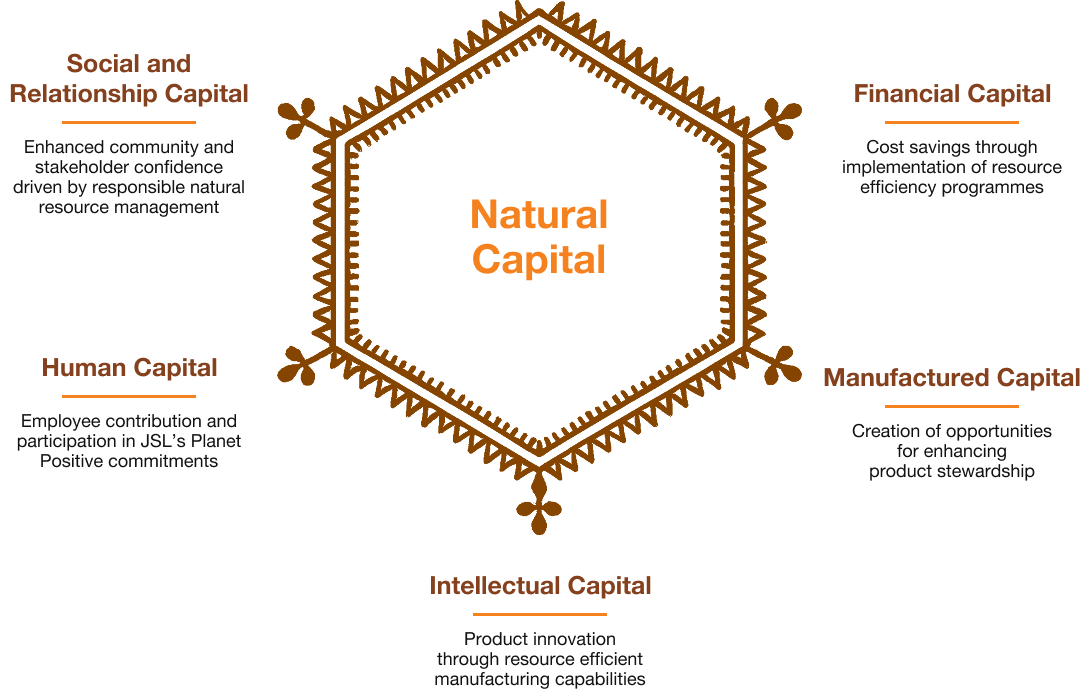

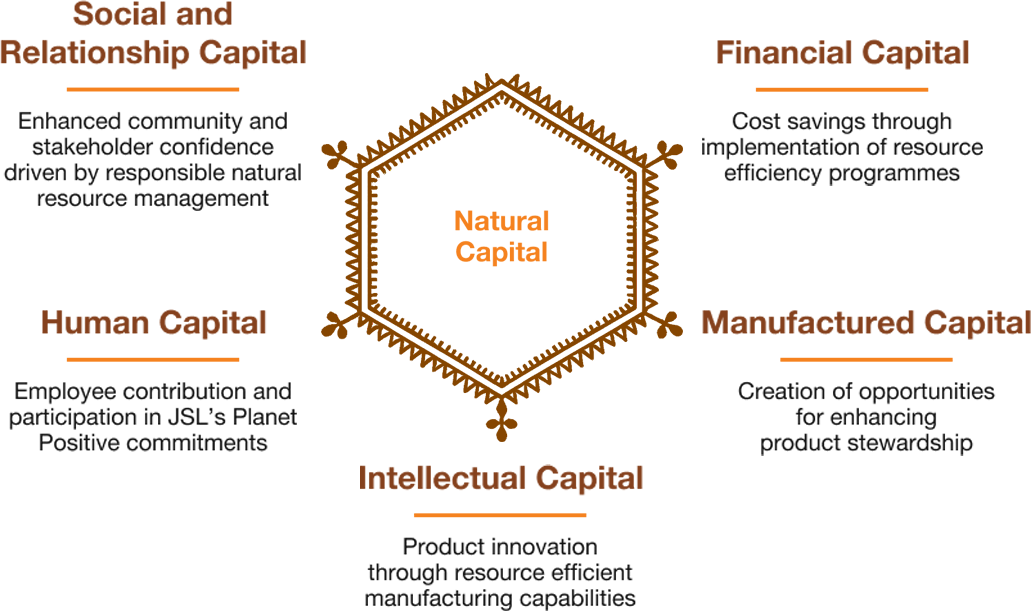

Interplay of Capitals

Policies

SDGs

Preserving and enhancing natural capital is fundamental to the long-term success of Jindal Stainless. As a business that operates in an energy- and resource- intensive sector, the company is acutely aware of its environmental responsibilities. The company’s approach focuses on minimising its ecological footprint, optimising resource efficiency, and actively contributing to the global transition towards a low-carbon, circular economy.

