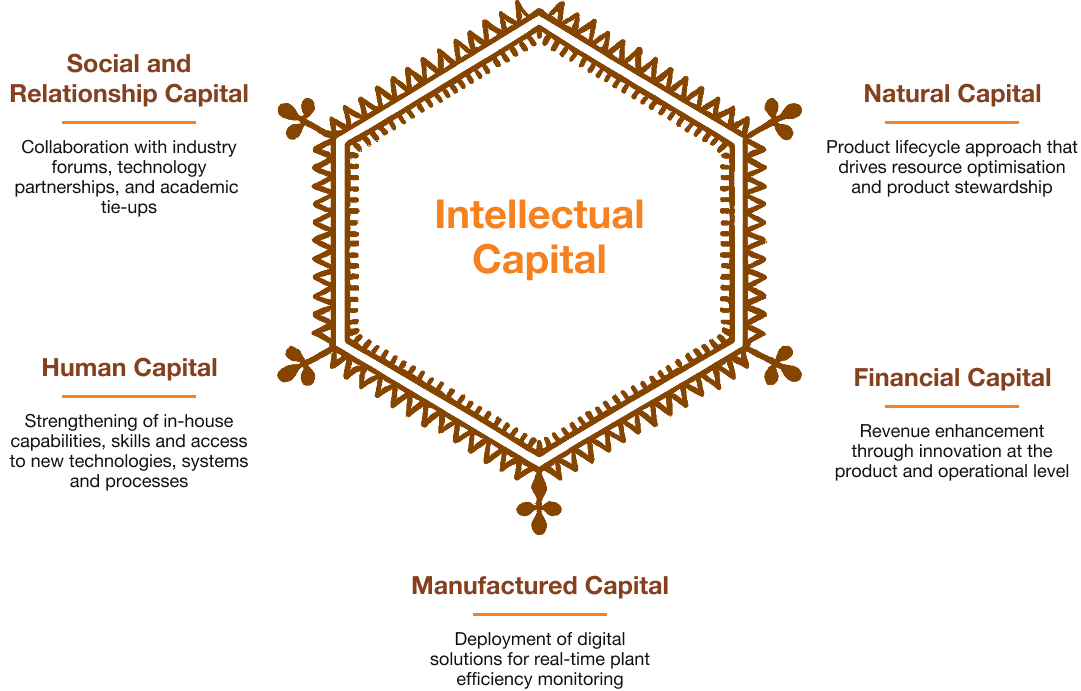

Managing intellectual capital is a key enabler in maintaining Jindal Stainless’ competitive advantage. In a market defined by rapid technological evolution and shifting stakeholder expectations, the company’s ability to innovate across products, processes, and platforms is central to how JSL differentiates and delivers value.

The company continues to target investments in research and development, focusing on advanced material science, metallurgical innovations, and process efficiencies. Collaborations with leading institutions such as IIT Bombay and organisations like DRDO enhance its in-house R&D capabilities, enabling it to co-develop high-performance stainless steel solutions for strategic sectors.

Throughout the year, JSL strengthened its product portfolio with innovations such as hydrogen-ready stainless steel, lightweight clad plates, and high-nitrogen steel (HNS) for clean energy and infrastructure applications. The company’s portfolio of over 120 stainless grades serves a wide range of industries from defence and aerospace to mobility and nuclear, where durability, safety, and reliability are critical. The company is also making advancements in digital transformation. The deployment of SAP S/4HANA Cloud, integration of blockchain-enabled paperless trade systems, and use of AI/ML for process optimisation streamlines operations, reduces transaction times, and improves responsiveness across the value chain. In FY25, JSL directed 51.98% of its total R&D investments and 11.33% of its total capital expenditure towards technologies aimed at improving the environmental and social impacts of its products and processes. These investments contributed to key developments such as import-substituting Nickel alloy clad plates, corrosion-resistant 410L rebars for marine applications, and localised 415-grade stainless steel to reduce transport emissions.

