60 MVA (300,000 tpa) | 6 x 60 MVA (450,000 tpa) |

| Ferro Manganese Plant | 1 x 27.6 MVA ( 50,000 tpa) | 1 x 27.6 MVA ( 50,000 tpa) | 2 x 27.6 MVA ( 100,000 tpa) |

| Silica Manganese Plant | 2 x 27.6 MVA ( 50,000 tpa) | 2 x 27.6 MVA ( 50,000 tpa) | 4 x 27.6 MVA (100,000 tpa) |

COKE OVEN

Jindal Stainless has installed one 64-chamber stamp-charging Coke Oven Battery to produce 430,000 tons per annum with recovery of by-products such as Coal Tar, Ammonium Sulphate, Sulphur and Coke Oven Gas. The Coke Oven Gas will be utilized in Reheating furnace for preheating of slabs for Hot Rolling. With same by-product plant, another battery will be added to double the capacity to 860,000 tons per annum.

| Plant & Facility | Current | Future Expansion | Full Development |

|---|---|---|---|

| Coke Oven Battery | 430,000 tpa | 430,000 tpa | 860,000 tpa |

CAPTIVE POWER PLANT

To fulfill its power requirement, Jindal Stainless has set up 2 x 125 MW captive thermal Power Plant, configured with Pulverised Coal Fired steam generators with provisions to double the capacity. This Captive Power Generation will lead to cost rationalisation and increased competitiveness.

| Plant & Facility | Current | Future Expansion | Full Development |

|---|---|---|---|

| Coke Oven Battery | 430,000 tpa | 430,000 tpa | 860,000 tpa |

STAINLESS STEEL COMPLEX

The Stainless Steel complex at Jajpur, Odisha has a current capacity of 2.2 million tons per annum

