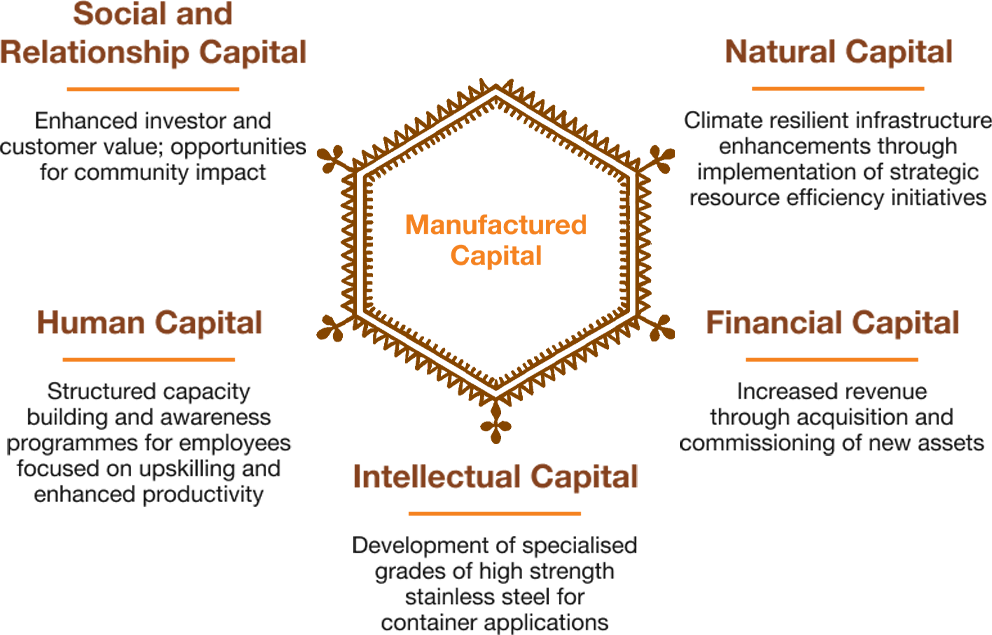

For Jindal Stainless, manufacturing capital is the enduring anchor of its operational prowess and a critical enabler of sustainable growth. It directly underpins the company’s capacity to meet customer demands, sharpen its global competitive edge, and scale its operations responsibly. The company is unwavering in its commitment to continuous investment in, and modernisation of, its world-class infrastructure, ensuring consistent delivery of high-quality, efficient, and environmentally conscious stainless steel. This strategic focus on advanced manufacturing not only optimises JSL’s output but also embeds sustainability into the very core of its production lifecycle.

JSL’s Operations

JSL’s manufacturing capital underpins its capacity to serve customers, compete globally, and scale sustainably. The company has consistently developed and modernised advanced infrastructure to support the high-quality, efficient, and low-impact production of stainless steel. JSL’s current operational production capacity stands at 3 MTPA, and the company has defined a roadmap for expansion to 4.2 MTPA. With 16 facilities across India, Spain, and Indonesia (as of FY25), its manufacturing footprint strategically positions it to serve domestic and global markets with agility and reliability.

Furthermore, the company’s operations are centred on advanced manufacturing. Its facilities are integrated with IoT platforms, AI/ML-driven analytics, and enterprise-wide digital systems such as SAP S/4HANA Cloud, driving precision, reducing downtime, and improving overall productivity. Moreover, these technologies are crucial in enhancing traceability, reducing energy consumption, and ensuring consistent product quality.

JSL’s capability to manufacture over 120 diverse stainless steel grades enables it to meet the evolving demands of customers across sectors such as transportation, construction, infrastructure, nuclear energy, and space exploration. Throughout the year, the company supplied stainless steel for enterprises like the Vande Bharat Metro, defence projects, and electric buses, reinforcing its position as a trusted partner in India’s development and innovation landscape. Also, Jindal Stainless continues to focus on lightweight stainless applications, hydrogen-compatible alloys, and high-nitrogen steel (HNS) products that cater to emerging technologies and clean energy systems.