The Promise of AI

Today, artificial intelligence (AI) is synonymous with convenience. This programmed convenience has comfortably woven its place in India’s manufacturing sector. It is now a core component of the Industry 4.0 movement, aka the Fourth Industrial Revolution. For the manufacturing sector, AI embeds digital technologies into manufacturing processes and builds smart factories that seamlessly synchronise digital and physical systems. As India stands on the brink of a smart manufacturing revolution, streamlining excellence, sustainability, and efficiency is well within the manufacturers’ reach – thanks to AI. In the case of stainless steel, AI has huge potential – waiting to be explored – for innovation, invention, and revolution. Here’s JSL’s take on leveraging AI to maintain industry competitiveness in the global market and render it safer, smarter, and more sustainable.

Optimising at Speed

Optimising manufacturing processes entails enabling alterations and adjustments to production metrics, ensuring enhanced efficiency, and administering predictive maintenance to reduce downtime. However, this requires collecting and analysing a humongous data volume. AI can deliver this in real-time without compromising on speed and precision. The time thus saved can be directed to strategising, innovating, and change-making, thereby bringing in more profits. As per an Accenture report, the manufacturing sector is likely to witness a 45% increase in revenue by 2035, driven by AI adoption.

Seamless Production and Optimal Quality

Automation presents the risks of unexpected breakdowns, particularly when a company is vying to achieve its production targets. Earlier, there was a lack of prediction models. Instead, the sector relied on manual inspections, which accounted for human error, and, therefore, were not 100% accurate. In this regard, AI brings anomaly detection and data analytics to the table.

Through a digital twin – the virtual depiction of any system or object – simulating situations and outcomes becomes possible. This further ensures a seamless production process, a more robust supply chain, and an increased machinery lifespan. Similarly, optimal quality can be ensured with the adoption of the Internet of Things (IoT), robotics, machine learning (ML), and AI, thereby reducing the wastage of raw materials.

Digitalisation and Technology Integration

JSL has rapidly advanced its digital transformation under Industry 4.0, deploying powerful technology enablers across operations. In collaboration with Capgemini, the company conducted workshops and interviews to diagnose challenges and develop a strategic roadmap featuring 40 high-impact digital use cases, aligned with World Class Manufacturing pillars, to build true smart plants. Procurement and supplier interactions are streamlined via SAP ARIBA and AI-powered chatbots, ensuring transparency and efficient stakeholder collaboration. Additionally, the company has been recognised with the QuPID Digital Transformation Award, underscoring its leadership in digital innovation.

LEVERAGING SAP S/4HANA AND AI FOR ENHANCED PLANT EFFICIENCY

JSL has significantly enhanced plant efficiency and operational agility by migrating to SAP S/4HANA under the ‘Rise with SAP’ framework and integrating AI-driven tools. This transformation is part of a broader Industry 4.0 initiative, co-developed with Capgemini, which prioritised 40 digital use cases aligned with World Class Manufacturing standards. At the Jajpur and Hisar facilities, SAP-enabled systems are now integrated with logistics platforms such as Vaahan, Saarathi, ULIP, and FASTag, helping minimise errors and streamline data flow.

JSL’s journey toward AI-led plant efficiency began with the implementation of Digital Shopfloor and Digital Control Tower initiatives at Jajpur and Hisar. The Digital Shopfloor integrates IoT devices to collect real-time data on operations, maintenance, and quality parameters through edge and cloud platforms. This transition has eliminated fragmented system entries and paper logs, creating a unified, paperless platform. Complementing this, the cloud-based Digital Control Tower consolidates data and provides real-time dashboards for monitoring machine health, quality, and operational KPIs. As the platform evolves, it will support predictive and prescriptive analytics, enabling system-driven decision-making across functions.

These initiatives are geared towards improving key performance metrics such as Overall Equipment Effectiveness (OEE), Mean Time to Repair (MTTR), Mean Time Between Failures (MTBF), quality, turnaround time, and cost. With a strong digital foundation, JSL is now expanding AI and Generative AI across business functions to further boost efficiency, agility, and long-term operational excellence.