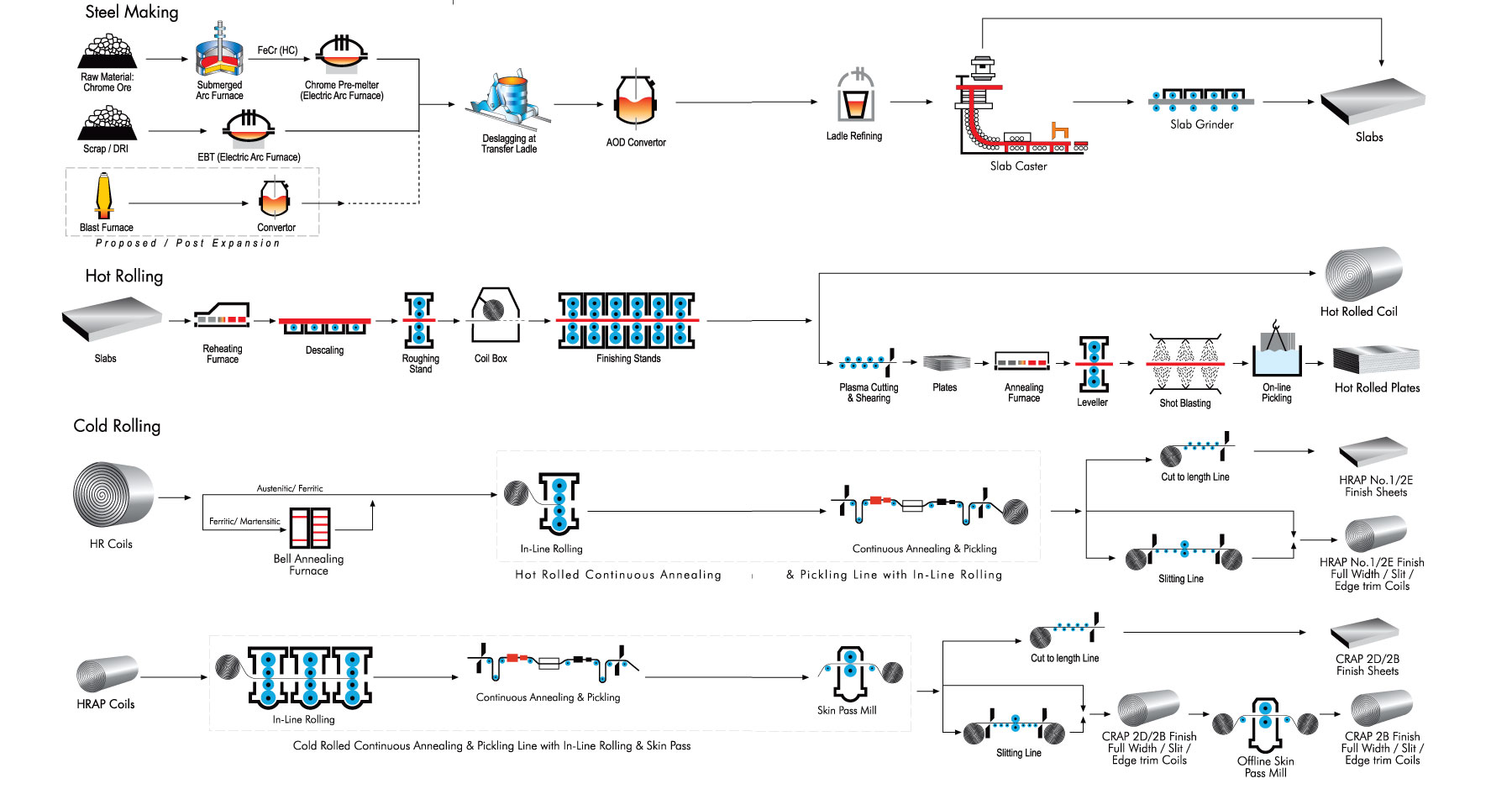

Stainless Steel Making

Stainless Steel melt shop complex has been designed and supplied by SMS SIEMAG of Germany and is based on liquid ferrochrome utilization along with hot metal from submerged arc furnace of Fe Alloys plant. Instead of solid ferrochrome, molten ferrochrome from the Submerged Arc Furnaces is directly fed and liquid steel is produced in EAF. The liquid steel is then properly mixed with chromium pre-melt in a ladle for subsequent operation in AOD vessel for making Stainless Steel as per desired specifications.

At scrap yard the charge is prepared from the stock of scrap and other raw material in the scrap yard. Charge mix is made according to grade of steel and charged into the Electric Arc Furnace (EAF) by over head crane from buckets.

In Raw Material Handling system, which is common to both EAF and AOD, all the materials added from over head bins are stored, weighed and used via conveyor belts as per requirement.

Hot Rolling

The 1 million tons per annum Hot Rolling Complex has been designed and supplied by Siemens VAI of Austria and consists of a 6-Stand Tandem hot rolling mill with a single-stand Rougher. The mill is equipped with latest technological equipment such as a fully hydraulic edger, long-stroke HAGC in all mill stands, L-block bending, shifting devices in conjunction with the Smart Crown® system and for superior profile and flatness control. This Tandem mill is designed to handle coil weights upto 36 tons. Stainless Steel plates will be extracted via the downcoiler area with a plate dividing shear and a plate piler. The plates will then be taken to the plate finishing area with annealing and cutting facilities.

The 300 tons per hour Walking Beam Furnace is designed and supplied by Five Stein of France. The furnace will utilise the Coke Oven Gas for heating of Stainless Steel slabs to optimise energy consumption thus reducing overall cost.

The production capacity of this mill can be increased to 3.2 million tons per annum by addition of a Reheating Furnace, a 7th Mill Stand and a Downcoiler.

Cold Rolling

The Cold Rolling Complex has been designed and supplied by Andritz of Austria and has a unique feature of In-line rolling with Annealing and Pickling lines which will result in reduced processing cost due to higher yield and productivity. The Hot Rolled Anneal and Pickle (HRAP) line with single-stand In-line rolling can produce 2E products along with HRAP coils with No.1 finish. The Cold Rolled Anneal and Pickle (CRAP) line comprising of 3-Stand In-line rolling can produce various thickness, grades and finishes. Both these lines can handle coil weight upto 40 tons.