The company has achieved notable progress in reducing its environmental impact by embedding sustainability within its core operations. A key pillar of the company’s strategy is the circular use of materials. In FY25, JSL reused over 72% scrap in its stainless steel production process, significantly lowering the dependence on virgin raw materials while reducing emissions and waste.

Energy transition is another key priority of JSL. The company continues to scale up its use of renewable energy across operations. During the reporting year, the company consumed over 13,07,231 GJ of renewable energy, supported by infrastructure such as 28 MWp of rooftop solar and 7.3 MWp of floating solar installations, along with the development of a 1 GW hybrid renewable project.

The company’s commitment to water conservation is reflected through the implementation of zero-liquid discharge systems and rainwater harvesting mechanisms across its facilities. Water intensity stood at 7.36 m3 per ton of crude steel during the year. In addition, the company planted over 89,095 trees to enhance green cover and support local biodiversity.

JSL’s emission reduction efforts led to the avoidance of 3,18,248 tonnes of CO2 equivalent emissions, reinforcing its long-term climate ambition to achieve Net Zero by 2050. This is supported by the company’s science-aligned decarbonisation roadmap, with a near- term target to cut emissions by 50% by 2035.

Forging a Greener Future:

JSL’s Decarbonisation Roadmap

At Jindal Stainless, commitment to sustainability is forged into the very core of its business strategy. The company recognises that creating long-term value for its stakeholders is intrinsically linked to its responsibility to the planet. As a leader in the steel industry, JSL is not just adapting to the global transition towards a low-carbon economy; it is determined to be at the forefront of it, positioning itself as the customers’ first choice in sustainable stainless steel. The company’s business model is fundamentally based on the principles of a circular economy. By leveraging recycled materials and pioneering innovative, low-carbon production methods, it is actively shaping a more sustainable future. To translate this commitment into a clear, actionable strategy to achieve its goal of Net Zero by 2050, the company is undertaking a comprehensive decarbonisation analysis of its operations. This rigorous assessment will provide the company with a detailed, site-driven roadmap, outlining a multi-pronged approach to significantly reduce its greenhouse gas (GHG) emissions and chart a decisive course towards a sustainable future.

JSL’s Strategic Pathways to Decarbonisation

JSL is building a decarbonisation strategy with an aim to include a portfolio of carefully selected mitigation opportunities, demonstrating the potential to achieve a profound transformation in its environmental footprint. The company’s decarbonisation pathway is underpinned by three strategic pillars designed to systematically address its key emission sources.

Pillar 1: Generation and Energy Efficiency:

The foundation of JSL’s decarbonisation strategy is the relentless pursuit of efficiency. By optimising its processes and maximising resource utilisation, the company can achieve significant emissions reductions that are not only environmentally beneficial but also financially prudent. As per the JSL’s estimates, several key efficiency initiatives offer a negative abatement cost, meaning they generate cost savings while reducing the company’s carbon footprint.

Key initiatives include:

Pillar 2: A Technology-Led Transition to Cleaner Energy:

A core component of JSL’s decarbonisation roadmap is a deliberate and phased transition away from carbon-intensive fuels, guided by a clear technology roadmap. This involves embracing innovative technologies and sustainable feedstocks to fundamentally change how the company powers its operations.

The company’s transition plan includes:

Pillar 3: Greening the Value Chain and Empowering Customers:

JSL’s responsibility extends beyond its factory gates. The company is committed to addressing its Scope 3 emissions by building a sustainable supply chain and, crucially, by enabling its customers’ own green transitions.

Strategic initiatives include:

Alignment with Global Standards

JSL’s decarbonisation roadmap is designed to be robust, credible, and aligned with the highest global benchmarks. The company is looking at the possibilities of aligning the decarbonisation pathway with SBTi. This proactive alignment prepares JSL for emerging global standards like the European Sustainability Reporting Standards (ESRS) and the Corporate Sustainability Reporting Directive (CSRD), ensuring its disclosures remain transparent and valuable to its international stakeholders.