INNOVATION, R&D, DIGITALISATION, AND KNOWLEDGE PARTNERSHIPS

Innovation at Jindal Stainless is fuelled by a strong foundation in research, collaboration, and digital transformation. The company’s in-house R&D team has led significant advancements, including the development of indigenous hot-roll bonded clad plates, which contribute to technological self-reliance and sustainability goals. Complementing its internal efforts, Jindal Stainless has built robust partnerships with academic institutions such as IIT Kharagpur, focusing on joint research in metallurgical process optimisation, alloy development, and materials characterisation. It has also instituted a Chair Professorship at IIT Bombay to strengthen research and curriculum around stainless steel technologies.

Project

Pragati:

Digitalising Supply Chain for a

Sustainable Manufacturing Ecosystem

Jindal Stainless launched Project Pragati at its Hisar manufacturing unit, as part of its ongoing efforts to automate the production process, from casting to finishing. It is unprecedented in the steel and stainless steel industries, and marks a significant milestone in JSL’s journey to optimising its value chain through digital innovation. With Capgemini as the implementation partner, it is set to unfold in multiple phases. Pragati integrates advanced planning and execution technologies through Dassault Systèmes’ Delmia applications to enhance productivity and customer experience. Project Pragati offers a glimpse into how virtual twins and digital manufacturing technologies can revamp traditional industries at scale. Overall, this collaboration will reinforce the supply chain agility and operational excellence, and help pursue India’s vision of a tech-enabled, self-sustaining industrial ecosystem.

10–15% reduction in customer lead times to boost delivery performance

Inventory optimisation using off-take trend analysis

8–10% savings in inventory costs through real-time tracking and smart allocation

~5% improvement in capacity utilisation enabled by visibility into equipment loading

Route optimisation to improve logistics and operational efficiency

Product Stewardship

and Innovation

Maximising Recycling to promote Circular Manufacturing

At Jindal Stainless, 72% of scrap and recycled waste is utilised in production, demonstrating the company’s strong commitment to circular economy principles. By maximising the use of scrap and reducing dependence on natural resources, JSL is actively advancing a closed-loop system of production. Stainless steel is uniquely suited for sustainability and can be recycled indefinitely without any loss in quality. The company integrates this advantage into its operations by prioritising recycled inputs and promoting the reuse of industrial by-products, such as scrap metal recovered from slag and grinding dust. Further, the company’s Electric Arc Furnace (EAF) technology is central to this process, efficiently remelting vast quantities of stainless steel scrap to produce new, high-quality stainless steel. This advanced remelting capability enables it to maintain a low-carbon production footprint while ensuring optimal resource utilisation and conservation of raw materials. JSL’s efforts are guided by the principles of reduce, reuse, recycle, recover, and repurpose, which are embedded across the value chain to build a more resource-efficient and sustainable manufacturing process.

CASE STUDY

Pioneering Sustainable Logistics

with High-Strength Stainless Steel Containers

Objective

To revolutionise the logistics industry by introducing high-strength stainless steel as a sustainable, durable, and cost-effective alternative to conventional container materials like mild steel. Jindal Stainless aimed to address key industry challenges such as corrosion, high maintenance costs, and environmental impact, while supporting the ‘Make in India’ initiative and promoting a circular economy.

Implementation

Jindal Stainless undertook a strategic initiative to develop and supply specialised grades of high-strength stainless steel tailored for various container applications, including:

- Dry van containers

- Refrigerated (reefer) containers

- Tank containers

- Railway wagons

- Road tankers

Key steps in the implementation included:

- Material Innovation: Developing stainless steel grades with superior strength-to-weight ratios and corrosion resistance.

- Industry Collaboration: Partnering with container fabricators and logistics companies to customise solutions for specific transportation needs.