An Air Separation Plant will supply gases such as Oxygen, Nitrogen and Argon. Lime and Dololime Plant will supply required quality and quantity of Lime/Hydrated Lime and Dolomite. In addition, the Jaipur integrated Stainless Steel facility is supported by a Central Raw Material Handling system and an in-house Railway network to facilitate inbound and outbound movement of raw materials and finished products.

| Plant & Facility | Capacity (million tpa) | Further Expansion (million tpa) | Full Development (million tpa) |

|---|---|---|---|

| Stainless Steel Melt Shop | 1.1 | 1.6 | - |

| Re-Heating Furnace | 300 tph | - | 300 tph |

| Hot Strip Tandem Mill | 1.6 | - | 1.6 |

| Hot Rolled Anneal Pickle | 0.95 | - | 1.6 |

| Cold Rolled Anneal Pickle | 0.45 | - | 0.95 |

Stainless Steel Industrial Park

Jindal Stainless will develop a Stainless Steel Industrial Park adjacent to its 1.1 million per annum Stainless Steel plant in Odisha. Jindal Stainless will support in developing down stream units. The area for this industrial Park is about 300 acres including both SEZ and Non-SEZ areas. The Industrial Park will have a large Service Centre and various facilities to produce Stainless Steel products for applications in Architectural Building & Construction , Transportation, Industrial & Consumer Goods and in Kitchenwares & Lifestyle. The Service Center will process the coils from Stainless Steel Plant and provide customised sizes to the facilities in the Industrial Park.

Jindal Stainless will develop, operate and maintain this Industrial Park and the associated infrastructure including education, recreation and healthcare facilities. Jindal Stainless is committed to develop this Industrial Park in to a world class Stainless Steel manufacturing hub and invite investors to put their facilities in this park focusing on Stainless Steel products. Jindal Stainless assures long term Stainless Steel availability at concessional rates in addition to availability of land, power, water and other infrastructure such as warehouses, road and railway networks.

This Industrial Park will be a world class Stainless Steel manufacturing hub

PROCESS FLOW -ODISA

Finishes & Applications

| Surface Finish | Type of Process Route | Description | Applications | |

|---|---|---|---|---|

| ASTM A480 | EN 10088-2 | |||

| No 1 | 1D | Hot Rolled, annealed and pickled | This is a dull, non-reflective finish. Not as smooth as 2D or 2B | Pipes, tubing, chemical tank, general fabrication |

| No 2D | 2D | Cold Rolled, annealed and pickled | Surface is not as smooth as 2B or BA | Deep drawn utensils, heat exchanger, automotive exhaust systems |

| No 2B | 2B | Cold Rolled, annealed, pickled and skin passed | Smoother than 2D | Food and beverage industry, kitchen utensils, medical equipment, construction material, dairy equipment |

| BA | 2R | Cold Rolled, bright annealed | A smooth, bright, reflective, finish produced in inert atmosphere annealing | Decorative usage, kitchen utensils, electric equipment, building construction |

| No 3 | - | Cold Rolled, annealed, pickled and polished with 100 to 120 grit | Ground unidirectional finish. This is not highly reflective. | Kitchen and restaurant equipment, food and beverage industry and dairy equipment, medical equipment, architectural structures, building construction |

| No 4 | - | Cold Rolled, annealed, pickled and polished with 150 to 180 grit | Ground unidirectional finish, generally more smoother then No 3 finish. | Kitchen and restaurant equipment, food and beverage industry and dairy equipment, medical equipment, architectural structures, building construction |

| 2J | - | Grinding 2B finish with suitable abrasive belt followed by brushing in the same pass | No4 finish with brush polish | External panels of metro/rail coaches, lift interiors, bus shelters, decorative panels, architectural applications |

| Scotch Brite | - | Polishing with rolls made out of scotch brite material | Unidirectional finish is produced by polishing with scotch brite rolls.This finish is more smoother than No4 finish | Architectural purposes, railway cabins, elevator interiors, panelling, kitchen appliances |

| Hot Rolled Chequered* | 1M Patterned | Chequered Pattern produced in hot strip mill followed by annealing and pickling | Hot Rolled Chequered Sheets/Plates having raised patterns imparted by hot rolling mills on one surface of the coil | Industrial, walkways, staircase & railway coaches flooring & footrest application |

*Chequered Pattern conforms to BIS 3502 (Pattern 1C)

