Maintenance Costs

Expected Lifespan

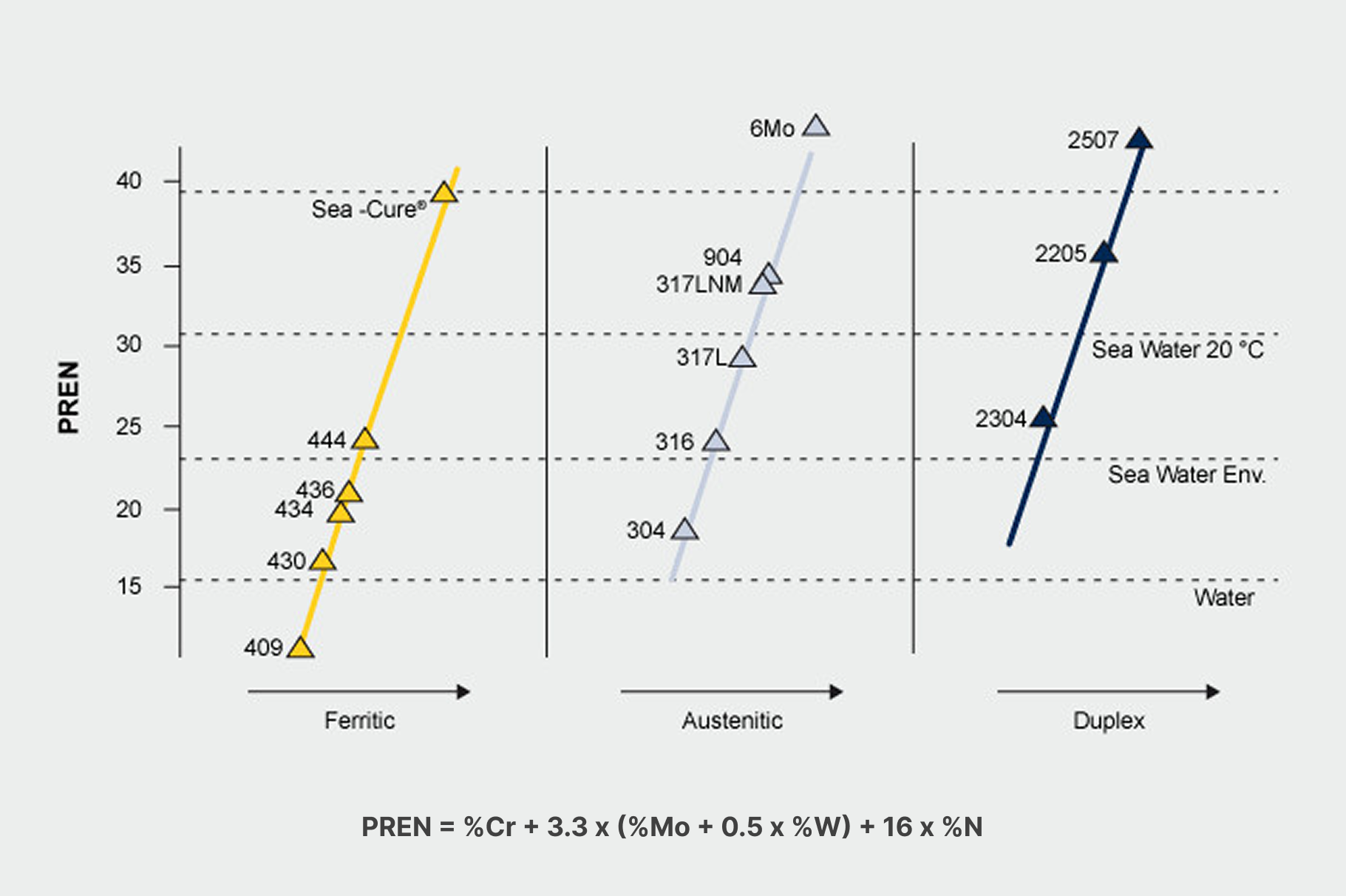

Corrosion Resistance

Monthly

Stainless Trivia

Fill in your answer

for Enhanced Durability and Reduced Maintenance Costs

This case study explores how Jindal Stainless Limited (JSL) supplied Stainless Steel 2304 to M/s Khimji Ramdas LLC in Oman, providing a superior solution to address marine challenges.

In the marine industry, harsh environmental conditions pose significant challenges to equipment durability and longevity. One such critical component is pontoons floating structures that support bridges, platforms, docks, and other marine constructions. Their primary function is to provide buoyancy and stability, ensuring the safe operation of marine infrastructure.

Traditionally, mild steel/galvanised steel has been used in pontoon manufacturing, but it is prone to corrosion and requires extensive maintenance and frequent replacements.

Pontoons in marine environments are subjected to:

Constant saltwater exposure

High humidity

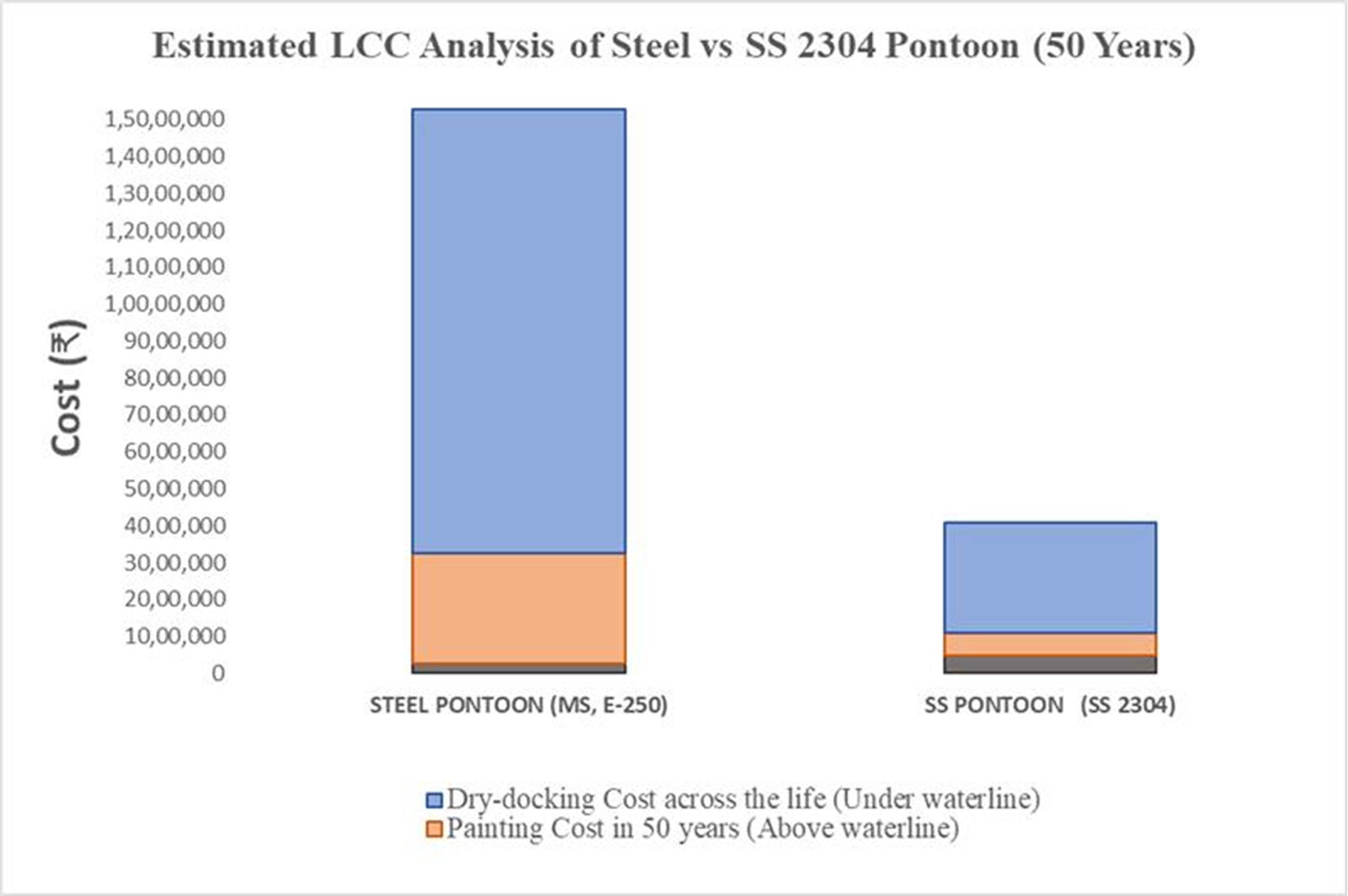

These conditions cause corrosion and degradation of materials such as mild steel. While initial cost savings are possible with traditional materials, the long-term maintenance and repair costs and operational breakdown far outweigh these benefits.

Image Source: Deltin Royal, Goa. Corrosion after 9 years.

As a result, the marine industry seeks materials that can withstand harsh environments while reducing maintenance costs and long life of the equipment.

In 2019, Jindal Stainless supplied 63 metric tonnes of SS 2304 plates to Khimji Ramdas LLC through M/s Toolfab Engineering Industries (P) Ltd, marking a significant shift from traditional materials to stainless steel for pontoon construction.

The pontoons were installed at Lima, Oman, by the Sultanate of Oman in 2020. To date (5 years and running), these pontoons have remained operational without requiring any maintenance, demonstrating the superior performance of stainless steel over traditional materials.

“Stainless Steel Pontoons (SS 2304), installed between April and May 2020, have remained maintenance-free and unpainted since installation, resulting in significant long-term cost savings.”

- Khimji Ramdas Official

Best-in-class corrosion protection in marine environments

Easier to handle, install, and transport due to their relatively lightweight compared to traditional materials

Lasts far longer than mild steel pontoon, minimising replacement costs and maximising lifecycle costs

Unlike mild steel, stainless steel requires minimal upkeep, leading to significant savings over their lifespan.

Withstands harsh conditions and heavy loads, ensuring long-term operational functionality

The SS pontoons maintain their aesthetic appeal over time without frequent upkeep or painting.

Ensures optimal buoyancy with lighter components

Performance Metric

Maintenance Costs

Expected Lifespan

Corrosion Resistance

Mild Steel Pontoons

Requires regular painting and repairs; up to 60% of the initial cost over its lifespan

20-25 years (with significant maintenance)

Requires regular corrosion protection measures

Stainless Steel Pontoons

Minimal to no maintenance since installation

60–75 years (with minimal to no maintenance)

Inherently corrosion-resistant, no additional protection needed

Given the outstanding performance of the stainless steel pontoons, M/s Khimji Ramdas LLC, Oman placed a second order in August 2024 for the development of 9 pontoons.

By successfully implementing stainless steel pontoons, Jindal Stainless has set a new standard in marine engineering. These resilient and sustainable structures tackle the challenges of harsh marine environments head-on, while ensuring long-term efficiency and reduced upkeep. This case, therefore, highlights the transformative power of stainless steel in marine applications.

The future of stainless steel in marine applications, especially pontoons, is promising and becoming the material of choice for:

Shipping Yard Companies

Petrochemicals, Refineries, Casino & Recreational Events

Renewable Energy