- Sustainability Focus: Promoting the recyclability and long service life of stainless steel to reduce environmental impact.

- Infrastructure Development: Supporting domestic manufacturing capabilities aligned with national initiatives like ‘Make in India’.

Outcome

The adoption of high-strength stainless steel containers led to transformative results:

- Extended Lifespan: Containers exhibited exceptional durability, reducing the frequency of repairs and replacements.

- Operational Efficiency: Lighter containers enabled higher payloads and lower fuel consumption, enhancing logistics efficiency.

- Cost Savings: Reduced maintenance and longer service life significantly lowered life cycle costs for logistics operators.

- Environmental Impact: Lower carbon emissions and 100% recyclability contributed to a more sustainable logistics ecosystem.

- Enhanced Safety and Hygiene: Stainless steel’s non-porous surface ensured better hygiene and security, especially for sensitive goods.

This initiative has set a new benchmark in sustainable logistics, reinforcing Jindal Stainless’ leadership in material innovation and environmental stewardship.

Greenified Manufacturing: Custom-engineering Sustainable Logistics

JSL is driving forward the agenda for sustainable logistics in India through a pioneering collaboration with CJ Darcl Logistics Limited (CJ Darcl), one of the nation’s leading integrated logistics providers. This strategic partnership focuses on the development and deployment of lightweight and highly sustainable stainless steel containers, marking a significant advancement in the efficiency and environmental performance of the logistics sector. Traditional carbon steel containers, while widely used, present limitations regarding weight, maintenance, and overall environmental footprint. The collaboration with CJ Darcl directly addresses these challenges by leveraging the superior properties of stainless steel.

For each container fabricated under this initiative, JSL supplied approximately 2.2 metric tonnes of high-strength JT grade stainless steel (also known as N7 as per IS 6911 specifications). This material replaced the conventional carbon steel traditionally used in the sidewalls, end walls, and roof, with customised stainless steel tubes also forming the underframes.

Beyond material supply, the company provided comprehensive technical support throughout the project lifecycle. This included collaboration during the design phase, conducting in-depth Finite Element Analysis (FEA) and Factor of Safety (FOS) analysis, developing Standard Operating Procedures (SOPs) for fabrication, and offering hands-on training to the fabrication team at Kamal Coach Works, CJ Darcl’s approved vendor in Jaipur. This holistic approach ensured the successful fabrication and deployment of the initial 50 stainless steel containers, completed as of September 30, 2024.

This partnership with CJ Darcl exemplifies Jindal Stainless’ commitment to pioneering sustainable and cost-effective solutions that benefit both industry and the environment. It reinforces JSL’s leadership in providing advanced material solutions for a future-ready, greener logistics ecosystem in India.

This transition to stainless steel has yielded substantial benefits:

Aligns with India’s 2070 carbon neutrality vision

Product Carbon Footprint Assessments (Cradle to Gate) for Several Stainless Steel Grades

Jindal Stainless has undertaken Product Carbon Footprint (Cradle-to-Gate) assessments for twelve stainless steel grades, in full compliance with ISO 14040:2006, ISO 14044:2006, and ISO 14067:2018 standards, which together represent a significant portion of the company’s portfolio. These assessments identify greenhouse gas emissions associated with each grade, from raw material sourcing through to the factory gate, enabling analytical insights into emission hotspots within the steel manufacturing value chain. The cradle-to-gate carbon footprint analysis is conducted in-house. This initiative supports product stewardship by helping to inform strategies such as improved material utilisation and optimisation of manufacturing routes. With usage of recycled scrap consistently above 72% of input materials, these footprint assessments reinforce ongoing efforts to reduce carbon emissions in line with the company’s broader sustainability and emissions reduction objectives. This structured approach provides a reliable foundation for measuring and managing the environmental impact of JSL’s products. The study provides insights into the environmental impact of each product throughout its production lifecycle. These stainless steel grades are manufactured at Jajpur and Hisar facilities and are used across a wide range of industries due to their unique mechanical properties, corrosion resistance, and suitability for specific applications. The study helps in understanding the sustainability profile of each grade, which is crucial for industries aiming to reduce their carbon footprint and enhance supply chain transparency. Jindal Stainless enabled long-term cost efficiencies that translated into consistent, sustainable revenue streams.