Data Sheet

|

Jindal Designation/code |

%C (Max) |

%Mn (Max) |

%P (Max) |

%S (Max) |

%Si (Max) |

%Cr | %Ni | %Mo |

N PPM (Max) |

% Others |

|---|---|---|---|---|---|---|---|---|---|---|

| J-301 | 0.15 | 2.00 | 0.045 | 0.030 | 1.00 | 16.00-18.00 | 6.00-8.00 | - | 1000 | |

| J-301L | 0.030 | 2.00 | 0.045 | 0.030 | 1.00 | 16.00-18.00 | 6.00-8.00 | - | 2000 | |

| J-301LN | 0.030 | 2.00 | 0.045 | 0.030 | 1.00 | 16.00-18.00 | 6.00-8.00 | 700-2000 | - | |

| J-304 | 0.07 | 2.00 | 0.045 | 0.030 | 0.750 | 17.50-19.50 | 8.00-10.50 | 1000 | ||

| J-304H | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 0.75 | 18.00-20.00 | 8.00-10.50 | - | - | - |

| J-304L | 0.030 | 2.00 | 0.045 | 0.030 | 0.75 | 17.50-19.50 | 8.00-12.00 | - | 1000 | - |

| J-304LN | 0.030 | 2.00 | 0.045 | 0.030 | 0.750 | 18.00-20.00 | 8.00-12.00 | 1000-1600 | ||

| J-30815 | 0.05-0.10 | .80 | 0.04 | 0.03 | 1.4-2.00 | 20.00-22.00 | 10.00-12.00 | 1400-2000 | Ce=0.03-0.08 | |

| J-309S | 0.08 | 2.00 | 0.045 | 0.030 | 0.75 | 22.00-24.00 | 12.00-15.00 | - | - | - |

| J-310S | 0.08 | 2.00 | 0.045 | 0.030 | 1.50 | 24.00-26.00 | 19.00-22.00 | - | - | - |

| J-316 | 0.08 | 2.00 | 0.045 | 0.030 | 0.75 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | 1000 | |

| J-316L | 0.030 | 2.00 | 0.045 | 0.030 | 0.75 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | 1000 | |

| J-316LN | 0.030 | 2.00 | 0.045 | 0.030 | 0.75 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | 1000-1600 | |

| J-316Ti | 0.08 | 2.00 | 0.045 | 0.030 | 0.75 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | 1000 | Ti-5X(C+N) Min., 0.70 Max. |

| J-317 | 0.08 | 2.00 | 0.045 | 0.030 | 0.75 | 18.00-20.00 | 11.00-15.00 | 3.00-4.00 | 1000 | - |

| J-317L | 0.030 | 2.00 | 0.045 | 0.030 | 0.75 | 18.00-20.00 | 11.00-15.00 | 3.00-4.00 | 1000 | - |

| J-317LN | 0.030 | 2.00 | 0.045 | 0.030 | 0.75 | 18.00-20.00 | 11.00-15.00 | 3.00-4.00 | 1000-2200 | - |

| J-31727 | 0.030 | 1.00 | 0.030 | 0.030 | 1.00 | 17.50-19.00 | 14.50-16.50 | 3.80-4.50 | 1500-2100 | Cu- 2.8-4.0 |

| J-321 | 0.08 | 2.00 | 0.045 | 0.030 | 0.75 | 17.00-19.00 | 9.00-12.00 | - | 1000 | Ti=5X(C+N) Min., 0.70 Max. |

| J-347 | 0.080 | 2.00 | 0.045 | 0.030 | 0.750 | 17.00-19.00 | 9.00-13.00 | - | Nb- 10XC Min., 1.00 Max. | |

| J-904L | 0.02 | 2.00 | 0.05 | 0.04 | 1.00 | 19.00-23.00 | 23.00-28.00 | 4.00-5.00 | 1000 | Cu=1.00-2.00 |

|

Jindal Designation/code |

Tensile Strength (MPA)min. | %Yield Strength(MPA)min. | %Elongation(min.) | Hardness (HRB)max. |