Gurugram Corporate Office (Platinum)

This office has earned the highest level of LEED certification, Platinum, under the LEED v4.1 Operations and Maintenance: Existing Buildings rating system, reinforcing JSL’s sustainability goals.

Jajpur Clubhouse (Gold)

The Jajpur Clubhouse has been awarded a Gold

certification under

the

LEED v4.1 rating system.

Strengthening Capabilities

Through Strategic Acquisition

JSL continued to strengthen its manufacturing capabilities and market position through a significant strategic development during the reporting period. The company successfully acquired the remaining 46 per cent stake in Chromeni Steels Limited (CSL) for a consideration of INR 278 crore. This transaction was completed with effect from June 15, 2024, at which point CSL became a wholly owned subsidiary of the company.

This acquisition marked a pivotal moment in the company’s growth trajectory. The investment in CSL was a strategic move to expand the company’s cold rolling capacities, particularly to cater to the growing demand for stainless steel in India. By acquiring full ownership, the company fully integrated CSL’s operations, thereby unlocking significant synergies and enhancing JSL’s operational efficiency across the value chain. This complete integration has optimised the company’s production planning, streamlined logistics, and provided greater flexibility in serving its diverse customer base.

The facility at Mundra, Gujarat, which was part of CSL, is a modern cold rolling plant with a capacity of 0.6 MTPA. This state-of-the-art facility is strategically located near the Mundra Port, offering distinct logistical advantages for both raw material imports and finished goods exports. Its advanced infrastructure complements the company’s existing capacities and bolsters its ability to meet increasing demand for flat stainless steel products, particularly in high-growth segments such as consumer durables, architecture, building and construction (ABC), and pipes and tubes.

This strategic move aligned with JSL’s long-term vision of sustainable growth and market leadership. It enhanced its production capabilities, strengthened its supply chain resilience, and allowed the company to further solidify its presence in key domestic and international markets. The full ownership of CSL reinforced the company’s commitment to expanding its footprint and delivering superior quality stainless steel solutions.

Securing Critical Raw Materials

Through Global

Backward Integration

JSL’s commitment to operational resilience and strategic raw material security led to a significant milestone in the reporting period with the successful commissioning of its Nickel Pig Iron (NPI) plant in Indonesia. This state-of-the-art facility, established through a joint venture with New Yaking Pte. Ltd., commenced operations eight months ahead of its original schedule, underscoring the company’s efficient project execution and strong collaborative partnerships.

Located in an industrial park on the Halmahera Islands, Indonesia, the NPI plant represents a crucial backward integration strategy for JSL’s operations. The company holds a 49% equity stake in this joint venture, having invested approximately USD 157 million in the project. The facility possesses an annual nameplate production capacity of up to 2,00,000 metric tonnes of NPI, containing an average of 14% nickel content. This substantial capacity is designed to ensure a consistent and reliable supply of nickel, a vital raw material for stainless steel production, which is not readily available from domestic sources in India.

Securing a long-term, captive supply of NPI directly addresses the volatility often observed in global nickel prices and supply chains, which can be influenced by geopolitical factors and logistical challenges. By establishing this facility, the company has enhanced its raw material security and strengthened its cost competitiveness, safeguarding its margins against market fluctuations. This strategic investment also marked a pioneering step for an Indian company in securing a direct stake in overseas nickel reserves.

The early commissioning of the NPI plant has already enabled operations at approximately 65% utilisation within the reporting period, demonstrating immediate benefits. This initiative is a testament to JSL’s proactive approach to managing key inputs and its dedication to building a robust and resilient supply chain for its global stainless steel operations. Commercial production from the facility is expected to ramp up further, continuing to augment the company’s raw material independence.