The Road Ahead

The journey to a low-carbon future is a continuous process of innovation, investment, and collaboration. JSL’s immediate next steps involve validating vendor credentials for key technologies, refining investment plans, and developing a phased implementation timeline with defined responsibilities for near-, mid-, and long-term actions. Achieving a net-zero target by 2050 for a stainless steel manufacturer in India is a technologically complex and capital-intensive endeavour that cannot be undertaken in isolation. Jindal Stainless is looking to collaborate with the government, think tanks, technology companies and the wider industry to ensure that this low-carbon transition remains a just transition.

By systematically executing this strategy, the company is confident that it will not only meet its environmental goals but also enhance its operational resilience, strengthen its competitive advantage, and continue to deliver sustainable value for decades to come.

Energy and Emissions

As a leading stainless steel manufacturer, JSL is committed to optimising energy consumption and minimising carbon emissions through advanced technologies, process improvements, and the integration of renewable energy solutions, ensuring both operational efficiency and environmental responsibility.

Managing Energy Responsibly

JSL’s Energy Management Policy outlines the company’s structured approach to reducing energy consumption and promoting sustainable practices across its operations. In alliance with the global standards and ISO 50001, the policy aims to improve energy performance year-on-year through targeted investments in efficient technologies, clean energy adoption, and innovation-led initiatives. It covers all employees, contractors, suppliers, and value chain partners, encouraging collaboration to lower energy use across the Board.

Key commitments include setting measurable energy targets, integrating energy-efficient design, and supporting research, training, and capacity- building. A dedicated budget is allocated towards renewable energy projects and fuel-switching programmes across locations. Regular internal energy audits are a key enabler for the company to systematically identify and capitalise on opportunities to optimise energy performance. These efforts are reinforced by systematic monitoring, stringent reporting, and structured engagement with stakeholders and regulatory authorities, enhancing accountability while driving measurable improvements.

JSL implements targeted energy efficiency training programmes covering topics across energy conservation, operational best practices, and renewable energy integration & usage, across all employee levels, to enhance awareness, encourage the adoption of best practices, and embed a culture of sustainability. Greater employee awareness and participation have a direct impact on achieving sustained reductions in energy consumption and enhanced operational effectiveness.

Measuring JSL’s Total Energy Consumption across the Years

| Fiscal Years | FY22 | FY23 | FY24 | FY25 |

|---|---|---|---|---|

| Total Renewable Energy Consumption (GJ) | 2,920 | 121,060 | 200,194 | 1,307,231 |

| Total Non-Renewable Energy Consumption (GJ) | 32,568,196 | 30,181,623 | 34,943,515 | 30,739,746 |

| Overall Energy Consumption (GJ) | 32,571,115 | 30,302,683 | 35,143,709 | 32,046,977 |

Energy Intensity (GJ / Crore INR)

Hisar Facility

Jajpur Facility

Both Hisar and Jajpur facilities exceeded their emission reduction targets, demonstrating strong performance in energy efficiency and sustainability. In PAT Cycle II, JSL set ambitious SEC targets as part of its commitment to reducing greenhouse gas emissions. The Hisar and Jajpur plants successfully surpassed their respective targets, resulting in the generation of 20,887 ESCerts.

JSL Super Steel Partners with Sunsure Energy to source Renewable Power

JSL Super Steel, a subsidiary of the company, has signed a Power Purchase Agreement (PPA) with Sunsure Energy to procure 11 MWp of solar power from Sunsure’s 49 MWp solar plant located in Augasi, Uttar Pradesh. This clean energy will meet approximately 40% of JSL Super Steel’s total power needs, supporting both the Uttar Pradesh State Power Banking Policy and the state’s broader push for sustainable energy practices.

The agreement is expected to generate around 16.5 million units of renewable electricity annually, enabling the company to offset nearly 12 million kilograms of carbon emissions each year, equivalent to planting more than 5,45,000 trees.

This initiative is part of Jindal Stainless’s broader sustainability roadmap, which includes a goal to cut carbon emissions by 50% by 2035 and achieve net-zero emissions by 2050.

SCALING ROOFTOP AND FLOATING SOLAR TO POWER SUSTAINABLE OPERATIONS

JSL has commissioned Odisha’s largest captive solar energy plant at its Jajpur facility, developed in partnership with AB Energia Solutions. With a combined capacity of over 30 MWp, the installation includes a 7.3 MWp floating solar plant and a 23 MWp rooftop system across ten industrial roofs. Together, they will generate around 44.3 million units of clean electricity annually, reduce dependency on grid power, and cut CO2 emissions by 32,208 tonnes each year.