Key Assessment Steps:

Goal and Scope Definition:

Defined system boundaries, product function, and study parameters

Data Collection

Used standardised tools and databases for accurate data capture

Inventory and Impact Analysis

Ensured data quality, performed mass balance checks, and benchmarked results

Interpretation

Calculated carbon footprint values as per ISO 14067:2018

The Environmental Product Declarations (EPDs) are currently in progress for four products, being developed in accordance with international standards such as ISO 14025 and EN 15804, which ensure transparency and consistency in environmental impact reporting.

*Revenue Generated from the Product/Service

| FY24 (INR Cr) | FY25 (INR Cr) | |

|---|---|---|

| Total Revenue | 38,356.00 | 40,181.68 |

| Sustainable Revenue* | 20,225.12 | 21,581.58 |

- Stainless Steel Grade – 301 (Jajpur)

- Stainless Steel Grade – 304/L (Jajpur)

- Stainless Steel Grade – 316 (Jajpur)

- Stainless Steel Grade – 321 (Jajpur)

- Stainless Steel Grade – 430 (Jajpur)

- Stainless Steel Grade – IRSM (Jajpur)

- Stainless Steel Grade – 409 (Hisar)

- Stainless Steel Grade – 304 (Hisar)

- Stainless Steel Grade – 316 (Hisar)

- Stainless Steel Grade – 321 (Hisar)

- Stainless Steel Grade – 201 (Hisar)

- Stainless Steel Grade – 301 (Hisar)

Green Stainless Steel and CBAM

As part of its stakeholder advocacy, JSL continues to play an active role in shaping India’s sustainability discourse – engaging with industry bodies, policymakers, and standard-setting institutions. The company has contributed to frameworks such as the Green Steel Taxonomy, Carbon Border Adjustment Mechanism (CBAM) readiness discussions, and the development of a National Corrosion Management Policy.

Forging National Strength: JSL’s Certified Contribution to India’s Defence Prowess

Jindal Stainless places a strong emphasis on contributing to India’s strategic self-reliance, especially within the critical defence sector. The company’s expertise in developing and manufacturing advanced stainless steel and specialty alloy sheets positions it as a vital partner in strengthening the nation’s capabilities and fostering the ‘Atmanirbhar Bharat’ vision.

Through its strategic vertical, Jindal Defence and Aerospace (JDA), the company has consistently delivered high-performance materials for mission-critical applications. JDA has supplied stainless steel grade strips for border fencing requirements of the Indian Armed Forces, and low-alloy steel sheets for motor casings in anti-tank guided missiles, enhancing India’s tactical defence infrastructure.

Over the decades, Jindal Stainless has proudly contributed to several prestigious Defence Research and Development Organisation (DRDO) and Indian Space Research Organisation (ISRO) programmes, including the Chandrayaan series, PSLV, GSLV Mk3, nuclear submarine missile systems, missile canisters across various missile platforms, and exhaust unit applications in rockets.

This multifaceted collaboration across sectors underscores JSL’s enduring commitment to innovation, precision, and nation-building. By delivering best-in-class material solutions, Jindal Stainless remains steadfast in its mission to empower India’s defence and space capabilities and contribute meaningfully to a secure, self-reliant future.