|---|---|---|---|---|

| J-301 | 515 | 205 | 40 | 95 |

| J-301L | 550 | 220 | 45 | 100 |

| J-301LN | 550 | 240 | 45 | 100 |

| J-304 | 515 | 205 | 40 | 92 |

| J-304H | 515 | 205 | 40 | 92 |

| J-304L | 485 | 170 | 40 | 92 |

| J-304LN | 515 | 205 | 40 | 95 |

| J-30815 | 600 | 310 | 40 | 95 |

| J-309S | 515 | 205 | 40 | 95 |

| J-310S | 515 | 205 | 40 | 95 |

| J-316 | 515 | 205 | 40 | 95 |

| J-316L | 485 | 170 | 40 | 95 |

| J-316LN | 515 | 205 | 40 | 95 |

| J-316Ti | 515 | 205 | 40 | 95 |

| J-317 | 515 | 205 | 35 | 95 |

| J-317L | 515 | 205 | 40 | 95 |

| J-317LN | 550 | 240 | 40 | 95 |

| J-31727 | 550 | 245 | 35 | 96 |

| J-321 | 515 | 205 | 40 | 95 |

| J-347 | 515 | 205 | 40 | 92 |

| J-904L | 490 | 220 | 35 | 90 |

|

Jindal Designation/code |

BIS Grade Designation |

%C (Max) |

%Mn (Max) |

%P (Max) |

%S (Max) |

%Si (Max) |

%Cr | %Ni | %Mo |

N PPM (Max) |

% Others |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 201 | 201 | 0.15 | 5.50-7.50 | 0.06 | 0.015 | 0.75 | 16.0-18.0 | 3.50-5.50 | - | 2500 | - |

| J-201L | 201S | 0.030 | 5.50-7.50 | 0.045 | 0.015 | 0.75 | 16.00-18.00 | 3.50-5.50 | - | 2500 | - |

| 201LN | 201LN | 0.030 | 6.40-7.50 | 0.045 | 0.015 | 0.75 | 16.0-17.50 | 4.0-5.0 | - | 1000-2500 | Cu = 1.0 Max |

| 202 | 202 | 0.150 | 7.5-10.0 | 0.060 | 0.015 | 0.75 | 17.00-19.00 | 4.0-6.0 | - | 2500 | - |

| J204Cu | N2 | 0.10 | 6.5-9.0 | 0.070 | 0.015 | 0.75 | 16.0-17.0 | 1.5-3.5 | - | 1000-2500 | Cu - 2.0-4.0 Max |

| JSL AUS | N3 | 0.080 | 6.0-8.0 | 0.070 | 0.015 | 0.75 | 16.0-17.5 | 4.0-6.0 | - | 500-1500 | Cu - 1.5-2.0 Max |

| J4 | N1 | 0.12 | 8.5-10.0 | 0.080 | 0.015 | 0.75 | 15.0-16.0 | 1.0-2.0 | - | 1000-2000 | Cu = 1.50-2.0 Max |

| JSLU DD | N1 | 0.12 | 9.0-10.5 | 0.080 | 0.015 | 0.75 | 15.0-16.0 | 1.0-2.0 | - | 1000-2000 | Cu = 1.75-2.50 Max |

| JSLU SD-M | N7 | 0.14 | 9.0-11.0 | 0.10 | 0.015 | 0.75 | 14.0-15.0 | 0.6-0.95 | - | 1000-2000 | Cu = 0.6-0.8 Max |

| JT | N7 | 0.13 | 9.0-11.0 | 0.10 | 0.015 | 0.75 | 13.5-15.0 | 0.5-0.95 | - | 1000-2000 | Cu = 0.4-0.8 Max |

|

Jindal Designation/Grade |

Tensile Strength MPa (min) | Yeild Strength MPa (min) | % Elongation (min) | Hardness Rockwell B (Max) |

|---|---|---|---|---|

| J-201 | 655 | 310 | 40 | 100 |

| J-201L | 655 | 310 | 40 | 100 |

| J-201LN | 655 | 310 | 45 | 100 |

| J-202 | 620 | 260 | 40 | 100 |

| J-204Cu | 620 | 310 | 40 | 100 |

| JSLAUS (J1) | 550 | 205 | 40 | 95 |

| J-4 | 650 | 325 | 40 | 100 |

| JSL U DD | 700 | 350 | 40 | 100 |

| JSL U SD | 700 | 350 | 40 | 100 |

| JT | 700 | 350 | 40 | 100 |

|

Jindal Designation/code |

%C (Max) |

%Mn (Max) |

%P (Max) |

%S (Max) |

%Si (Max) |

%Cr | %Ni | %Mo |

N PPM (Max) |

% Others |

|---|---|---|---|---|---|---|---|---|---|---|

| J-410 | 0.08-0.15 | 1.00 | 0.040 | 0.030 | 1.00 | 11.50-13.50 | 0.75 max | - | - | - |