By transforming unused rooftops and water bodies into productive clean energy assets, Jindal Stainless is accelerating its journey toward net-zero emissions.

Sustainable Mobility

and Operational Efficiency Initiatives

In FY25, JSL advanced its commitment to sustainable operations by adopting electric forklifts for internal material movement, significantly reducing the company’s dependence on fossil fuels and enhancing energy efficiency. To support low-carbon employee commuting, the company deployed 40 CNG buses and is actively exploring additional green mobility options. JSL’s operational fleet was further strengthened with the integration of three electric forklifts and one electric sweeper. Additionally, the company’s Hisar facility expanded its electric vehicle usage with the deployment of four EVs, reinforcing its efforts toward a cleaner, more energy-efficient future.

Tracking the Emission Journey So Far

Emissions from all operational units are calculated using methodologies outlined in the World Resources Institute–World Business Council for Sustainable Development (WRI–WBCSD) GHG Protocol and ISO 14064:2006 – Part 1. The reported data is subjected to independent third-party assurance annually, as per the International Standard on Assurance Engagements (ISAE) 3410 and ISAE 3000 standards, ensuring reliability and integrity in JSL’s disclosures.

GHG Inventorisation and Intensity – Hisar (tCO2e/tcs)

| Parameter | FY22 | FY23 | FY24 | FY25 |

|---|---|---|---|---|

| GHG Emission (Scope 1) | 2,69,142 | 2,41,731 | 2,57,138 | 2,40,832 |

| GHG Emission (Scope 2) | 5,71,485 | 5,10,878 | 5,42,585 | 4,18,898 |

| GHG Emission (Scope 3) | - | 8,82,934 | 9,70,607 | 13,65,779 |

| GHG Emission Intensity (Scope 1 and 2) | 1.17 | 1.27 | 1.26 | 0.96 |

| GHG Emission Intensity (Scope 3) | - | 1.49 | 1.53 | 1.99 |

GHG Inventorisation and Intensity – Jajpur (tCO2e/tcs)

| Parameter | FY22 | FY23 | FY24 | FY25 |

|---|---|---|---|---|

| GHG Emission (Scope 1) | 25,22,648.5 | 22,68,844.43 | 27,01,047.91 | 27,54,782 |

| GHG Emission (Scope 2) | 79,704.5 | 1,42,112.46 | 1,71,563.93 | 2,00,293 |

| GHG Emission (Scope 3) | - | 18,61,283 | 23,74,836 | 18,46,540 |

| GHG Emission Intensity (Scope 1 and 2) | 2.47 | 2.44 | 2.55 | 2.32 |

| GHG Emission Intensity (Scope 3) | - | 1.89 | 2.11 | 1.45 |

GHG Inventorisation and Intensity: JSL (Standalone)- Jajpur, Hisar, Sukinda, Corporate Office

| Parameter | FY22 | FY23 | FY24 | FY25 |

|---|---|---|---|---|

| GHG Emission (Scope 1) | 28,16,979 | 25,48,227 | 29,92,334 | 29,95,799 |

| GHG Emission (Scope 2) | 6,84,949 | 7,35,756 | 7,87,141 | 6,22,511 |

| GHG Emission (Scope 3) | - | 32,83,983 | 33,45,443 | 32,16,693 |

| GHG Emission Intensity (Scope 1 and 2) | 1.98 | 2.08 | 2.15 | 1.85 |

| GHG Emission Intensity (Scope 3) | - | 1.76 | 1.90 | 1.64 |

GHG Inventorisation and Intensity: JSL Subsidiaries- JUSL, JSL SSL, JSSL, and Chromeni Steels Limited (CSL)

| Parameter | FY24 | FY25 | |||||

|---|---|---|---|---|---|---|---|

| JUSL | JSL SSL | JSSL | JUSL | JSL SSL | JSSL | CSL | |

| GHG Emission (Scope 1) | 1,52,470.04 | 9,529.39 | 334.03 | 1,75,112 | 12,414 | 340 | 5,933 |

| GHG Emission (Scope 2) | 1,96,049 | 13,663 | 2,970 | 1,89,452 | 20,691 | 3,233 | 16,581 |

| GHG Emission (Scope 3) | - | - | - | 2,34,507 | 15,336 | 23,534 | 5,585 |

- JUSL - Jindal United Steel Limited

- JSSL - Jindal Stainless Steelway Limited (Gurgaon, Pathredi, Chennai, Vadodara, Mumbai)