JSL’s contributions span a diverse range of critical projects:

-

Chandrayaan-3

Supplied specialised materials for India’s landmark lunar mission

-

PSLV and GSLV Mk3

Contributed critical steel components to launch vehicle success

-

Missile Programmes

Enabled the development of nuclear submarine missile systems and canisters

-

SMART System (Anti-Submarine Warfare)

Delivered 3 mm special alloy steel sheets engineered to endure extreme pressure and temperature during missile- assisted torpedo deployment

Powering Tomorrow’s Commute: JSL’s Critical Role in India’s Vande Metro Revolution

The intellectual capital at Jindal Stainless goes beyond infrastructure – it is the crucible where innovation meets tangible impact. This capability has been evident in JSL’s pivotal contribution to Indian Railways’ visionary Vande Metro project, a testament to the company’s commitment to shaping sustainable urban mobility. This groundbreaking initiative, unveiling India’s first Vande Metro trains, represents a significant leap in enhancing inter-city travel services. JSL is honoured to have supplied the high-strength, tempered 201LN grade of stainless steel for these cutting-edge train sets. This marks a historic first for Indian Railways, as they transition from conventional ferritic stainless steel, embracing a metal that redefines performance. The company’s advanced manufacturing processes and deep metallurgical expertise enabled it to produce panels with a reduced thickness from 3 mm to a mere 2 mm without compromising structural integrity. This seemingly small reduction translates into monumental gains – significantly lighter train cars, leading directly to enhanced energy efficiency and considerable cost savings over the operational lifespan of the rolling stock. Beyond its lightweight properties, the company’s 201LN grade offers superior attributes crucial for modern rail travel. Its exceptional corrosion resistance, combined with higher inherent strength and superior durability, ensures an extended service life even under demanding conditions. Critically, it exhibits best-in-class crash-resistant properties, prioritising passenger safety above all else. For Indian Railways, this strategic material choice by partnering with JSL aligns perfectly with their ambitious Net Zero targets, as the lighter, more energy-efficient car body directly contributes to a reduced carbon footprint for the nation’s transport network. JSL’s involvement in the Vande Metro, a project designed to connect over 120 cities and revolutionise commutes up to 250 km, underscores the company’s ability to meet the rigorous demands of critical infrastructure and actively pioneer the adoption of advanced, sustainable materials that redefine industry benchmarks. This is how Jindal Stainless leverages its manufacturing excellence to build a more connected, efficient, and sustainable future for India.

Fuelling Global Connectivity

with ‘Made in India’

Stainless Steel Wagons

Jindal Stainless had the honour to demonstrate India’s burgeoning manufacturing prowess and its pivotal role in the global supply chain through a landmark export initiative. The company has successfully supplied the specialised stainless steel for 100 ‘Made in India’ freight wagons for Mozambique, a project that truly underscores its nation’s advanced capabilities and its commitment to sustainable infrastructure worldwide. This prestigious export was facilitated from Deendayal Port in Gujarat to the Port of Nacala in Mozambique, with crucial support from the Ministry of Ports, Shipping, and Waterways, Government of India. As of recent reports, 24 of these wagons have already reached Mozambique, 26 are currently awaiting shipment at the port, and the remaining 50 are en route, showcasing a seamless execution of this large-scale international project. JSL’s contribution to this endeavour extends beyond merely supplying material; it is a testament to the company’s resolve to deliver high-quality, advanced products for international markets. This supports its larger objective of enhancing global transportation efficiency and solidifying India’s position as a global manufacturing hub. This project also complements the company’s long-standing legacy of supporting critical railway infrastructure within India, including providing stainless steel for the nation’s first Vande Metro train, the inaugural underwater metro line in Kolkata, and the first train set for the Regional Rapid Transit System (RRTS).

Key Features of Each Wagon

Custom-Engineered

by JRIL

Designed using IRSM 44 grade stainless steel for unmatched durability and corrosion resistance.

63 MT

Payload Capacity

Each tipper-style wagon delivers high load efficiency with reduced tare weight.

4.3 Tonnes of Specialised Steel Per Wagon

Used in floor, sidewalls, and end walls to boost strength and longevity.

Lower Lifecycle Costs and Emissions

Lightweight design ensures better fuel efficiency and reduced carbon footprint.