| J-415 | 0.05 | 0.50-1.00 | 0.030 | 0.030 | 0.60 | 11.50-14.00 | 3.50-5.50 | 0.50-1.00 | - | - |

| J-420 | 0.15 min | 1.00 | 0.040 | 0.030 | 1.00 | 12.00-14.00 | 0.75 max | 0.50 max | - | - |

| J-420J1 | 0.16-0.25 | 1.00 | 0.040 | 0.030 | 1.00 | 12.00-14.00 | 0.6 | - | - | - |

| J-420J2 | 0.26-0.40 | 1.00 | 0.040 | 0.030 | 1.00 | 12.00-14.00 | 0.6 | - | - | - |

| J-420MoV | 0.45-0.55 | 1.00 | 0.040 | 0.015 | 1.00 | 14.00-15.00 | - | 0.50-0.80 | - | V=0.10-0.20 |

| J-431 | 0.20 | 1.00 | 0.040 | 0.030 | 1.00 | 15.00-17.00 | 1.25-2.50 | - | - | - |

| JBS | 0.6-0.7 | 1.00 | 0.028 | 0.020 | 0.75 | 12.50-13.50 | - | - | - | - |

| J-405 | 0.08 | 1.00 | 0.040 | 0.030 | 1.00 | 11.50-14.50 | 0.60 | - | - | AI=0.10-0.30 |

|

Jindal Designation/code |

Tensile Strength (MPA)min. | %Yield Strength(MPA)min. | %Elongation(min.) | Hardness (HRB)max. |

|---|---|---|---|---|

| J-410 | 450 | 205 | 20 | 96 |

| J-415 | 795 | 620 | 15 | 32HRC |

| J-420 | 690 | - | 15 | 96 |

| J-420J1 | 520 | 225 | 18 | 97 |

| J-420J2 | 540 | 225 | 19 | 99 |

| J-420MoV | 850 max | - | 12 | 100 |

| J-431 | - | - | - | 29HRC |

| JBS | - | - | - | - |

| J-405 | 415 | 170 | 20 | 88 |

|

Jindal Designation/code |

%C (Max) |

%Mn (Max) |

%P (Max) |

%S (Max) |

%Si (Max) |

%Cr | %Ni | %Mo |

N PPM (Max) |

% Others |

|---|---|---|---|---|---|---|---|---|---|---|

| J-409L | 0.030 | 1.00 | 0.040 | 0.020 | 1.00 | 10.50-11.70 | 0.50 max | - | 300 | Ti=6X (C+N) Min, 0.75 Max |

| J-409Ni | 0.030 | 1.00 | 0.040 | 0.030 | 1.00 | 10.50-11.70 | 0.50-1.00 | - | 300 | Ti=6X(C+N) Min, 0.75 Max |

| J-410S | 0.08 | 1.00 | 0.040 | 0.030 | 1.00 | 11.50-13.50 | 0.60 max | - | - | - |

| J-430 | 0.12 | 1.00 | 0.040 | 0.030 | 1.00 | 16.00-18.00 | 0.75 max | - | - | - |

| J-432 | 0.025 | 1.000 | 0.040 | 0.030 | 1.00 | 17.00-20.00 | - | 0.40-.80 | 250 | Ti/Nb=8X(C+N) Min, 0.80 Max |

| J-436 | 0.120 | 1.00 | 0.040 | 0.030 | 1.00 | 16.00-18.00 | - | 0.75-1.25 | - | Nb= 5XC Min., 0.70 Max. |

| J-436L | 0.025 | 1.00 | 0.040 | 0.030 | 1.00 | 16.00-19.00 | - | 0.75-1.25 | 250 | % Nb or & Ti or % combination = 8X (C+N) Min, 0.80 Max |

| J-439 | 0.030 | 1.00 | 0.040 | 0.030 | 1.00 | 17.00-19.00 | 0.50 max | - | 300 | Ti=0.20+4X (C+N) |

| J-441 | 0.030 | 1.00 | 0.040 | 0.015 | 1.00 | 17.50-18.50 | - | - | - | Nb=3X% C+0.3 Min. |