- JSL SSL - JSL Super Steel Limited

- CSL - Chromeni Steels Limited

Continuous Emission Monitoring Systems (CEMS)

Maintaining air quality by keeping emissions of particulate matter (PM), nitrogen oxides (NOx), and sulphur oxides (SOx) within permissible limits is essential to safeguard the health and well-being of the company’s employees, contractors, suppliers, and surrounding communities. Beyond environmental and health considerations, failure to comply with emission norms could lead to regulatory penalties, operational interruptions, and reputational risks. At JSL, robust air emissions management is integrated across the operational lifecycle. Continuous monitoring systems and proactive control measures are in place to ensure regulatory compliance and transparent reporting. JSL’s air emissions management system includes:

- A mobile application for real-time emissions tracking

- Dust suppression sprinklers to minimise fugitive emissions

- Online ambient air quality assessments

- Deployment of state-of-the-art Air Pollution Control Devices (APCDs) across key facilities

At the Jajpur facility, targeted improvements such as ammonia dosing optimisation and bag filter upgrades in the Steel Melting Shop (SMS) and Ferro Alloy units are further helping reduce dust and CPP emissions.

Air Emissions for FY25 (MT)

Recognising Excellence in Environmental Stewardship

Hydrogen

Leadership Award

Awarded by the Economic Times for pioneering technologies and renewable energy initiatives driving green growth

Special Recognition – ET Energy Leadership Award 2024

Awarded by The Economic Times for innovation- led contributions to sustainable development

Global Environment

Award 2024

By Energy and Environment Foundation for outstanding achievements in Green Hydrogen and Energy Efficiency

IATF 16949:2016

Certification

Recognised for excellence in quality management systems in the automotive sector (certified by TUV Rheinland)

Water and Wastewater Management

Water is a critical input for JSL’s operations, especially given the location of its Hisar plant in Haryana, a region designated as water-stressed by the Central Ground Water Board (CGWB). The company has adopted a structured water management approach grounded in the principles of Reduce, Reuse, Recycle, and Recover. The focus is on minimising freshwater withdrawal by maximising the internal reuse of treated effluents through the deployment of the best available technologies.

Further, JSL has undertaken water conservation initiatives across all plant sites, including rainwater harvesting systems, Zero Liquid Discharge (ZLD) infrastructure, and advanced wastewater treatment solutions. In FY25, a total of 410,855 m3 of rainwater was harvested at the Hisar and Jajpur facilities. Also, the company conducts water risk assessment to help monitor usage patterns, minimise losses, and identify new opportunities for efficiency and savings. JSL provides awareness training to employees as part of its water efficiency management programmes.

| Parameter | FY22 | FY23 | FY24 | FY25 |

|---|---|---|---|---|

| Total volume of water withdrawal (in kilolitres) | 1,16,90,426 | 1,16,70,159 | 1,33,20,439 | 1,50,77,894 |

| Total volume of water consumption (in kilolitres) | 1,16,90,426 | 1,11,90,622 | 1,27,72,873 | 1,44,11,834 |

Water Risk Assessment

The water risk assessment conducted for JSL’s operational sites, i.e., Hisar and Jajpur, comprehensively considers both dependency-related and impact-related water risks:

Dependency-related risks

- Both sites rely on a single water source – Hisar on the Balsamandh Canal (Western Yamuna Canal) and Jajpur on the Brahmani River.

- There are no alternate water sources available, making operations vulnerable to supply disruptions.

- Infrastructure risks such as sand ingress, pump damage, and pipeline maintenance are acknowledged.

Impact-related risks:

- Water quality degradation due to upstream pollution (e.g., industrial effluents, untreated wastewater).

- Flooding and drought risks are significant, with historical events impacting Hisar and potential threats identified for Jajpur.

- Community-level sanitation gaps may lead to contamination of local water bodies.

JSL’s assessment incorporates forward-looking and stakeholder- sensitive aspects, including future projections of water availability and an evaluation of potential water stress for key locations, utilising established analytical tools. It also addresses water quality concerns, considering factors such as intake source pollution and possible contamination from regional industrial activities. Impacts on local communities are reviewed, with attention to disparities in access to safe drinking water and potential effects on water resources due to gaps in WASH infrastructure. Additionally, the assessment considers possible changes in local regulatory frameworks, emphasising ongoing engagement with relevant water authorities and the need to monitor evolving policies and regulations.