Recognised for

Manufacturing Excellence

Jindal Stainless’ commitment to continuous improvement, advanced process engineering, and customer-centric product development has earned the company national recognition. These awards reflect JSL’s pursuit of excellence and its ability to deliver high-quality, future-ready solutions, designed to create impact at a global scale.

Data Management

and Disclosures

Jindal Stainless ensures accurate collection, analysis, and reporting of relevant data to support informed decision-making and maintain transparency. The company’s disclosures comply with recognised standards, providing stakeholders with clear and reliable information on its environmental and social performance.

Digitally Driven Sustainability: How JSL streamlines ESG with Smart Tool

Jindal Stainless has taken a major leap in ESG performance management by integrating the Updapt ESG platform into its sustainability framework. This advanced digital solution automates the collection and analysis of key ESG data – such as production volumes, energy consumption, material usage, and carbon emissions – ensuring real-time, accurate, and seamless reporting.

By embedding Updapt into its operational ecosystem, Jindal Stainless has:

- Minimised manual data handling, reducing errors and improving efficiency

- Standardised ESG workflows across departments and reporting cycles

- Enhanced transparency and traceability in greenhouse gas accounting and sustainability disclosures.

The platform plays a critical role in tracking progress toward the company’s ambitious goals – a 50% reduction in carbon emission intensity by 2035 and Net Zero by 2050. With automated ESG data capture and reporting, Jindal Stainless ensures its sustainability performance is verifiable, stakeholder-aligned, and future-ready, solidifying its position as a leader in responsible manufacturing.

QuPID Manufacturing Award 2024

Awarded by Pro MFG Media in the Product Innovation (Large Segment) category, recognising JSL’s breakthrough advancements in product design and development.

Excellence in Manufacturing Process Award – 2025

Conferred at the 4th Future of Manufacturing Summit by UBS Forums, this award highlights JSL’s leadership in process optimisation and operational efficiency.

IMC Ramkrishna Bajaj National Quality Award 2024

One of India’s most prestigious quality awards, acknowledging JSL’s commitment to total quality management and customer satisfaction.

Quality Excellence

Award – World

Quality Congress

Recognises JSL’s consistent focus on quality systems, innovation, and performance excellence across manufacturing operations.

Data Privacy

and Security

As digital transformation continues to shape business ecosystems, Jindal Stainless remains committed to safeguarding the trust of its stakeholders through a strong, proactive cybersecurity and data protection framework. The company recognises that protecting digital assets and sensitive information is critical to business continuity, regulatory compliance, and long-term stakeholder confidence. JSL’s Information Security Policy applies to all affiliates and individuals with access to its systems, including employees, contractors, and third-party partners. To learn more, please visit Jindal Stainless’ website (www.jindalstainless.com). The company’s cybersecurity programme is guided by a company-wide Information Security Management System (ISMS), certified against ISO 27001:2022. This system provides a structured approach to identifying risks, implementing controls, and continuously strengthening the defences in line with evolving threats and international standards. The achievement of the ISO/IEC 27001:2022 certification marks a significant milestone in its ongoing commitment to information security, upholding its goal of zero cybersecurity breaches, and aligning with international compliance standards. Driving this framework is the Cybersecurity and Data Protection Committee and the Chief Information Security Officer (CISO), who are responsible for defining and executing JSL’s information security vision and strategy. Their efforts are supported by the executive leadership, ensuring that security remains embedded across all levels of the organisation.

Cybersecurity and Data Protection Committee

Steering Committee

The Cybersecurity and Data Protection (CSDP) Steering Committee is chaired by the Managing Director or their delegate and provides strategic oversight and promotes a strong culture of security across all functions.

The committee oversees the development and implementation of JSL’s information security, privacy, and compliance strategy in collaboration with business units. It supports leadership in fostering a strong culture of data protection and security awareness. It identifies and mitigates security and privacy risks, including those related to cloud services, and escalates critical issues when necessary. It also recommends, reviews, and updates relevant policies, processes, and controls to ensure continued effectiveness. Additionally, the committee serves as the primary escalation point for incidents involving unauthorised access to confidential or personal data.