| J-444 | 0.025 | 1.00 | 0.040 | 0.030 | 1.00 | 17.50-19.50 | 1.00 | 1.75-2.50 | 350 | (Ti+Nb) 0.20+4(C+N) |

| J-446 | 0.20 | 1.50 | 0.040 | 0.030 | 1.00 | 23.00-27.00 | 0.75 | - | 2500 | - |

| J-430J1L | 0.025 | 1 | 0.04 | 0.03 | 1.00 | 16.00-20.00 | - | - | 250 | Cu =0.3-0.8,Nb =8X(C+N)Min, 0.80 Max |

|

Jindal Designation/code |

Tensile Strength (MPA)min. | %Yield Strength(MPA)min. | %Elongation(min.) | Hardness (HRB)max. |

|---|---|---|---|---|

| J-409L | 380 | 170 | 20 | 88 |

| J-409Ni | 415 | 275 | 20 | 92 |

| J-410S | 415 | 205 | 22 | 89 |

| J-430 | 450 | 205 | 22 | 89 |

| J-432 | 410 | 245 | 20 | 96 |

| J-436 | 450 | 240 | 22 | 89 |

| J-436L | 410 | 245 | 20 | 96 |

| J-439 | 415 | 205 | 22 | 89 |

| J-441 | 430 | 250 | 18 | 88 |

| J-444 | 415 | 275 | 20 | 96 |

| J-446 | 515 | 275 | 20 | 96 |

| J-430J1L | 205 | 390 | 22 | 90 |

| Jindal Designation/code |

%C (Max) |

%Mn (Max) |

%P (Max) |

%S (Max) |

%Si (Max) |

%Cr | %Ni | %Mo |

N PPM (Max) |

% Others |

|---|---|---|---|---|---|---|---|---|---|---|

| J-409M | 0.030 | .8-1.5 | 0.040 | 0.030 | 1.00 | 10.50-12.50 | 1.50 max | - | 300 | Ti=0.75 Max |

| Jindal Designation/code | Tensile Strength (MPA)min. | %Yield Strength(MPA)min. | %Elongation(min.) | Hardness (HRB)max. |

|---|---|---|---|---|

| J-409M | 450 | 275 | 20 | 90 |

|

Jindal Designation/code |

%C (Max) |

%Mn (Max) |

%P (Max) |

%S (Max) |

%Si (Max) |

%Cr | %Ni | %Mo |

N PPM (Max) |

% Others |

|---|---|---|---|---|---|---|---|---|---|---|

| J-2205 | 0.030 | 2.00 | 0.030 | 0.020 | 1.00 | 22.00-23.00 | 4.50-6.50 | 3.0-3.50 | 1400-2000 | - |

| J-2304 | 0.030 | 2.50 | 0.040 | 0.030 | 1.00 | 21.50-24.50 | 3.00-5.50 | 0.05-0.60 | 500-2000 | Cu 0.05 - 0.60 |

| J-32101* | 0.040 | 4.00-6.00 | 0.040 | 0.030 | 1.00 | 21.0-22.0 | 1.35-1.70 | 0.10-0.80 | 0.20-0.25 | Cu 0.10 - 0.80 |

| J32750 | 0.03 | 1.2 | 0.035 | 0.02 | 0.8 | 24.0-26.0 | 6.0-8.0 | 3-5 | 2400-3200 | Cu 0.5 Max |

| J32760 | 0.03 | 1.0 | 0.03 | 0.01 | 1.0 | 24.0-26.0 | 6.0-8.0 | 3-4 | 2000-3000 | Cu: 0.5 - 1.0, W: 0.5-1.0 |

|

Jindal Designation/code |

Tensile Strength (MPA)min. | %Yield Strength(MPA)min. | %Elongation(min.) | Hardness (HRB)max. |

|---|---|---|---|---|

| J-2205 | 655 | 450 | 25 | 31HRC |

| J-2304 | 600 | 400 | 25 | 32HRC |

| J-32101* | 700 | 530 | 30 | 31HRC |

| J32750 | 550 | 795 | 15 | 32HRC |

| J32760 | 550 | 750 | 25 | 32HRC |

Grades other than these can also be manufactured. Specific chemical and mechanical properties can also be supplied by mutual agreement.