Water Management Policy

JSL’s Water Management Policy sets out a clear and company-wide commitment to sustainable water use. It covers all stakeholders – employees, contractors, suppliers, and customers and aims to reduce water withdrawal, ensure 100% recycling, and support Zero Liquid Discharge across its operations. The policy goes beyond compliance by aligning with UN Sustainable Development Goal 6 and adopting best practices from the steel industry. It also focuses on restoring nearby water bodies through nature-based solutions and ensuring access to safe drinking water and sanitation (WASH) in the workplace and neighbouring communities. The policy promotes regular water audits, monitoring of water quantity and quality, and public disclosure of performance. It encourages collaboration with local communities and academic institutions while building awareness among employees and partners.

Implementation of ZLD System

JSL has implemented closed- loop cooling systems across its manufacturing sites to minimise freshwater usage and support its Zero Liquid Discharge (ZLD) commitment. Cooling tower blowdown water is treated through skimming tanks, oil separation units, and reverse osmosis systems, and is then reused in critical operations. This treated water is also used in utility processes like dust suppression and firefighting. By maintaining a cycles-of-concentration of around six, the company ensures that more water is recirculated within the system, reducing overall water withdrawal. In addition, treated sewage from on-site sewage treatment plants is repurposed for horticulture and other non-process uses. These measures align with JSL’s ISO 14001-certified environmental management systems.

Internal Water Pricing (IWP)

JSL is committed to responsible water stewardship and the sustainable management of water resources across all operations. In support of this commitment, the internal price of water was assessed for the company’s operations. The company collected detailed data for FY23 and FY24 from its two largest manufacturing facilities, covering production volumes, water withdrawal, procurement costs, and incoming water quality. Both facilities primarily depend on surface water, with procurement costs ranging from INR 8.30/m3 to INR 20/m3. To evaluate the financial implications of water-related risks, the company used the Water Risk Monetiser – a tool developed by Ecolab, Trucost, and Microsoft. This tool monetises water scarcity by factoring in both availability and quality. It considers site-specific variables such as local water availability, facility demand, competition among water users, and the broader impact of withdrawals on the surrounding watershed. The tool also incorporates historical pricing trends and future projections in production and water demand. Based on this analysis, the estimated water cost – adjusted for risk – over the next 10 years is projected to range from INR 21/m3 to INR 47/m3 for JSL.

Circular Economy and Waste Management

By prioritising resource efficiency, reusing materials, and minimising waste generation, JSL aims to reduce its environmental footprint. The company is dedicated to advancing the principles of a circular economy through effective waste management strategies.

JSL’s approach to circular economy is rooted in resource efficiency, waste reduction, and material recovery. Approximately 72% of the company’s raw material input comprises high- quality recycled scrap, significantly reducing its reliance on virgin resources and lowering carbon emissions. The company further strengthens circularity by recovering valuable metals from by-products such as grinding dust, mill scale, quench scale, and EAF residues. These materials are processed into briquettes and reintegrated into production via Submerged Arc Furnaces (SAF).

Fly ash from captive power plants is reused in cement and brick manufacturing, while bottom ash is deployed for land restoration. Additional waste streams such as mill scale, bag filter dust, interleaving paper, plastic waste, and neutralised cake are recycled internally or repurposed, reducing landfill dependency. Ferroalloy SAF slag is processed at jigging plants for metal recovery and later used in construction, further closing the material loop.

Stainless steel production at Jindal Stainless primarily uses Electric Arc Furnaces (EAF), powered by electricity with scrap as primary raw material, making the process inherently low- carbon and 100% recyclable.

JSL has established an advanced metal recovery facility at its Jajpur site to extract valuable metals from ferrochrome and SMS slag. This process enables the reuse of recovered metals within its stainless steel manufacturing cycle, reducing reliance on virgin raw materials and minimising the environmental impact associated with traditional slag disposal.

By reintegrating recovered materials into production, the facility supports a closed-loop system and strengthens circularity across the company’s operations. In FY25, 29,144.53 MT of metal were recovered from the HARSSCO plant in Jajpur and reused in steelmaking. Additionally, 3,08,336.9 MT of ferrochrome slag were repurposed during the year, further contributing to resource efficiency and waste reduction.

JSL is committed to Extended Producer Responsibility (EPR) in line with MoEF&CC regulations. The company’s Jajpur unit, registered with the CPCB, complies with EPR obligations under the Plastic Waste Management Rules, 2016, as a Brand Owner and Importer. All plastic waste is responsibly managed and directed to authorised recyclers registered under the Extended Producer Responsibility (EPR) programme with the Central Pollution Control Board (CPCB).