Operations Committee

The CSDP Operations Committee, led by the Chief Information Security Officer (CISO), ensures operational effectiveness, monitors risks, and implements corrective actions where necessary. The CISO directly reports to the senior leadership team, ensuring that key developments, incidents, and audit outcomes are escalated and addressed in a timely manner.

The committee is responsible for overseeing enterprise-wide security and data protection in alignment with legal, regulatory, and global standards. It ensures the integration of security strategies with business and IT objectives, approves compliance initiatives, and reviews key risks, incidents, and audit outcomes. It guides business units on compliance, evaluates programme effectiveness, allocates critical resources, and supports business continuity. It regularly updates policies, promotes awareness through training and communication, and reports annually to the Executive Committee or Board on its performance.

These committees bring together cross-functional leaders from IT, risk, compliance, HR, legal, and physical security to support a coordinated and enterprise-wide approach to security and compliance. As part of its ongoing efforts, the company conducts regular audits, risk assessments, and compliance checks. These measures are aimed at maintaining a high level of business resilience, data integrity, and operational continuity. All policies, processes, and governance mechanisms are periodically reviewed to ensure they remain effective and responsive to the rapidly changing threat landscape.

JSL’s strategy is designed to balance control and flexibility, supporting business objectives without compromising security. The company also ensures that all initiatives comply with the applicable laws and are aligned with the best international practices. It has established a clear and accountable grievance mechanism to address any concerns related to cybersecurity and data protection. All reported incidents are thoroughly investigated by designated personnel to determine root causes, assess potential impacts, and implement corrective measures to prevent recurrence. Employees and stakeholders are encouraged to report any breaches or grievances related to information security policies via the dedicated email address: cyberincidents@jindalstainless.com. This process ensures transparency, timely resolution, and continuous improvement in the company’s security posture.

Risks Identified Through

Internal Audit and

Vulnerability Analysis

As part of its ongoing commitment to strengthening information security, JSL conducted an internal audit and a vulnerability analysis during the reporting period. The assessment identified several key risks that could compromise data confidentiality, integrity, and availability. These include potential vulnerabilities such as the loss or misplacement of company-issued assets during travel or remote work, inadvertent mishandling of sensitive information by employees or third-party staff, and firewall configuration issues that may expose the network to unauthorised access. Additionally, ensuring compliance with the Digital Personal Data Protection (DPDP) Act remains an area of focus, particularly around strengthening consent mechanisms, clarifying data flows, and enhancing protective measures. Addressing these challenges proactively is essential to safeguarding data, maintaining stakeholder trust, and meeting regulatory expectations.

Mitigation Strategies

To address the identified vulnerabilities, the company has implemented a series of robust mitigation strategies. Policies have been developed and enforced to govern asset use during travel and remote work, including restrictions on USB access and the use of mobile device management tools like Microsoft Intune. Multi-factor authentication (MFA) and strong password protocols are in place across all user endpoints. Full-disk encryption for sensitive devices is being rolled out to protect data at rest.

On the organisational front, acceptable usage policies and non-disclosure agreements are in effect, supported by continuous employee awareness programmes. Firewall configurations undergo periodic reviews and updates, governed by defined management protocols. In preparation for DPDP compliance, the company is implementing consent frameworks and training personnel to ensure responsible data handling. These integrated controls collectively enhance the company’s resilience against evolving information security threats.

To ensure the effectiveness of the company’s cybersecurity framework, the company actively involves employees by equipping them with practical knowledge, clear guidelines, and regular training to help them identify risks, adopt safe practices, and actively protect the company’s digital and physical assets. Regular security awareness campaigns include:

- Email advisories

- In-person training sessions

- Phishing simulations

- Visual campaigns (e.g., posters, videos, etc.)

These initiatives reinforce JSL’s commitment to a secure information environment and ensure alignment with evolving regulatory, technological, and business expectations.