Transition to Bulk Acid Supply to reduce Plastic Waste

To reduce plastic waste generated from acid supply, which was previously delivered in 50- and 200-litre plastic drums, JSL has strategically transitioned to bulk procurement. Currently, 20–25% of the company’s acid consumption is supplied via 10 KL and 20 KL bulk tankers, eliminating the use of plastic drums at these volumes. This shift has significantly reduced single-use plastic waste, improved operational efficiency and safety in acid handling, and supports the company’s broader waste minimisation and sustainability objectives. This initiative marks a key advancement in resource optimisation and responsible chemical management within its operations.

Sustainable Improvement in Coil Handling – Replacement of Wooden Pallets with MS Supports

JSL Hisar has enhanced its internal coil handling by replacing wooden pallets with custom-fabricated Mild Steel (MS) supports on its truck fleet. This eco-friendly modification eliminates wood usage, reducing solid waste from damaged pallets, while improving safety, structural stability, and reusability during internal coil transfers. This initiative aligns with the company’s sustainability goals and continuous improvement efforts within plant operations.

In FY25, the total waste generated amounted to approximately 1.95 million metric tonnes (MT). The volume of waste recycled or reused exceeded the total waste generated, reaching over 2.01 million MT, reflecting the inclusion of legacy waste or carryover from previous years. Meanwhile, waste sent to landfills remained minimal at approximately 42,852 MT of non-hazardous waste at its Jajpur facility, underscoring the company’s continued commitment to sustainable waste management and circular economy practices.

To promote sustainable practices within the plant, JSL regularly conducts training and awareness programmes focused on the safe handling and management of hazardous and non- hazardous waste. These sessions cover key topics such as the identification and segregation of waste types, proper colour-coding and labelling of waste bins, and compliance with Waste Management Rules for handling and disposal. Emphasis is also placed on implementing the 3Rs – reduce, reuse, and recycle – within the workplace, along with strategies to minimise waste generation at the source. In addition to monthly training sessions, the company organises special awareness drives on significant environmental occasions such as World Environment Day, Earth Day, and World Environment Health Day. These drives include poster competitions, pledge campaigns, and interactive activities to engage employees and reinforce the importance of environmental stewardship.

Waste Management Approach and Roadmap

A comprehensive baseline waste assessment is undertaken to identify current waste generation patterns and key sources. Building on these insights, a structured waste reduction programme is implemented to minimise waste at its origin. Concurrently, recycling initiatives are expanded to maximise material recovery and diversion from landfill. The overarching goal is to achieve ‘Zero-Waste-to-Landfill’ certification from an accredited third party by 2030, demonstrating a commitment to sustainable resource management and environmental stewardship.

Tailings Management

Jindal Stainless has established a comprehensive Tailings Management Policy applicable to its owned & operated Tailing Storage Facilities (TSFs) at Kaliapani, to ensure the safe, sustainable, and compliant handling of tailings generated during mineral processing operations. The policy is aligned with global standards such as the Global Industry Standard on Tailings Management (GISTM), UN Guiding Principles on Business & Human Rights and other leading national/international best practices, reflecting the company’s commitment to environmental stewardship and operational excellence.

Tailings from the processing plant are treated through a multi-stage process that includes screening, hydrocycloning, and flotation to recover valuable materials such as chromite. The treated sludge is recycled within the system to optimise resource utilisation, while residual tailings are securely stored in engineered tailing ponds. These ponds are lined with high-density polyethylene (HDPE) sheets to prevent seepage and protect surrounding ecosystems.

Environmental safeguards are integral to the management approach. Continuous monitoring and periodic removal of tailings ensure the structural integrity and safety of storage facilities. Dust emissions are controlled through sprinkler systems, and water used in processing is largely recycled from tailing ponds, supporting a zero-discharge policy with minimal freshwater intake. The company has one planned facility currently under construction. The potential risk associated with this tailings facility is considered low due to minimal environmental and social impacts, which can be effectively managed within its existing capabilities in accordance with GISTM and ICMM guidelines.

End-to-End Tailings Management Process

Evaluate existing tailings storage facilities for structural integrity, environmental risks, and compliance with safety standards. This includes site inspections, monitoring systems, and risk

Create a comprehensive plan outlining tailings handling, treatment, storage, and monitoring strategies. The plan should align with regulatory requirements and sustainability goals.

Apply technologies and operational practices to reduce tailings volume and toxicity. This may include material recovery (e.g., chromite), recycling, and process optimisation.

Integrate tailings management into the broader mine closure strategy. Ensure safe decommissioning of tailings facilities, long-term monitoring, and rehabilitation of the post- mining landscape.

| Facility Status | Number of Facilities | Number of Facilities categorised as ‘high risk potential’ (‘extreme’ and ‘very high’) | Percentage of ‘high risk potential’ sites |

|---|---|---|---|

| Active Facilities | 1 | 0 | 0 |

| Inactive Facilities (Care & Maintenance / Closed) |

0 | 0 | 0 |

| Planned Facilities | 1 | 0 | 0 |

Mine Closure Plan (MCP)

The MCP explicitly states that closure planning is integrated from the project’s feasibility stage through the life of mine (LoM), ensuring alignment with end- of-life and post-closure objectives. It is reviewed at least every five years or upon significant operational changes, regulatory amendments, or new EIA/ SIA findings, with stakeholder input considered. JSL’s plan includes the performance targets covering areas like mine design, socio-economic development, rehabilitation, post- mining land use, and biodiversity. These targets are developed in consultation with stakeholders, including local communities and authorities. The company emphasises the progressive rehabilitation during operations. Activities such as slope grading and revegetation are implemented concurrently to reduce end-of-life liabilities and promote ecological recovery and adaptive management, allowing for the incorporation of new technologies and evolving site conditions. The company monitors its post-closure and includes annual updates to the Closure Execution Plan (CEP), which includes cost estimates. This ensures that closure liabilities are regularly reviewed and remain aligned with environmental and social performance expectations.

Biodiversity

JSL recognises the critical importance of biodiversity in maintaining ecological balance. The company is committed to minimising its impact on natural habitats through responsible land use, conservation efforts, and sustainable sourcing practices. Its initiatives are designed to protect and enhance biodiversity, contributing to the preservation of ecosystems for future generations. JSL’s facilities are not situated around any ecologically sensitive areas (such as national parks, wildlife sanctuaries, biosphere reserves, wetlands, biodiversity hotspots, forests or coastal regulation zones). Jindal Stainless has a standalone Biodiversity Policy in alignment with the Kunming- Montreal Global Biodiversity Framework and TNFD guidelines, which reflects its commitment to minimising these impacts, conserving biodiversity, and promoting ecosystem health. This policy applies to the company and its affiliated companies, including employees, contractors, consultants, suppliers, service providers, and customers.

Biodiversity Risk Assessment (BRA)

JSL conducted the Biodiversity Risk Assessments (BRA) for its operations in Jajpur and Hisar and developed site-specific Biodiversity Management Plans. These plans are based on the AR3T framework: Avoid, Reduce, Restore, Regenerate, Transform, and guide the company’s efforts in responsible land use, reforestation, and ecological restoration. Building on this foundation, the company is now extending these assessments across its value chain, with a focus on understanding dependencies, risks, and opportunities involving key suppliers and customers. As part of its commitment to achieving No Net Loss (NNL) in biodiversity, JSL has initiated efforts to control and manage invasive species within its operational areas and surrounding buffer zones.

Further, the company’s strategy includes identifying native species and their habitats through field research and implementing conservation actions to protect them. JSL assesses biodiversity risks across the entire project lifecycle, including decommissioning and rehabilitation, and is now extending these evaluations to its value chain, involving key suppliers and customers to identify shared risks and opportunities. The company also engages in ongoing plantation drives to preserve and enhance green cover around its operations. Looking ahead, JSL aims to develop science-based targets for nature (SBTn) to further align its goals with global biodiversity benchmarks. Biodiversity performance is reviewed regularly and disclosed annually to promote transparency, accountability, and continuous improvement in its environmental stewardship.

Moreover, JSL has implemented significant initiatives to enhance green cover and promote ecological sustainability, aligning with its commitment to balance operational growth with environmental stewardship. The company’s focus on large- scale plantation efforts supports carbon sequestration, aids climate change mitigation, and offsets operational emissions.

JSL’s afforestation activities contribute to soil conservation, fertility improvement, and groundwater recharge, delivering tangible benefits to the local environment and communities. Approximately 89,000 saplings have been planted to date.

| Facility Status | Number of Sites | Area (Hectares) |

|---|---|---|

| Overall Total number and total area of the company’s operational sites |

2 | 448.10 |

| Assessment Biodiversity impact assessments conducted |

2 | 448.10 |

| Exposure Sites having significant biodiversity impact, or are in proximity to critical biodiversity |

2 | 448.10 |

| Management plans Sites having a biodiversity management plan |

2 | 448.10 |